But then again, it might not be.

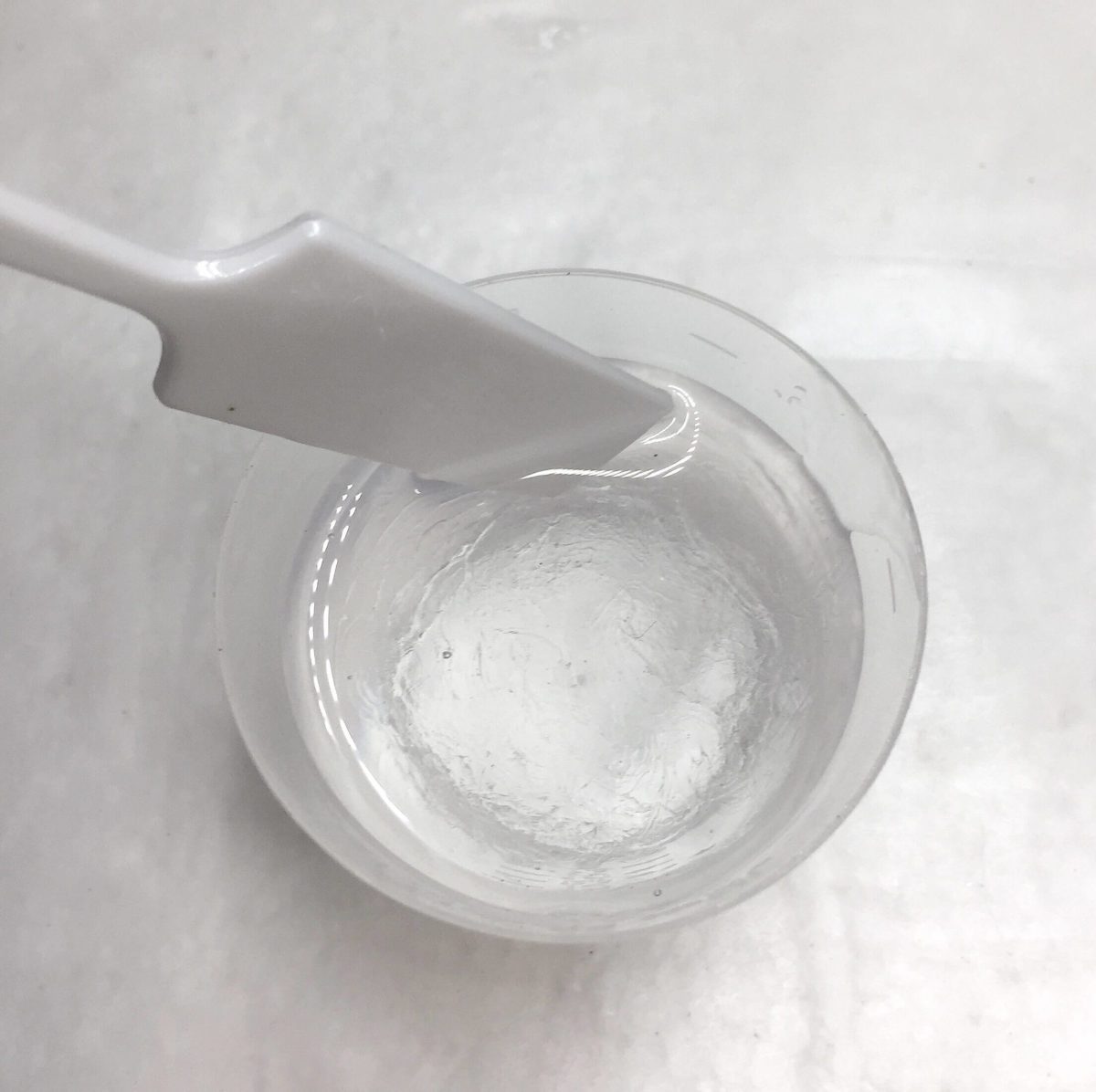

Normal: Mixing resin and hardener liquids together.

When you first mix two-part resins together, you should expect to see wavy resin. Because the two parts of a resin kit are different liquid consistencies, these look like swirls when you mix them together. As you continue mixing them together, these swirls will disappear.

💡 Pro tip: Seeing the wavy swirls disappear is one of the ways you will know if your resin is well-mixed.

Not normal: Waves and swirls in cured resin

Now if you’re asking yourself why is my resin wavy and the resin is cured, that’s a problem. Here are a few reasons why that happens:

1. The resin wasn’t mixed completely

You need to mix the two liquids until it’s clear and streak-free. The time this takes depends on how much resin you’re mixing at once.

2. Your resin is cold.

Sometimes, resin components can crystallize when the kit gets too cold. These crystals can show up as swirls or waves in resin. Before using the kit again, warm it in a warm water bath.

3. Moisture contamination.

This usually comes from something like glue or other adhesives contaminating the resin. It can happen if papers and other findings aren’t completely dry before you add them to resin.

4. Waviness can sometimes show up on the top of cured resin because it got too hot.

If you’re pouring large amounts of resin at once, you’ll need to find a way to control the heat.

Want to learn more about topics like why is my resin wavy?

Then you will want your copy of Resin Fundamentals. Learn from my seventeen years of experience as a resin artist. The ebook takes you from confused to confident when working with resin in only an afternoon. Buy the PDF book now and get a download link to your email in minutes.

Unpublished Blog Posts of Resin Obsession, LLC © 2023 Resin Obsession, LLC

Excellent guide line

Hello! After doing all this my resin is still wavy and has lines on it after it has cured.

Hi, you may want to reach out to the resin manufacturer directly for help.

I want swirl in phenolic resin please tell me method