When it comes to using molds with resin, you might be wondering if you can use any mold with resin. Sometimes they work. Sometimes they don’t. And sometimes they fail badly. Like casting resin in a soap mold.

Spoiler: The mold didn’t make it. And the remainder of this article probably ends up just after #96 on this list.

💡 Pro tip: Be one of those resin nerds who’s always happy to try something new. Even if it means you can fail.

What resin to use?

Whenever you use molds, you need to use a resin meant for molds.

Why?

It ensures you get bubble-free results.

⭐️ BONUS: If you’re new to resin and molds, learn the right things to do in the beginner’s guide to epoxy resin casting.

Mixing the resin

Good resin nerd science dictates you should limit your variables. That way, if something goes wrong, you know exactly where to investigate. That’s why the resin is clear for this mold.

But, before adding the resin, the mold got a light application of mold release. Because mold release is something you should use to protect your molds whether you’re casting resin in a soap mold or not.

After removing bubbles with a heat tool, it sat for 24 hours.

Demolding

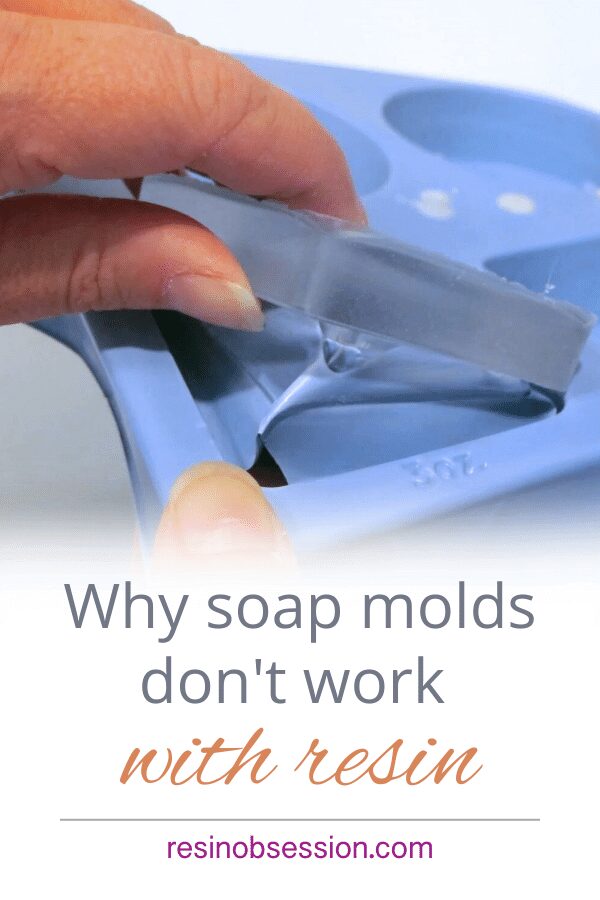

Soap mold plastic is thin. It is very similar in thickness and flexibility to a plastic take-out food container

The simple ‘twist and push from the back’ didn’t budge the cured casting.

With molds designed for resin, you can pull the mold away once you have a loose edge to lift the resin out of the mold. Unfortunately, doing that completely destroyed this mold.

Finished resin charm

Here is the final epoxy resin project. While the resin cured, it stuck to the plastic soap mold. In fact, most of the mold stuck to the resin.

💡 Pro tip: You don’t have to throw projects like this in the trash. Here are nine things you can do with your resin mistakes.

Are you tired of wasting your time and efforts to make something with resin you would never show anyone?

That can stop today. Instead, learn the easy steps you can take to make something with resin that will have people saying, ‘Wow, you made that?’

Buy the ebook, Resin Fundamentals, now and have the PDF book to read in only a few minutes.

Unpublished Blog Posts of Resin Obsession, LLC © 2023 Resin Obsession, LLC

Try putting the mold in the freezer, that helps sometimes in de-molding but you need to be careful if it is a really thin mold

Yes, have done that myself. Wanted to show what happens under what I consider ‘normal use conditions’ of a plastic mold designed for resin casting.

The worst I have tried is a candy mold. I had prepped it with release (the Easy Cast spray was all I had at the time), but then still needed to freeze it and wrestle with it to demold the pieces. The mold didn’t break but it was a major task to get the cast piece out.

That’s funny, I love candy molds. Especially when they are the dark colored ones–it makes it so easy to see what you are pouring. Have had no trouble de-molding. I have found baking molds to be terrible, however. My pieces all came out cloudy even with nothing added to the resin.

Thanks for taking on the many challenges that exist in the resin field. You make it easier for all of us to know what to use, how to use it & what to expect. You’ve saved all of us a lot of experimenting on our own. You are wonderfully generous and much appreciated!

🙂

I wondered if something in the particular mold release you used interacted with the plastic making up this soap mold being that it looks like it almost fused to the casting in the areas where you couldn’t get it off.

Great question! I don’t think that is likely. I believe it has more to do with the plastic type used for the soap mold.

I use Pam on molds that I have not made myself. It does not interfere, with the resin setting. I have never had a mold that I could not get my resin out of.

Hi Melinda, you have been lucky! I have found Pam is too greasy and can sometimes interfere with resin curing.

Can I pour resin on glass to make stained glass panels?

Yes.

thanks Katherine for doing the hard work of the experiments for usyou are a gem.

Lyndell

You are welcome. 🙂

Can I pour resin into a wire frame? Will it stick to the wire well? Maybe I can even weave it through. But in that case what would I set my mold on? seeing as it would be only molded by the shape of the wire instead of a real mold.

Yes, you can do that. We have an article on that technique here: https://resinobsession.com/resin-tutorials/wire-and-resin-jewelry-tutorial/

I have several silicone molds that I bought for candle making. Can I use these for resin instead? Thanks!

Yes, you can.

I once used a very decorative clear plastic carton that was used for rolls from the grocery store. I had leftover resin so what the heck?!! Demolding did not work. Tried freezing it but it wouldn’t budge. I ended up cutting the plastic mold away from the casting as close as I could (it was all clear with a star imprint in the center and scalloped edges). It actually came out pretty cool. I use it as a coaster 🙂

Love that you were able to save it!

So I’m just 17 getting into knife making and I want to make some micarta but need a resin mold I’ve only been here for a little bit but I need to know where I can get one please.

Unfortunately, I’m not aware of where you can find a knife mold. Have you thought about making your own?

I had a hard, thin plastic chocolate mold that I wanted to use for resin. I had a feeling this would be the last time I used it (and I was right). Once I cast the resin, I ended up having to tear the mold to pieces.

However, I then turned right around and used the castings to make a flexible silicone mold. Now I can make many, many more without struggling to demold.

can I use a silicone cup cake mold ?

Yes Shanthi, you can, but it may give a frosted finish to your resin.

Hello I’m new here and my little sister and I want to learn about resin as a shared hobby. We we’re looking into different molds and was wondering if a silicone chocolate mold would work.

Hi Faith, yes, you can use those, but they’ll probably leave a frosted appearance on your resin. This article explains more: https://resinobsession.com/resin-frequently-asked-questions/why-is-my-resin-cloudy/