So you’ve played around with resin long enough that you want to try mold making. High five. 🙌

When it comes to making a resin mold, here’s where you have to start:

You need a model.

Let me repeat it.

You need a model.

For you to make a mold of something, you must have a template to mold. You cannot carve out silicone or create a shape in the silicone without a template.

Unless you’re talking about 3D printing a silicone mold, which isn’t what we’re talking about here.

So how do you get a model for making a resin mold?

Almost anything can serve as a model. Here are a few examples of suitable materials for models:

>Wax

>Metal

>Clay

>Bone

>Plastic

>Wood

>Plaster

>Stone

>Other resin castings

⚠️ IMPORTANT: Be sure you aren’t violating any copyright laws. While it’s one thing to mold and recast someone else’s design for your personal use, it’s another thing to recast something and sell it. If you’re unsure if your model is legal for you to use, then don’t resell anything you make with that mold.

What happens if you have an idea for making a resin mold but don’t have a model?

You must create your own.

How do you do that?

Here are 3 ways to create a model for resin mold making:

1. Let’s say you want to make a resin paperweight that measures two inches square by 1 inch tall. Look for a woodworker that will cut, sand, and polish a wood piece that can serve as the template for your mold.

2. Have a more complicated design? Find someone experienced in CAD/CAM work who can create a wax prototype for you. Wax models are great templates for silicone molds.

3. Good with a computer? Some companies let you upload a design that can be printed as a three-dimensional object. In fact, 3D printing is so popular now, you might have local options. Print it in something like plastic to easily allow it to become the model for your next mold.

Now you have a model. What’s next in making the resin mold?

1. Build or secure an appropriate mold container for your piece. Empty plastic food containers make great mold boxes. They’re inexpensive and usually very flexible. If you build a mold box, make sure all sides are leakproof.

2. If your model is porous (wood, for example), seal it before using it with a mold-making material. Otherwise, the mold material may stick, making it impossible to demold later.

3. Before pouring in the mold material, cover your model with a light coat of a release agent.

Uh, this pouring silicone looks really hard. Is there something else I can try for making a resin mold?

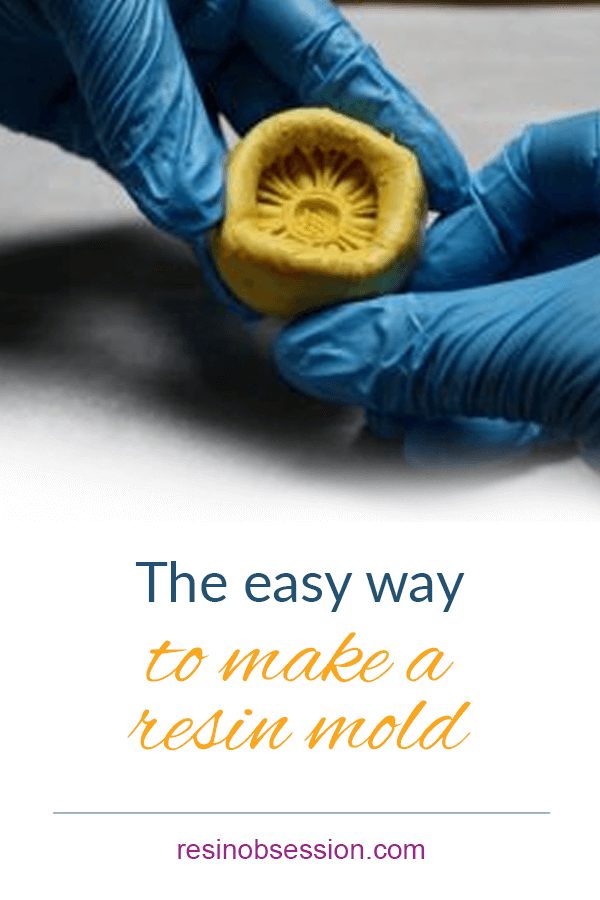

Yes! Two-part silicone mold putty is easy to use and can also make great molds. This shows how easy it is to use the putty.

Want to learn more about the basics of epoxy resin?

Then you’ll want to grab the ebook I wrote especially for resin beginners. In a couple of hours, you’ll go from confused to confident with resin. It’s the PDF book I wish I had when I started. Buy now and get a download link in minutes.

Unpublished Blog Posts of Resin Obsession, LLC © 2023 Resin Obsession, LLC

One of the reasons I want a 3D printer is so that I can make mold models entirely my own. I’m not all that good at sculpture but I can do stuff with computer graphics.

This is great info!! Thank you!

You are welcome. 🙂

is composimold safe if i will use polystyrene materials (miniature car parts, accessories, assorted model kit parts) ,im having doubts maybe it will melt.

I’m not clear on what you want to do. You want to use polystyrene made models to mold with Composimold?

Which types of silicone make the best molds for resin?

Hi Gen, it depends on what you are trying to mold. I’m afraid there isn’t a ‘one size fits all’ answer.

Hi. Thanks for all the advices. I have three questions:

– in order to have a glossy finished resin product we need to have a glossy mold so Which material of model is best to achieve a glossy mold?

– After made my mold, I tried casting it with resin but it has a lot of bubbles rough bumpy surface, like a sandy feeling when you touch it. What did I do wrong do you have any idea?

– Which material is best for mold frame? The design I try to mold is big and there is no plastic container can fit it!

Thanks

Hi Crystal, you will need to make your model out of something that can be polished. I’m sorry to hear you are having bubble troubles. This article will help: https://www.resinobsession.com/resin-frequently-asked-questions/resin-bubbles/ As for a mold frame box, you can try making your own with Tyvek pieces.

Thank you so much for replying to my msg. I didn’t expect it happened so quick.

I just read those points in the link, will give it a try but just another question to reassure myself. So the type and mould I used won’t create the bubble in resin? I did a test, if I sprayed mould release agent it would give a bubble rough surface, if I didn’t it would come out fine but not shiny.

Would cardboard paper or construction paper be a good choice for a mould frame?

Do you have any mould making classes? I would love to join. Thanks

Hi Crystal, the mold shouldn’t create any bubbles, unless it is one made from mold putty. Sometimes those can trap air bubbles, but you can bake it in a warm oven for an hour or two to get the bubbles out. If using mold release causes a frosted finish on your resin, then try using less. Unfortunately, cardboard and paper aren’t strong enough to serve as a mold box. I don’t offer any mold-making classes at this time.

Hi Katherine,

Sorry for being annoying but I tried for an hour looking for Tyvek and still don’t have any clue what is that. As I mentioned I need something to build a mould box/frame when doing silicone mold. Plexiglass a bit hard, can’t do curve or round. 😭

TIA

Hi Crystal, you can buy Tyvek at home improvement stores.

How make a holographicmold to make castings holographic as well?

Hi Hershey, we’ve got holographic molds in our store here: https://shop.resinobsession.com/search?q=holographic*