Pearl Ex by Jacquard is a powdered pigment with a touch of sparkle that exhibits extreme color-fastness (meaning it won’t fade when left in a place with bright light) and stability (the color remains true and does not change over time). Pearl Ex comes in a wide variety of colors. The colors are vibrant, and some even change color depending on the angle. The colors can even be mixed, dry or wet, to make new colors. Many colors have a metallic look, but since no metal is in them, they won’t tarnish. Others have a pearly luster.

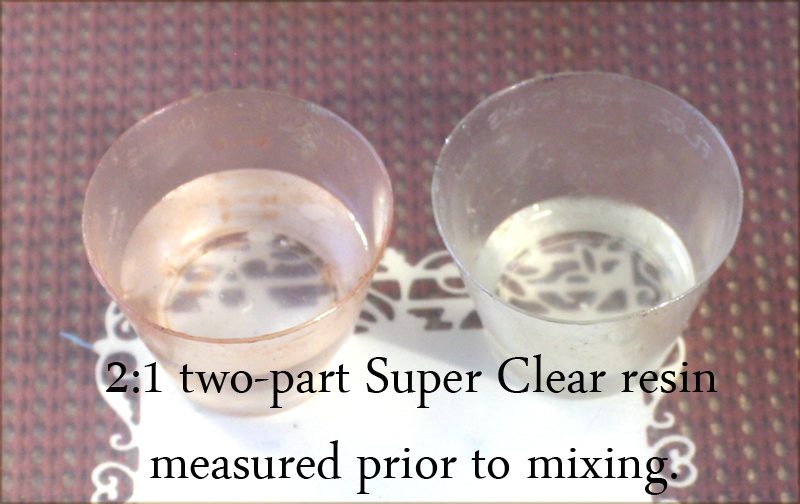

The resin we’re using today is Resin Obsession Super Clear. This is a 2:1 two-part resin with a 25-minute open or “pot” time (the amount of time you have from mixing the parts together to when it will start getting thick and non-pourable as it begins the hardening phase of the curing). This resin also has a 6-8 hour cure time at average room temperature.

Resin Obsession Super Clear is excellent when working with molds because its thinner viscosity makes it easier to pour and get into small places. The thinner consistency also traps fewer bubbles when working with resin molds. Super Clear also has a UV protectant to prevent yellowing over time. This ensures the color of the finished piece will remain the same as the day it was made.

Resin Supplies:

Resin Obsession Super Clear Resin

Pearl Ex powdered pigment

Leaves resin mold

Soft Paint Brush

Resin safety gloves

1-ounce mixing cups

Stirring sticks

Heat tool

Cover for the curing

Emory board

Safety Glasses

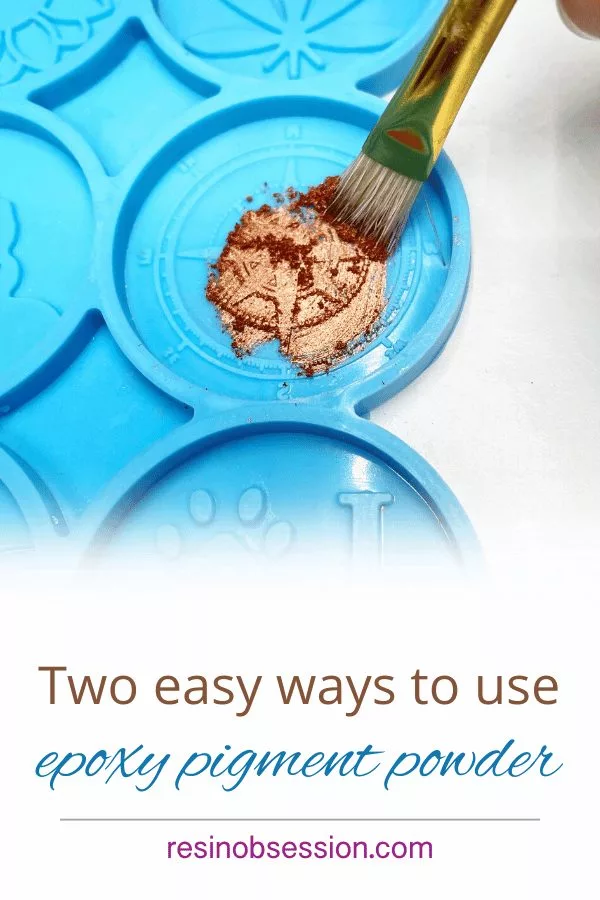

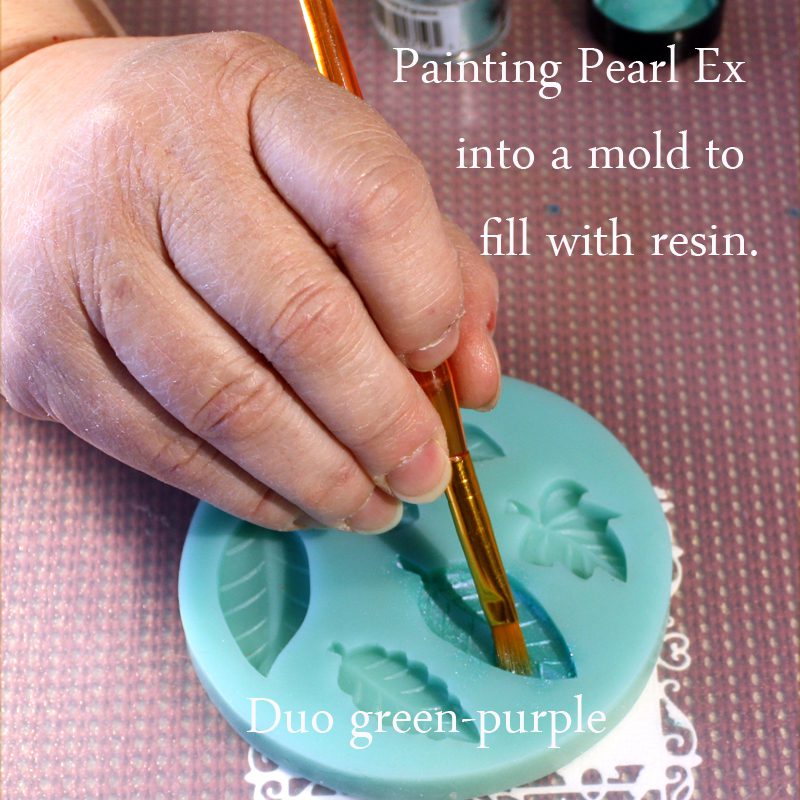

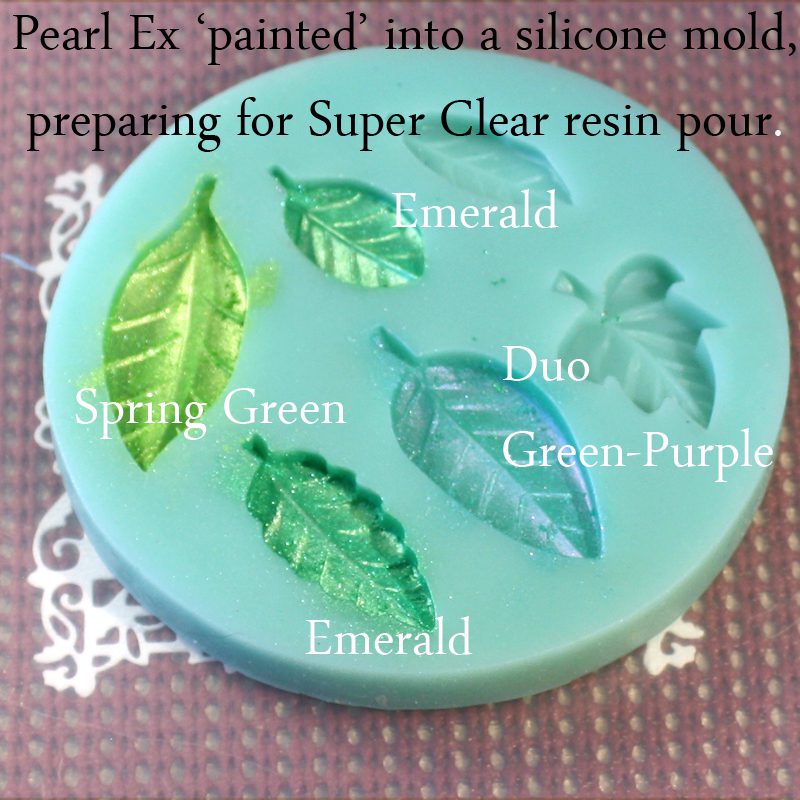

Option 1: Painting the mold with pigment

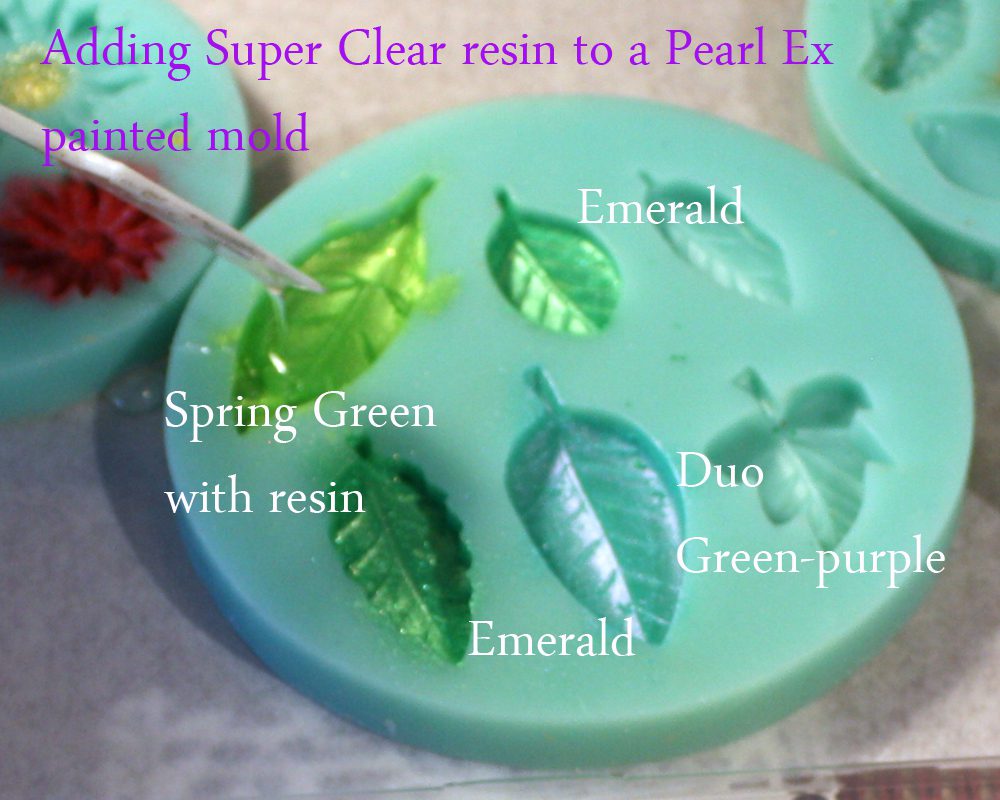

The method is one I often use because it allows the resin piece to be translucent while adding color and a bit of sparkle. It also allows the addition of color in an exact location. Before mixing your resin, you need to prepare your molds. Decide the pigment powder colors and the epoxy molds you want to use. You will also need a small soft paintbrush. I call this step painting the mold.

Step 1: Put powder on the brush

Dip the dry brush into the Pearl Ex to pick up a small amount of the powder and brush right into the mold cavity. You should brush on enough to cover the cavity on all sides but not so much that you have a lot of loose powder. Loose powder not in contact with the mold won’t make the coloring thicker or darker. It will likely just end up floating to the top of the liquid resin.

Step 2: Mix the resin

Resin Obsession Super Clear Resin is a 2:1 two-part resin. This means you use half as much of part B as part A.

Before mixing the resin, you should put on a pair of gloves. This will protect your hands from sticky resin.

When doing projects in small molds, I like to mix only a small amount of resin at a time so I don’t run out of pot time (the amount of time before the curing process starts) before I run out of mixed resin. Of course, if you run out of resin before you’ve filled in all the cavities, you can always mix more. I use 2 cups to measure the resin parts to ensure I get the correct amounts. Because they’re the easiest lines to see on the small graduated cups, I usually measure in drams.

If you have never mixed resin before, this is a good article for you to read: How to mix resin and hardener

Step 3: Add resin to the mold

When the epoxy is mixed, use the stir stick to drizzle it into the powder pigment painted cavities on the mold. Careful not to overfill. If you do, the back of the finished piece will not be flat, and you risk resin running over the side of the mold.

Option 2: Mixing powder into epoxy resin

The second way to use powder with epoxy is to mix it into the resin.

Step 1: Add powder to the resin

Pour a small amount of the clear resin into a dry cup. With a dry stir stick, dip into the powder and measure out a small amount, about the size of a pea. Drop the pigment powder into the cup without letting the stir stick touch the epoxy. If you want, as you mix, you can add more pigment using this stick. Do not put a wet stir stick into powder pigment.

Step 2: Mix in the powder

With another stir stick, slowly mix the powder into the resin. Mix in the powder until it is wet and looks like thick paint.

Step 3: Add the colored resin to the mold

Like the clear epoxy before, you want to drizzle colored resin into the mold slowly. Make sure you get the coloured resin into all parts of the cavity. The Pearl Ex mixed resin is thicker than the clear resin (also, you might be getting closer to the end of the pot time), so you might need to help it along a little to get into the edges. Use the stir stick to guide the resin where you want it to go.

Regardless of which option you took (adding powder to the before adding epoxy OR mixing powder with the epoxy), you’ll want to follow these next steps:

Step 4: Remove bubbles

To help reduce the inclusion of bubbles in the resin, you can use a heat tool or a lighter to pop bubbles on the surface. While many bubbles will pop on their own, you can use a toothpick or the edge of a clean stir stick to encourage bubbles congregating on the sides to pop.

Step 5: Set aside to cure

Cover your molds and wait for the resin to cure. It is always best to cover your curing resin because you don’t want dust, cat hair, or other unwanted things to become part of your project.

With Resin Obsession Super Clear resin, in 6-8 hours, the resin should be cured enough to remove from the molds, but you can wait longer to unmold them. I often let the resin cure overnight since it’s easier to wait for the cure when you can completely ignore it and aren’t thinking about how the project might turn out.

Step 6: Demold

Unmolding is one of my favorite parts of doing resin projects. This is when you get to see the magic of epoxy pigment powder.

Since we’re using flexible silicone molds for this project, you only need to bend the mold a little, and the casting should pop right out.

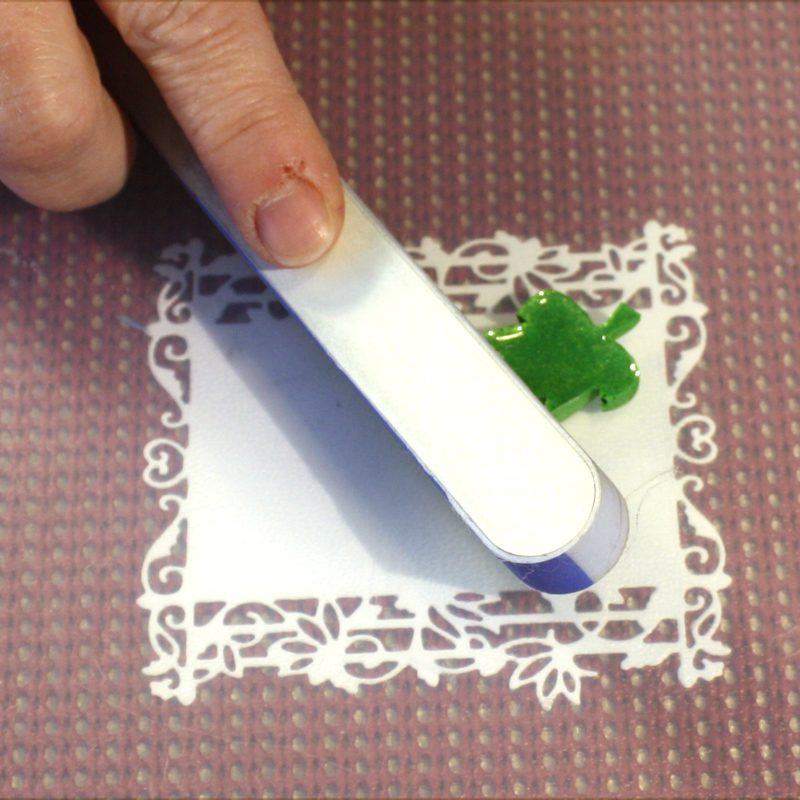

Step 7: Finish the edges

After you remove the casting from the mold, you will want to flip it over and sand off any sharp edges. You can use a small piece of sandpaper or an emory board. While sanding your resin, you should always use safety glasses and wear a particle mask to protect yourself from the grit.

When you look at the items you cast, you’ll notice the difference between the techniques. The ones in which you painted pigment powder in before adding clear epoxy resin have a slight transparency with sparkle (right). The ones cast with pigment powder mixed into the epoxy resin are entirely opaque and have a metallic marbled look (left).

The pair of shells on the left are from the same color of powder as are the pair on the right.

Step 8: Use your resin charms

So, now that you’ve made these molded leaves, shells, flowers, etc., what will you do with them? You can add molded items to mixed media projects and other resin projects, use them as embellishments on cards, add a glue-on bail and make them into jewelry, or many other things.

Some examples I’ve used the cast leaves for:

Want to learn more about using epoxy pigment powder?

Then you will want to get your copy of the ebook Resin Fundamentals. In only a couple of hours, you can learn the necessary details you need to know to make something beautiful with resin, even if you’re a beginner. Buy now, and an email download link for the PDF book arrives in your inbox in minutes.

Unpublished Blog Posts of Resin Obsession, LLC © 2023 Resin Obsession, LLC

You advise using a heat gun or lighter to get rid of bubbles. I’ve read where it’s not heat that “pops” bubbles, it’s carbon dioxide, hence you can exhale through a soda straw to get rid of bubbles. Which is it? Heat or CO2??

I have heard both as well. I have no doubt in the case of the heat gun, it is the heat that pops the bubbles.

I personally am not comfortable using high heat around a volatile compound so I haven’t tried that, but what I do with a project where I don’t want bubbles is two passes with a toothpick to pop bubbles and then just hold my breath to get it warm and then bend over and breathe gently onto the project without a straw. Gets rid of all of them. So I guess I am using both heat and CO2 LOL. Oh, and I don’t inhale after my exhale until I have stepped away from the project LOL.

I have used the breath technique to pop bubbles as well. You are right, in that you do not want to inhale the resin! I have never been concerned using a heat gun around resin, but the lighter method does make me a bit nervous. While I know some people do it, personally, I would never use an open flame around resin.

I just happened to receive a pair of leaf molds in a recent order and after reading this tutorial, I immediately tried painting the pigments into the mold before pouring clear resin into the mold. I used Ranger Perfect Pearls and what I immediately noticed is that the leaves came out with a frosted texture and translucent green color – almost like sea glass. I am working on a dragon’s egg using this technique and can’t wait to see the result!

I found a very nice old guitar in rubbish and want to get it back to playable, and looking good. There are mother of pearl inlays on the fretboard missing, and I cannot cut up replacements. Could a hard pearlescent resin fill the gaps, and if so, where to buy just around 20 ml or so?

Yes, I would expect resin to work well. You can buy a small quantity of the Resin Obsession Super clear resin here: https://shop.resinobsession.com/collections/resin/products/resin-obsession-super-clear-resin-3-oz-kit-jewelry-resin

How to get ths product

Hi, we have Pearl Ex powders in our store here: https://shop.resinobsession.com/collections/powder-colorants/products/pearl-ex-powdered-pigments

I’ve been on your site shopping:) but was wondering if you sell your pigments in a 12 pack or a starter set. I’ve got my order ready to go…

Unfortunately, we only sell the dry pigments in individual containers, not as a group.

Hello, would the resin rub off if you paint it in the mold first or are all the particles incorporated into the resin? Or is it advisable to add another clear resin layer on top of it for protection of the pearl particles?

As a pendant for example would need to withstand alot of handling/touching/fiddling.

I am looking for a very even pearly outcome, like a car finish. Thanks

Yes, it will work well for this.

Hello, would the pearl particles rub off if you paint it in the mold first or are all the particles incorporated into the resin? Or is it advisable to add another clear resin layer on top of it for protection of the pearl particles?

As a pendant for example would need to withstand alot of handling/touching/fiddling.

I am looking for a very even pearly outcome, like a car finish. Thanks

You can use it for this purpose.

I used the second technique, I follow the 2:1 ratio and everything looks good until it’s time to cure, I usually have to salvage using Mod Podge Dimensional magic on a tacky back but it takes well over a day to cure. I don’t think that’s right but done exactly know what I’m doing wrong. I know I should try the first way but I typically like the thick colors.

Hi Seth, we are sorry to hear things aren’t working for you as expected. We have responded to your email about this situation and are happy to help with technical support

I tried the painting with pigment and I absolutely LOVE the results! I used 3 colors on leaves at random. Did a rose also and it turned out beautiful!

Awesome!

I am new to resin and loving everything you have both tutorials and products! I feel like you really give everyone both newbies and pros the tools they need to be successful!!! Thank you for your time and effort in educating us all!!! Going to my work room to get started!!! Wish me luck!!!!!!!

Oh gosh Tracy, thank you!

Almost scares me to try. I just ordered some coloring. When it comes I will buy some resin and give it a try.

I love the look you get by painting the mold with the powders! Have you ever tried this? Painting the Pearl Ex into the mold, then adding clear resin, then dripping alcohol inks into the clear resin? Would the inks show thru the painted Pearl Ex layer?

Hi Cheri, do you mean like a Petri technique? If so, I wouldn’t expect it to show through the layer of Pearl Ex powder.

OK. Thanks so much!

Hi, do you have any method for the powder staying on the resin pieces? I make keychains and jewelry like necklaces, brooches, rings etc which are obviously made to be used, touched and so on. But I noticed the pigment wears off really quickly, faster on keychains as they touch keys or phone straps which attached to the phone are being put in a handbag among other items. I’ve tried many different powders as well as resins and the powders ALWAYS rubs off. I’ve tried to seal them with acrylic varnishes but that was not helpful at all. I know I could just dome them with resin, but I don’t want the high gloss finish. Maybe you know a product that could work for that? Thanks

Hi Anita, this is what I would expect for anything ‘high contact’ like a keychain, bracelet, etc. I’m afraid I don’t have any options for you if you don’t want a high gloss finish.

I love your work / videos – they’re very helpful. I’m struggling to find blues and greens – suitable for oceans. My white doesn’t seem to ‘pop’ either….maybe I need to add more of it…? It’s hard to know the correct measurement to use on 5ml of resin. I’m learning as I go, but I wondered – could you recommend any Pearl Ex shades please?

Thanks on advance. Sooz

Hi Sooz, I’m sorry to hear creating resin oceans are giving you trouble. I like to use the Resin Obsession pigments in our store: https://shop.resinobsession.com/collections/liquid-colorants/resin-obsession I use a combination of the transparent blue, teal and green to make the ocean water, then use the opaque white to make the ocean foam. If you want to give Pearl Ex powders a try, we have them in our store here: https://shop.resinobsession.com/collections/powder-colorants/products/pearl-ex-powdered-pigments. There are a few blue colors in there that could work for an ocean.

Hi, many thanks – I appreciate it. Do you have UK stockists please? I live in England.

Kind regards, Sooz

This is a really helpful tutorial — thank you so much! I just got some pearl-ex powder, but is it really OK to use it by coating/painting the mold without adding anything to help separate the resin from the mold? If I added something to the mold before applying the powder, for instance an oil spray, I assume that would adversely affect the pearl-ex coating? I have a relatively pricey silicone mold that I don’t want to break, but I really want to try this technique …

Hi Michelle, I’ve used the mold releases in our store with this technique and haven’t had a problem: https://shop.resinobsession.com/collections/tools-and-supplies/mold-release

When applying your pearl did you apply it afterwards or can I put it in the mold and add the resin on top?

Hi Julia, you can dust it in the mold, then add the resin.

Thank you for this instruction. I needed to know how to color the mermaid mold, now I can’t wait to get them finished.

I’m glad it was helpful to you Lorraine. 🙂

I haven’t been using resin for more than 3 months and I use either a plastic spoon or large wooden popsicle stick. I’ve learned that wood prevents bubbles. When I use a plastic spoon it takes less time to mix if I stir in a figure 8. Stirring too fast creates heat. People stir quickly because they know they have only 30 minutes pour time. Using a tool that grabs more in the stir will mix the 2 parts sooner which will allow about 3-5 mins extra to pour. That is golden. Also I feel the mini mixers are a really bad idea. They stir fast which creates friction/heat which cuts your pour time down in half. I just wanted to mention this for the newbies like me.