Leftovers. Sometimes you love them. (Thanksgiving leftovers SO GOOD.) And sometimes you don’t. (Not saving my scrambled eggs ever.) And having leftover epoxy is somewhere in between. But you don’t have to waste it. Here’s what to do with leftover resin.

You might just turn it into your next epoxy resin masterpiece.

1. Form the resin into a flower shape.

Rings are one the pieces of jewelry you can wear that you can admire while wearing it. So why not make a fun one that will grab attention? Pour resin onto a piece of wax paper, then let the resin partially cure. Once bendy, push the resin into a mixing cup to finish curing. Glue your flower onto a ring finding.

2. Do resin experiments.

How often have you wondered about … [insert your resin question here]. Make a list of these things you want to know, and then when you have leftover resin, start investigating. Here are a few of my favorite resin experiments:

Will cookies crumble in resin?

What happens when you use nail polish to color resin?

Can you use resin in a soap mold?

Let your imagination go here. And don’t be afraid to make mistakes. You’ll learn so much.

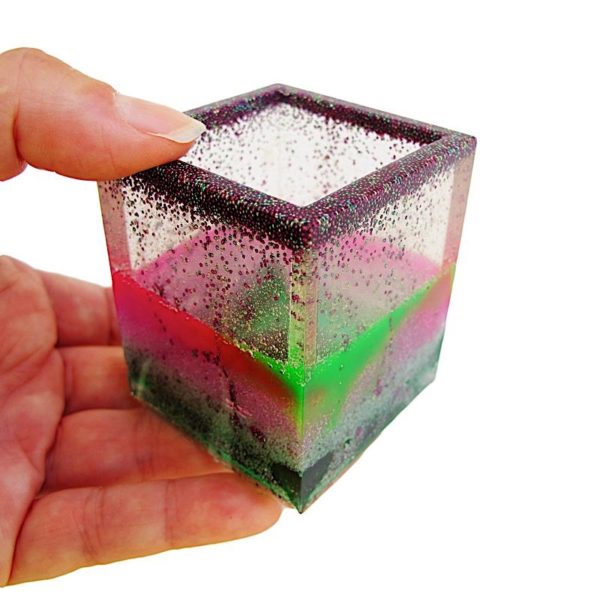

3. Pick a mold and pour leftover resin in it as you get it.

3. Pick a mold and pour leftover resin in it as you get it.

These are so much fun, especially in bracelet or vase molds. Who cares if the colors don’t go together or aren’t evenly poured into the mold?

4. Craft resin papers.

Have your extra resin ready to give a glossy coating to papers. What can you do with resin papers? You can…

Turn them into bookmarks

Make embellishments for resin journal covers

Add a magnet to make them the perfect refrigerator decoration

5. Make resin beads.

Spread resin over a non-stick surface. Once it’s soft cured, cut into strips. Then, roll them into a bead shape. Here are the full details on how to make resin beads.

6. Decorate a vase.

Take a glass vase from blah to bougie with your resin skills. Let the extra resin cure, then glue it to your vase’s surface. Here’s how with this leftover epoxy tutorial.

7. Use the resin as a glue.

Notice how resin sticks to everything? Use that to your advantage. Resin makes a strong glue. You can use epoxy to glue findings with a strong hold.

8. Let the resin cure, then reuse.

You can use cured resin bits as inclusions in your next resin project. Recycled resin bits add a pop of color in unique chunky patterns.

So what can you do to avoid leftover resin?

Use the Resin Obsession resin calculator. Take a few measurements, and the [FREE] calculator does the math for you on how much resin you need. It doesn’t mean you won’t have any leftover resin, but it can help you not have so much.

What if you don’t want to do anything with your leftover resin?

Then ensure you dispose of your resin safely. Set it aside to cure before throwing it away in your trash.

Want more epoxy resin craft ideas?

Then you’ll want a copy of the ebook, Ten Epoxy Crafts. You’ll get ten ideas for resin crafts for all skill levels. For less than the price of a resin kit, you’ll get resin ideas to keep or sell. Buy the PDF book now and get a download link to your email in minutes.

Unpublished Blog Posts of Resin Obsession, LLC © 2023 Resin Obsession, LLC

3. Pick a mold and pour leftover resin in it as you get it.

3. Pick a mold and pour leftover resin in it as you get it.

I love your ideas. Thank you for the emails. Been a busy year, so i save your posts in a folder, & catch up when i can. Resin is great! I also love polymer clay..Best Wishes.. Vicki..xx

Thank you Vicki!

thank you for your ideas — always informative and fun — I used resin to coat one of my Cosmos paintings once and the left over resin got me into making jewellery — which I am SOOO enjoying !!

That’s exciting Val!

I love everything mini. I pour up my little mini fish,paint them then add the 1cm fish to other items and put them into acorn caps off my tree and add more resin. I would like to sell some and would love for someone to tell me more about what price I should put on them