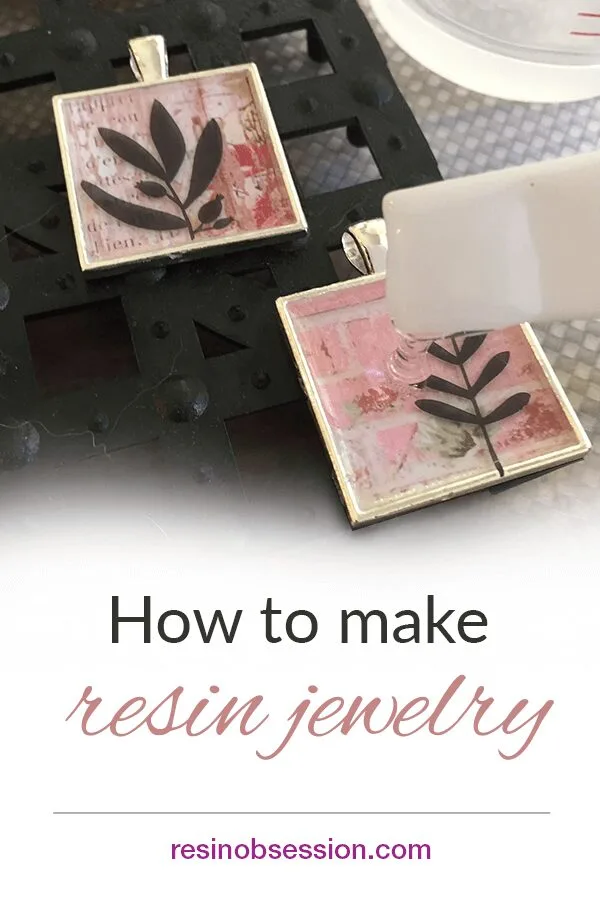

Here’s what you need to know about how to make resin jewelry that will make you look like a pro.

Step 1: Get ready for your project

Please don’t skip over this part. I get that you want to jump into a project, but I’m helping you avoid an ugly cry moment later.

Make yourself aware of your resin’s pot time and cure time.

Pot time refers to the amount of time you can work with the resin after it is mixed until it starts to cure. Don’t mix any more resin that you can comfortably use during that time. The cure time is the total amount of time needed for the resin to completely cure.

💡 Pro tip: There are many more terms you might run into when using resin. Bookmark this resin vocabulary page so you can refer to it later.

Choose your crafting area carefully.

Protect your table with a non-stick surface. Have a clear dome (like a plastic storage container) to cover your resin charms while they are curing. There’s nothing like a little dust or cat hair to ruin your curing resin.

Make sure your crafting environment is the ideal resin mixing temperature.

Resins best cure at a temperature in the low 70s Fahrenheit which could mean you may need to run the heat or air conditioning if your room is outside of these temperatures.

You need to wear gloves to protect your hands in addition to having adequate room ventilation.

Read these safety articles so you know how to properly handle and dispose of your resin.

If you want to cast your resin with something inside it, you need to prepare the item before mixing your resin.

Completely seal your image or finding with a clear-drying glue such as Mod Podge.

💡 Pro tip: How do you know if you need to seal something before including it in resin? Ask yourself if getting it wet affects the appearance. If the answer is yes, then you need to seal it.

Step 2: Prep your mold

When using a resin mold for a project, mist it with a light layer of mold release. This will keep the resin from sticking to the mold, especially if something should go wrong.

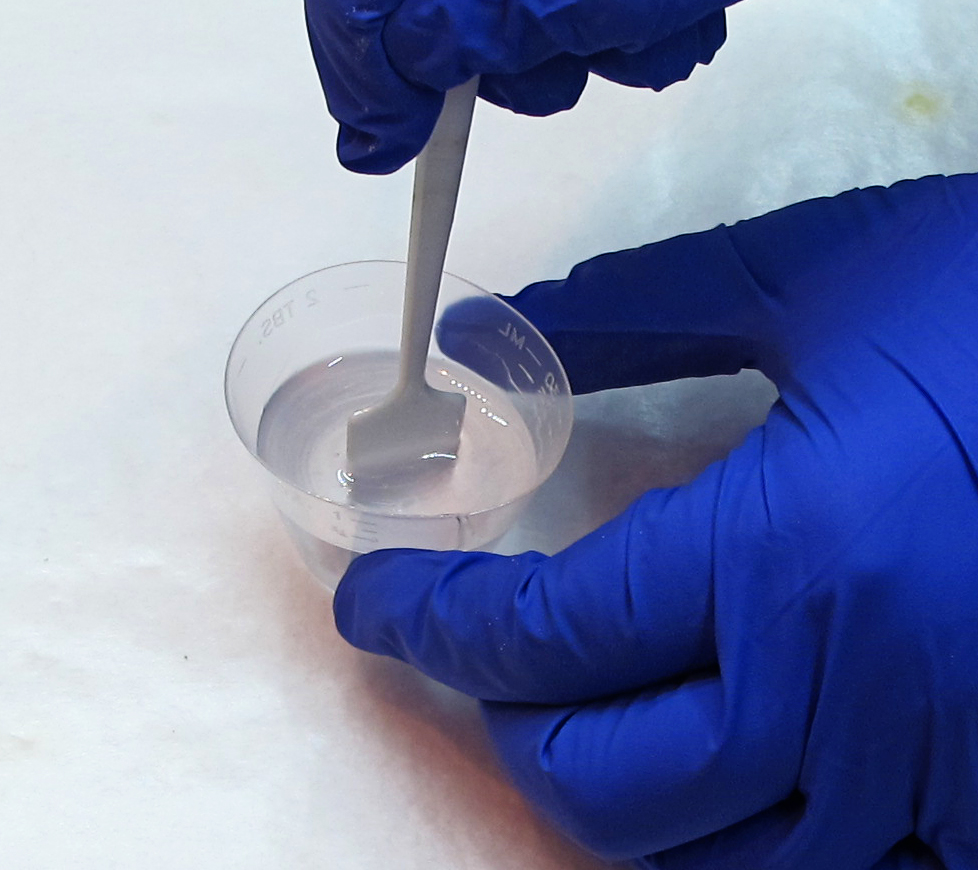

Step 3: Mix the resin

Follow the label directions. Precisely. You need to mix a specific amount of the resin (Part A) with a specific amount of the hardener (Part B). Don’t go a little more or a little less. Use graduated mixing cups so that you can be exactly sure of the amount you are pouring.

By the way, there is no set of universal resin mixing instructions.

💡 Pro tip: Use two separate cups for measuring; one for resin and one for hardener. If you over pour one or the other into separate cups, you can return it to its original container without contaminating your entire stock.

Stir the resin carefully with a stirring stick. While you should expect a few air bubbles, do not mix too roughly, or you will end up with more air bubbles than your favorite fizzy drink. Stir the cup for a minute or two, making sure you scrape the sides of the cup with your mixing stick.

The video below shows resin mixing in action:

Step 4: Color

If you’re adding colors, glitter, micas, etc., add a drop or tiny amount and mix. Add more if needed.

Step 5: Use it (or lose it)

Add the resin to your mold or bezel.

💡 Pro tip: If you want to add something (such as a bead or picture) pour a tiny bit of resin in first, then place your item in, otherwise, you may trap an air bubble underneath.

Step 6: Check for bubbles

Even if you carefully mix your resin, you’ll have a few bubbles to deal with. Use a heat gun to get the ones that stubbornly stick around. Some people use a propane torch or lighter, but not only can you start a fire (BAD), you can also damage your mold and it permanently sticks to your resin (MORE BAD).

Check your projects again several times over the next hour as more bubbles may have shown up.

Step 7: Finishing

Wait until your resin is fully formed before touching it. Then, you can demold them by gently twisting the mold while grabbing the edge.

Trim any excess resin with scissors or sand the edges with sandpaper. Start with a coarse grit wet/dry sandpaper (400 or 600), then work down to very fine grit sandpaper (1500 to 2000) to get a smooth edge. If you need to do a lot of sanding, sand the charm underwater so you do not breathe the dust. (Not you, just the charm.)

You can use a Novus polishing kit to give your cured resin an extra shine.

If you created resin charms, you will need to add findings to make them wearable. Otherwise, if you used ‘ready to wear’ bezels, you should only have to add a necklace, ear wire, etc, to be able to wear them.

Looking for more resources on how to make resin jewelry?

I wrote the resin ebook, Resin Jewelry Making, with the beginner in mind. I’ve concentrated on the details beginners need to know to make something you can’t wait to show off! Buy the PDF book now and you get a download link to your email in minutes.

Of course, the easiest way to get started is with a resin kit for beginners. It has everything you need to make jewelry the same day you receive it.

Unpublished Blog Posts of Resin Obsession, LLC © 2023 Resin Obsession, LLC

The mold shown in this article,silicone multi-cell, is not shown in your catalog-can you provide info?

In this tutorial the square mold you are using is this for sale

I would love to purchase one when they become available. Could you send out an email or something to let us know they are for sale? Thanks!

The square mold shown in the article is from my own collection of molds, but I hope to have some available for sale within a couple of weeks.

The square mold shown in the article is from my own collection of molds, but I hope to have some available for sale within a couple of weeks.

May I be informed when the mould shown on this page (the blue one in ready set pour) becomes available too?

Many thanks

May I be informed when the mould shown on this page (the blue one in ready set pour) becomes available too?

Many thanks

I’d also like to know when the mold on this page will become available for sale. Thx!

If I’m using a real flower do I put it in the mold first before I pour any resin and what if I want an open back bezel how would I do that.

Kathy,

You will want to add some resin, then add your flower. To do it with an open backed bezel, put your bezel onto a piece of masking tape and press hard. The tape will peel away from the cured resin. We have a video on youtube that talks about both of these: http://www.youtube.com/watch?v=WblAP-B6vPw&feature=plcp

I have noticed on ack of resin peices alot look like a solid color alost like a back was put on im not sure how to explain it?? almost like if someone used posterboard or soething? or some like whitle or clear like plasticy look to the back what is eing used to get to look so comercial or “neat”

Amy, a couple of questions:

What kind of resin?

Are there inclusions/pigments?

hello i really want to know what you NEED to make resin!

Sierra,

There is no way to make your own resin, but if you’re looking to get started with just the basics, I would suggest our beginners kit: https://www.resinobsession.com/ItemPage/5249/Beginner-Kit-Starter-Set-w-SuperClear-Resin.html It has just what you need to try out resin casting!

Dear Katherine,

what is the catalyst made from pleasei

@San,

Each catalyst is specific to the resin it is being used with. I would suggest contacting the manufacturer of the resin you are interested in and asking for the MSDS information.

i am buying Clear Round Epoxy Domes Resin Stickers, and want to add pictures to them? how? lol im a beginner

@Kaylyn,

This video on our youtube channel shows how to use epoxy stickers: http://www.youtube.com/watch?v=VqNQH2hD5mg

Hi! I have never worked with resin before, but I would like to cast organic material in powder form in resin and I plan to use a flexible silicon mold. Do you have any tips for casting powder? My main concern is that the powder may sink to the bottom of the mold (which will end up being the front/face of the pendant I’m making. I don’t want any of the powder to be exposed – I’d like it to be fully encased, yet visually fill the entire mold… Does that make sense? I appreciate any tips you can pass along! Also – which kind of clear resin is best for preserving organic matter? Thanks!

@Courtney,

The weight and density of your powder will determine if it will sink or not. I would suggest doing a couple of practice pieces first before attempting your final project. The Castin’ Craft Easy Cast epoxy resin or the Resin Obsession super clear resin should work well for your project.

hi

i am doing my ph.d in manufacturing engineering at tamilnadu. i need of air-set resin for sand casting, it is available with you? if not available means tell me the other manufacturer or suppliers information.

thanking you

@Senthil, unfortunately, I don’t have any information or experience to help you with your project.

I have some expensive soap molds made of poly plastic.. Really flexible stuff…If I use a mold for resin can I use the same mold after using it for resin to make soap..

@Connie, after using them for resin, I would not advise using them for soap again.

I used resin in my product so pls help me

Kathy,

I would like to create a resin replica of my beloved toy poodle “Peanut”. He is 5 lbs and apricot in color. Can you please advise what resin materials and molds will work best for me? Thank you!!!

P.S. Just kidding lol….some of the other comments/requests are funny!

Hi there, I am hoping that you can help me. I’ve been casting resin for a few weeks now, and progressively getting much better. Though i’ve notice whenever I clear cast something.. I have a very hard time with bubbles.. not big bubbles that naturally rise, or even smaller ones that come to the top.. but a persistent “haze” of super small bubbles (tiny, but enough of them to scrap my project). I’ve tried blowing them out of course.. tried applying the hair dryer when possible.. tried drawing them up with toothpicks (some are too small to even work with really).. but to no avail. I’m using EasyCast epoxy resin. Please… help!?

@Bexx, I would suggest more careful mixing to avoid creating the bubbles, or trying a different resin. The Resin Obsession super clear resin hardly ever has a problem with bubbles, but is only suitable for molds. If you need a doming resin, the Envirotex jewelry resin is a better choice. It’s meant to be poured in thin layers and almost never has a problem with bubbles either.

@Jeanne, I would suggest starting here: https://www.resinobsession.com/Resin-FAQ/320/Resin-Jewelry-Making—What-every-beginner-needs-to-know.html

I have never used resin before, but would like to create a resin form in which to secure a tree, as an art project. Do you have any information on line or for purchase that would help me get started ?

Hi Katherine,

I want to encapsulate flowers in their natural form, inside the resin in such a way that the flower do not losses its 3D form. How can this be done ?

@rohit, I would suggest using one of our sphere molds. You can find them in our geometric silicone molds section. https://www.resinobsession.com/Geometric-shapes.html

I’ve done two batches of pours. First one, all my pendants came out bubbly and not cloudy at all. Some of the pendants in second batch were all cloudy. Some pendants were partially cloudy. Some pendants came out clear. It’s really white, not just a little cloudy. I can’t see through it. (As in, polishing wouldn’t help, it’s cloudy inside) I’m consistent with mixing, use a plastic resin mold and coconut oil for mold release. Any ideas of what’s going on?

@Angela, Coconut oil isn’t suitable for a mold release. You need to use something designed specifically for resin casting. We have several choices here: https://www.resinobsession.com/Mold-Release.html

KATHERINE

Thank you so much i tried the acetone but a more gentle one (for taking off fake nails) worked quite well

Thanks

HI

i was wondering if there is any way to retrieve something that you put into resin that hardened some what but the surface remained tacky after five days of letting it cure .

this is something very personal and important to me and i followed the directions to a T read everything

before i attempted this .

obviously i should have done a practice piece but was assured if i followed all directions that it would be fine

so now i need to take it out if possible

thank you for you time

SUE

@Sue, if the resin has cured, but the surface is sticky, I’m afraid it’s unlikely you’re going to be able to get the piece out. You can try to recoat with another layer of resin. If your piece is still goopy, you can try a strong solvent like alcohol or acetone to get the finding out. Be sure to wear gloves and work in a well ventilated area if trying this.

Hi i have a few questions i hope someone can give me advice.I am fairly new to resin making but have made some lovely pieces with real flowers etc.How do i make a whole dandilion seed head cast in a round resin mold,do i spray it first or something?(so im prepared when they do come out!)couldn’t find it online anywhere! i’ve just used my mold for leaves-looks good except cracks around the edge on one side,possibly not dry enough? Also i thought a little fluffy white feather would look nice in a mold but it came out invisible! I want it to look natural so don’t want to color it,any ideas?Thanks x

@Emily, I’m not clear — are the cracks in the leaves or in the resin?

Ok thanks will try that.I attempted it again with something i knew was totally dry (in the sphere mold like before)but the cracks appeared again,seems to be the top half.I think it shrinks but i fill it as high as possible.i’ve had trouble sanding items too,it just goes cloudy looking and ruins it,even when i spray it after 🙁

just wanted to add its only the sphere mold i get cracks as it sets,i make other bits at the same time in smaller molds which come out fine

@Nur, I don’t understand the question. The resin ready for what?

Is there a specific way to tell if the resin is ready? Like by the colour of it looks or if I had poured too much of one portion? Help please ><

Hello, I would like to cast some small pieces of broken pottery in resin. I have no experience with this. How should I proceed?

Thank you!

@Laurie, I would suggest casting it as a found object. Here’s an example in this tutorial using glitter and transparencies as found objects: https://www.resinobsession.com/Resin-Tutorials/316/Glass-glitter-resin-pendant-tutorial.html

Fabulous site Katherine!! Loads of information! I am a newbie and want to make real leaf earrings. Do you have a tutorial on something similar to this? I have questions like does the leaf have to be dried out or dehydrated? Does the leaf have to be dipped in the resin or brushed?

@Lori, this tutorial on our blog should help: https://www.resinobsession.com/Resin-Tutorials/518/How-to-use-dried-flowers-in-casting-resin-charms.html

Hi Katherine thanks for all your awesome work!

I was just having some trouble with my embedments sinking when I wanted them to be suspended in the middle of the resin (and at interesting angles). They are made of all different materials – some metal, some plastic, even glitter sinks as well. Have you got any advice for me?? Thanks for any help!

Hi Nicole, you are going to have to pour your resin (and embedments) in layers. You can see what I’m talking about in this bracelet tutorial that uses buttons: https://www.resinobsession.com/resin-tutorials/button-bangle-resin-bracelet-tutorial/

How do I remove or polish a resin piece to remove the hazy look it received from my silicone mold? I used ice resin in a half circle mold and curved or “top”side is covered in a haze.

Hello Katherine,

I am new to using resin and I am making pendants and earrings with sand. I have some white sand from Destin and when I pour the resin over the sand it darkens the white sand. Do have any recommendations on how to keep the sand white and other light color sands light?

Thank you very much!

Thank you Katherine,

Can the gloss sealer be used on jewelry after the piece has been cured?

Dear Katherine,

Briljant website, very informative. Thanks!

I was looking around for more eco friendly resin, do you anything, like a brand name or something, that would be good?

Thx, cheers

I would really like to know this too please. Ive herd of pine resin but can’t find where its sold. looking to create eco friendly stuff. Any help please.

If i received an Alimilite super casting kit as a present will i need to get a bottle of clear casting resin for jewelry pieces as well? Or is the resin that comes with it clear enough?

The resin in that kit will cure opaque. You will need to purchase a clear resin separately. We have several here: https://shop.resinobsession.com/collections/resin

I’m wanting to put a piece of lace in resin for a necklace, do you have a tutorial for this? How would I go about doing this and what would I seal the lace with?

Hi, I want to make little resin spheres, with glitter in them. Is there a certain type of glitter I need to use and a certain type of resin or do most work?

Hi Amy, I would suggest the Resin Obsession super clear resin. It mixes in a thin viscosity, which makes it ideal for molds. You can see how I used it in this video on our youtube channel: https://www.youtube.com/watch?v=XNSvffZ-il4&t=1s

Hi, I am doing jewerly with wins of butterflies but I believe i didn´t do it right (sorry for my english) because my resin feels a little sticky but I already leave the thing dry a entire day and I don´t know if that is normal…

I also wondered if I have to polish the pieces so that they do not feel sticky anymore.

Without knowing which resin you are using, it’s hard to say, but I wouldn’t expect it to stay sticky after a day. If it’s only a little bit sticky (like tape) you can recoat with another layer of resin without having to sand.

I’m planning to make some wood and resin rings. Any suggestions on how to include flowers in the settings, will they go brown, should I dry them first?

Hi Deb, yes, you will need to dry and seal the flowers before using them in resin. We have a few articles on how to do that here: https://www.resinobsession.com/tag/drying-flowers/

Hi, thank you for the detailed explanations. I would like to have tricks about hair keepsakes. How can i shape the hair in the resin? I want to make letters from hair like “G”, “Y” etc. But the material is too rigid to give folds.

Hi Jasmine, there might be some pointers in this article that will be helpful: https://www.resinobsession.com/resin-tutorials/how-to-make-pet-hair-beads/

Hi! I’m having trouble understanding sealer sprays. I need a spray that will seal fresh flowers before putting them in apoxy resin. Is acrylic spray okay for this? Most sprays just call themselves “sealer” so it’s hard to judge different brands. Is this spray different from the spray I would use to finish apoxy resin to provide a shinier finish? I haven’t even started my jewelry quest yet. Waiting for my beginner products to arrive by mail!

You don’t want to use fresh flowers in resin. Even if you seal them, they will still rot. We have a few articles on how to do that here: https://www.resinobsession.com/tag/drying-flowers Once they are dry, this is the spray I like to use to seal them: https://shop.resinobsession.com/collections/tools-and-supplies/products/castin-craft-gloss-resin-sealer-spray?variant=965319185 If you cannot get this spray (we can only ship it to the continental U.S.) an acrylic spray is a second choice.

Can I brush some resin onto an object to strengthen it?

While the resin can help to make it glossy, I’m afraid it isn’t going to do much to strengthen it.

Thank you for your response. I want to make shell jewelry and there is a type of shell I found that is extremely delicate. I guess I will have to put it into a mould.

I can’t seem to get my resin to dome over my glitter in my necklace. I saw it on a 5 min craft video, and they put something on it before the glitter. When I asked what it was the reply was just because, which was not helpful at all. I do have the domeing resin

Have you seen this video on our youtube channel? https://youtu.be/MrVj4JSpPzI

What about placing beach sand in a bezel pan. Do you mix the sand with the epoxy or place epoxy-sand-epoxy or sand than cover with epoxy.

You can do either.

I am trying to cast postage stamps in a mold to make earrings. I’d like to have about 1/8 of resin on front and 1/16 on back so the earrings aren’t too heavy. My problem at the moment is that the casts have sharp back edges~ Opposite of doming, they are cupped down. How do I solve? Sand, use a different resin? ( I am using easy cast).

Hi Chris, I’m afraid that sharp edge occurs when casting with resin. You are going to have to sand the edges down. This article explains more: https://www.resinobsession.com/resin-frequently-asked-questions/how-to-sand-resin-smooth/