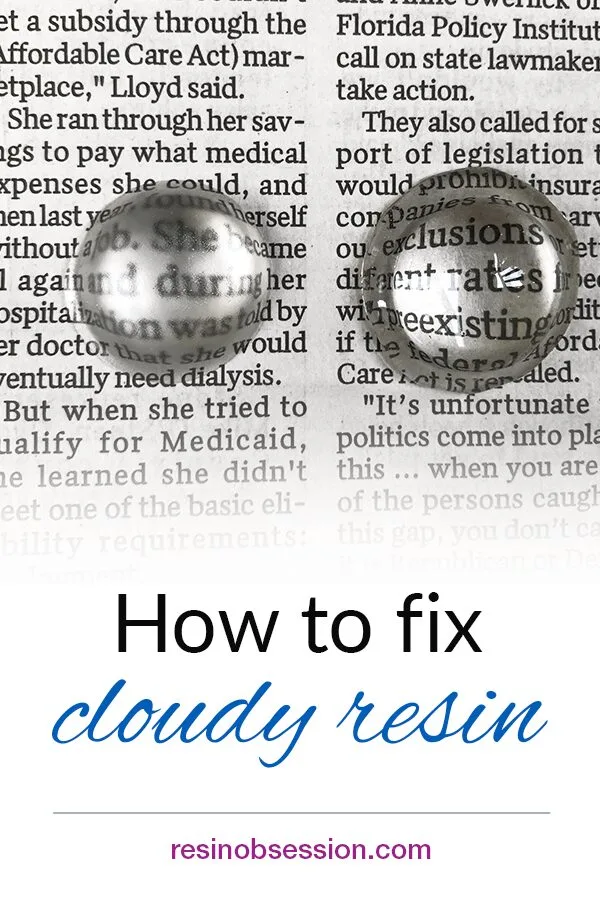

Step 1: Decide if the cloudy resin is on the surface or throughout your resin casting.

Surface resin cloudiness

In this situation, you have three options to fix your cloudy resin:

1. Recoat with a layer of doming resin

Use the resin like a glaze coating. Brush it over the surface of your cloudy resin and allow it to cure.

2. Apply a couple of light layers of resin spray and sealer.

This method is the best choice for resin projects that have a lot of grooves, irregular or curved surfaces.

3. Sand the surface and buff it with a resin polishing kit.

Resin cloudiness throughout

In this case, I’m afraid there isn’t a way to fix cloudy cured resin. The best you can do is to prevent it the next time you mix and pour resin.

1. Make sure your inclusions are completely dry before adding to the resin.

Water can contaminate your resin and leave cloudy streaks.

2. Warm your resin kit before using it.

This will dissolve any crystals that may have formed from your resin getting too cold.

3. Make sure to mix your resin and hardener thoroughly.

Incomplete mixing can cause cloudy streaks in the resin. If you are new to mixing resin, this will help: how to mix resin and hardener.

And if you can’t fix your cloudy resin, here’s what you can do with your resin mistakes.

Are you a resin beginner and confused by all the information you’re finding?

Like how do you know what to believe? Instead, go from confused to confident with resin. Get your copy of Resin Fundamentals, the ebook I wrote sharing my seventeen years of resin experience to give beginners a clear path to resin success in only an afternoon. Buy the PDF book now and get a download link in minutes.

Unpublished Blog Posts of Resin Obsession, LLC © 2023 Resin Obsession, LLC

Hiya! Unrelated question for you…how do you transition from the dregs of one set of resin bottles to a new set? I’m getting to the bottom of a set and don’t know how much is going to drain out and it looks like the resin an hardener have slightly different amounts in them. Can you mix easily with new product? Can I drain old bottles into new when enough room is available? Or…? I’m trying to get the best bang for my buck but don’t want to have a resin fail cuz I’m “thrifty”! 😀

Hi Frito, when I’m done with one bottle, even if there is some left in another bottle, I always start with fresh bottles of both. This article details how to safely dispose of unused product: https://www.resinobsession.com/resin-frequently-asked-questions/how-to-dispose-of-resin/

Ugh I’ve been having issues cloudy resin. I just bought a new mold, only used it one other time, second time it was clean and such, I poured my resin into that mold and it turned slightly cloudy, I also from the same cup poured another mold and that one turned out beautiful. Only difference between molds is one is a clear mold and other is the white-ish color silicone mold. Can that make a difference? Been having the same issue for awhile and it’s driving me nuts

Yes Rebecca, that can explain what’s going on. This article goes into more detail: https://www.resinobsession.com/resin-frequently-asked-questions/cloudy-resin-why-is-my-resin-cloudy-reasons-for-cloudy-resin/

Hi, I just stumbled on this site after an experimental project with resin. Which unfortunately (as you’ve probably guessed) turned out pretty cloudy I had washed the mold first and don’t think I dried it well enough… Is there a better way to effectively clean and dry molds? It also had a lot of tiny bubbles and I think that’s maybe because my mixer is very slow. Is it better to use a stick? As apposed to an electronic one?

Thanks for reading

I so want to be good at this, I’d love to buy your book but I’m in the UK…

Hi Tammy, I’m sorry things didn’t work out for you. This article will help with cleaning your molds: https://www.resinobsession.com/molds-mold-making/silicone-mold-care/ And this article will help with bubbles: https://www.resinobsession.com/resin-frequently-asked-questions/resin-bubbles/

BTW, my ebooks are downloadable, so they can easily hop across the pond to you. 😉 https://shop.resinobsession.com/collections/books

A pendant I made months ago has developed a cloudy surface after being shipped to customer. It was rock hard and super clear when I packaged and shipped it out (I use the crystal clear and doming resin depending on the project). I have no idea what would cause this, it has never happened to me in the 4+ years I’ve been working with resin. Now I’m worried about this happening to other pieces I’ve sold. He asked how to Polish it and I was surprised because it shouldn’t have been cloudy in the first place.

Hi Cassie, that is really strange! What do you use to package your jewelry for shipping?

Probably your resin get cold on the way or place had humidity during application.

I want ! Flat nonshiny surface on my resin. I am sealing outdoor concrete sculptures and Do NOT want shine! How would I achieve this ? Spraying with a fine spray of water? The sculptures are far too big and the surfaces are two uneven to sand after application

Hi Steve, you’re going to need to sand your resin. This article explains more: https://www.resinobsession.com/resin-resin-resin/matte-resin/

I can’t sand it the surface has very fine texture that will sand off. I’ll experiment 👌thanks. I’ll let you know how it goes

we did a walnut live edge vanity top. In placing the vanity around the sink, it appears that the epoxy coating has lifted up in a small area, maybe 1/2″ – 1″ by 3″ -4″ long. That area is cloudy, looks like it has pulled loose from the wood. Can thus be repaired and if so how? Thank you

We made a table and clued beer caps down. Put a 3/4” edge all the way around. Mixed up a 2 part resin and poured in. Total of 8 gallons. We have a small section at one end that is cloudy and hasn’t dried after 3 weeks. Can I scrape out non cured and put new resin back in?