If you’re asking yourself, ‘What kind of resin should I use?’, let out a big sigh of relief. Because you’re in the right place to get that question answered.

And I get why you’re confused about what to buy. There are so many out there promising the life of pi in the sky. All the descriptions start sounding the same, and you don’t want to make a mistake. Or worse — waste your money buying the wrong stuff.

Hang with me. I’m going off-topic for a moment, but I PROMISE by the end of this article, you’ll know what kind of resin to use.

Sorry, fruitcake lovers, but that stuff is gross.

And even worse, you’re now the butt of the office party jokes, and your secret Santa gets you fruitcake gifts for eternity.

Do you see how you need an idea of what you want the cake for before you ever buy the cake?

The SAME THING happens with resin.

So if you were to ask me, ‘What kind of resin should I use?’ I’ll reply with, ‘What are you making?’

Because you need to know WHAT you’re making with resin BEFORE you buy it.

Just like that fruitcake, no one formula works for every situation. And anyone who tells you differently is a nickel-plated duck dollop.

💡 Pro tip: If you’re a beginner, I cannot stress here enough that you need to start with an epoxy resin. Why? Relatively speaking, epoxy is the easiest to work with. It’s the most forgiving of beginner resin mistakes, plus it’s the easiest to mix and measure.

So now you may be asking yourself, “What kind of epoxy should I use?”

Once again, it depends on what you want your final project to look like. Here’s the BIG THING to know the answer to when choosing a specific epoxy:

Are you filling a space or coating a surface?

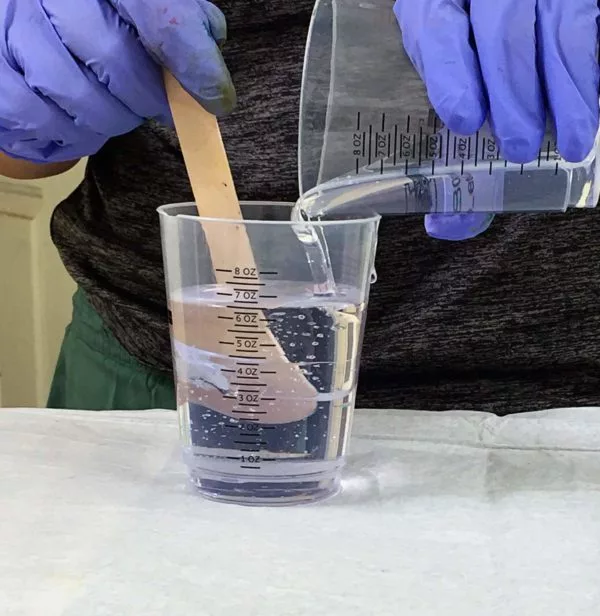

If you’re pouring it INTO something, like a mold or a space for a river table, you want a casting resin. These are low-viscosity resins that release bubbles easily that you can pour in thick layers. But because they mix watery, they will run off a surface, making fish eyes, so they aren’t suitable for countertops or artwork.

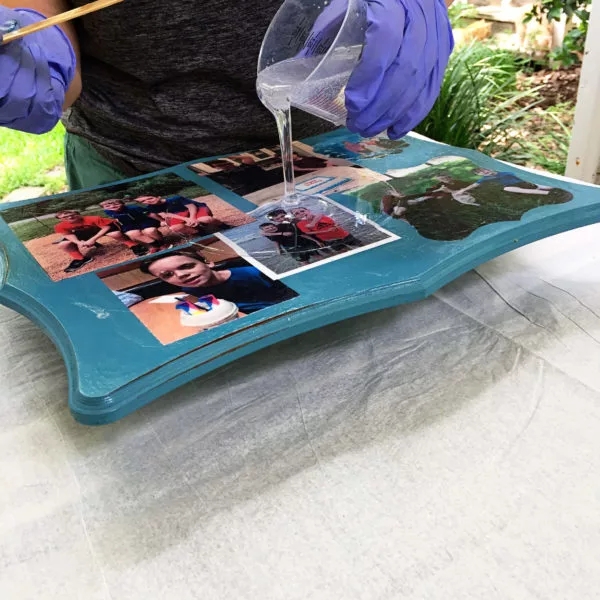

If you’re pouring resin ONTO something to create a glossy surface, you want a doming resin. This kind of coating epoxy is high-viscosity, so it evenly levels after applying to a surface. While it can run over the sides when added to a flat surface (for example — applying epoxy to a canvas print), it levels smoothly and gives a shiny finish. But, because it’s thick, it’s harder to remove bubbles. That’s why you don’t want to use it with resin molds or epoxy table projects.

⭐️ BONUS: If want to go down the resin rabbit hole on this stuff, I’ve got even more good stuff for you explaining the types of epoxy.

Like the differences between doming resins and deep pour epoxy

You’ll get all those details in our [FREE] Guide to Choosing a Resin

Awesome! You’ve picked a type. Now what?

If you’re wondering where you can buy clear epoxy, Resin Obsession has you covered. Choose from multiple formulas to help you make something amazing.

And this RESIN QUIZ makes it easy to know which formula you need.

Which epoxy should you use?

Learn which epoxy resin is the best one for YOUR project.

Now to be completely honest here, what we sell might be more than you need.

Like if crafting with resin is just a bucket list thing, then any resin can help you make that.

You don’t need one with

✅ top-notch UV protection

✅ the highest safety level designation

✅ made in small batches to give you the freshest product possible.

That big box store stuff that’s been there so long it looks like a doctor’s office urine specimen (might) work for a bucket list project.

But buy resin and supplies from Resin Obsession, and you’ll get the clearest, freshest stuff possible.

And as an added bonus, our resin kits are blessed with kitty kisses. At no charge.

If epoxy is so great, why would I use anything else?

Once you’ve got advanced skills, there are a couple of other formulas to try.

You might want to make a resin project that cures quickly.

In that case, you will want to use a quick-curing polyurethane. These usually fully harden in under thirty minutes, so you can make a project and have it ready to use or wear in under an hour. Unfortunately though, this formula is very moisture sensitive. Any amount of water will make the resin bubble and cure looking like a sponge. It’s also not a type I recommend for beginners since you only have 1 to 1 1/2 minutes to mix and pour it before it starts curing.

If you’re working in molds, you might want to try a polyester.

These resins cure hard and are generally cheaper than epoxy. But they STINK and don’t have a long shelf life. If you want to try it, here’s what else you should know before using polyester resin.

Want more help getting started?

It’s why I wrote the ebook, Resin Fundamentals. I designed it for beginners to get you from confused to confident in only an afternoon. Buy the PDF book now and get a download link in minutes.

Unpublished Blog Posts of Resin Obsession, LLC © 2023 Resin Obsession, LLC

Very informative, loved it. Thank you.

In case anyone else is a painter and is interested in what I use to coat paintings – I use Environtex lite and it comes out beautiful every time. I have coated small paintings as well as large 3’x4′ ones. Not a great idea to do on a wrapped canvas as pooling occurs.

What is the difference between Environtex lite and Clear Polyester Casting Resin by Castin’ Craft? I am a painter and I am looking into what’s best to coat my canvas paintings. Something that will give it a “glass topping” look. Thanks!

Hi Katherine!

I’m looking for something to coat on already finished jewellery pieces, sterling silver and titanium steel rings with cubic zirconia stones to prevent the stones from falling out.

I would like this coating to dry crystal clear so as not to affect the shine of the metak or stones.

Do you know o any coating that would do this?

Thanks!

You want the resin to go over top of the stones? I ask because that will make them less ‘sparkly’ because the light will refract differently doing through a coat of resin first.

Loved the details u gave so minutely about resin n its types Katherine. Thanx for sharing all this info. Do u know the answers to these Qs?

1- Hw to get UV protection in resin? Any method?

2- Details about silicone resin and acrylic resin? Pot time, cure time, sensitivity, temperature, etc?

3- Hw to clean the pot n brush used to mix n apply resin? Can the same pot n brush be used again for resin mixing n application?

4- If ease release spray is not available then what can be used?

5- If we apply resin on half side of surface n then after drying apply on the other half side, would there be a seperating line formed between both sides after drying or curing of both sides?

6- For the 2nd coat, only waiting for drying is enough or should wait for 7 days until entire curing of 1st coat is done?

I’m happy to help! Here are answers with numbers that correspond to your questions:

1. To get UV protection in resin, you need to buy it that way. That notation should be included in the product listing. If you don’t see it, ask the manufacturer.

2. Every resin is different in terms of pot time, cure time, etc. You will need to get the specifics from the manufacturer of the resin you want to use.

3. We have a video on our youtube channel showing how to clean resin:

https://youtu.be/17Ixaa0Lw6o

4. Vaseline can work as a release, but it may leave marks on your casting.

5. Yes.

6. Waiting until the second coat is dry, not fully cured, is sufficient for applying a second coat.

What is the coverage (sq ft) on the Total Clear Resin 70 ounce kit?

Approximately 40 square feet

The big differences between epoxy and polyester rein is the expansion and contraction under temperatures changes. Polyester is more brittle and is more sensitive to temperatures change, meaning will crack easiy. Epoxy has more options and types.

bubbles…some of the clear brands are bad for bubbling…so you have to get out the alcohol burner..pressure pot or whatever way to fight the bubble war. Then again some products don’t bubble as bad.

I’m a beginner at this. I’m filling small 6×6 acrylic boxes. Only needs to be 1/2 inch thick. So from the great info above I need to use polyester resin. Clarity is important and no bubbles. A logo is on the bottom of the box that will be covered with 1/2 resin

Hi Kim, you can also use a deep pour epoxy resin for a project like this. It cures slowly and bubble-free. You can get deep pour epoxy resin kits here: https://shop.resinobsession.com/collections/resin/resin-obsession-deep-pour-resin

This is a really good video to see the tinting with UV exposure

https://www.youtube.com/watch?v=MzIxcIqCNh8

Hi Tracy, unfortunately all resins are going to yellow with UV light exposure. While that video shows experimental conditions, it cannot account for every experience resin may face when used in a practical setting. While I think the results can be used as a guide, users need to understand and test the resin they are using to see if it’s going to work for their specific needs.

I just wanted to point out that you should still be using a respirator/mask of some sort at least (I’m not an expert so maybe stick with a respirator) when working with epoxy resin. It can still irritate your lungs, especially if you react to it! Check out Epoxy is Not My Friend on Facebook.

Hi, I wanted to make dried flower jewelry resin. One that is super clear, minimal bubbles, and one that doesn’t take out the color out of the flowers. Do you know which would be best? Thanks!

Hi Amy, properly drying and preserving the flowers are what’s essential to keeping the color in them. We have a few articles on how to do that here: https://resinobsession.com/tag/drying-flowers/

Which resin is better for casting Prosthesis & orthosis?

What would you recommend for starter projects like a cutting board or jewelry dish.

Hi Amber, we have a couple of beginner kits in our store here to help you get started: https://shop.resinobsession.com/collections/all-in-one-kits

Hi Katherine! You seem to be somewhat of an expert in all things resin. I have only ever used epoxy resin, but I am now making jewelry that are around 1/8 inch thick at most. My epoxy resin seems to only cure soft at that thickness. What resin type would you suggest I use to make something near that thick but be around as hard as glass? Please help.

Hi Derik, are you making jewelry in molds or bezels? That will best help me with a resin recommendation.

I make them in molds or thin sheets and carve/ sand the shape out myself.

Hi Derik, the Resin Obsession super clear resin is a good choice for a project like this. You can find it in several sizes in our store here: https://shop.resinobsession.com/collections/resin/resin-obsession-super-clear-resin

I appreciate the specific link you sent, but I was asking the type that would work best for this. Epoxy seems to be too soft for thin projects like this.

Hello Katherine! Thank you for all the info on the topic. I want to make personalized phone cases, the idea is to paint a clear plastic phone case with acrylic paint and then coat it with resin. What resin do you think would suit this work the best? I’m sorry if my english is not the best, i’m not a native speaker

Hello Valeria, for a project like this, I would use the Resin Obsession crystal doming resin. You can buy it in our store here: https://shop.resinobsession.com/collections/resin/resin-obsession-crystal-doming-resin

I want to put an old dried out rose on display in a sort of beauty and the beast type thing but in a tall square exposy/resin cast and very clear as a gift, I keep reading different articles because this is my first project ever using any resin and I would love some tips and help if you have any? I was wondering what type you would recommend to use?

Hi K, we have beginner tips here: https://resinobsession.com/tag/beginner/. As for a resin, the Resin Obsession deep pour epoxy casting resin will work great. You can find it in our store here: https://shop.resinobsession.com/collections/resin/resin-obsession-deep-pour-resin

Hi i have a question. I use Amazing clear cast. I make trays and coaster and cups. I have a problem where on my trays some of the resin gets on the back after I have painted it…how do I prevent this and how do I get it off. Also I normally have so much left over I do i measure it correctly

Hi Jan, it sounds like you need to tape off the back with painters’ tape.

I need help! I’m still confused.

I am a first time resin user, I want to do an art project with resin but I still do not know which one to use. What I had in mind, is that I want to make a cube. I’m thinking of starting small like a cube with all sides being 7.5cm long. I want the resin to be crystal clear. Which kind of resin would be best for me?

Hi Victor, for a project like this, the Resin Obsession deep pour resin works great. You can buy it in our store here: https://shop.resinobsession.com/collections/resin/resin-obsession-deep-pour-resin

Enjoyed your article. I bought Envirotex Lite high gloss resin. It was poured over stained glass pieces of glass glued to a window pane. I mixed exactly 1 to 1 as described and it did not totally harden. My research says I have to apply another coat but I am very nervous about doing so because I do not want to ruin my piece. It took a long tine to make. Do you have any suggestions.

Hi Joan, it’s been my experience that Envirotex Lite cures bendy. This article explains more: https://resinobsession.com/resin-frequently-asked-questions/why-is-my-resin-bendy/

Can you use different resins in multiple coats. ie. start with Poly resin let cure and than coat over the top with epoxy resin?

I am trying to get a hard plastic like rigid shiny finish on real dried orchids?

@Rich, I have layered with different brands of epoxy, but have never put epoxy over polyester for example. If you want to try, I would suggest experimenting with a couple of practice pieces first.

How many polyresin layers will it take to create hard glass like feel to coat real flower petals?_

By polyresin, do you mean polyester resin?

Does anyone kow of any reactions between uv resin and metal (copper in particular) and where to find the info. As when using them together recently the resin hasn’t been curing like normal and ends up rather sticky and still liquid inside???

Im a beginner to resin and want to embed bottle caps and make some coasters. I had the Easy Cast-which was prob at least a year old, and worked well. Low bubbles and nice and clear. I ran out, so I bought the Envirotex Lite-pour on. This is not as clear and full of bubbles. Is this the wrong type of resin for my project? What brand would you recommend or how can I clear up all the littles bubbles the muddled my coasters? Thanks!!

The best remedy for those pesky bubbles in the use of a blow torch. Works in instantly. removes them like magic. Just swipe over quickly. I’m told using a straw works good too.

I am using silicone molds and want to make make up trays, food trays, jewelry boxes and other gifts that use molds some are thick and some are not. I want it to be clear and hard like glass not rubbery what should I use?

Hi Mia, for pours of 3 ounces or less, the Resin Obsession super clear resin is what you want: https://shop.resinobsession.com/collections/resin/resin-obsession-super-clear-resin

For pours of 3 ounces or more, the Resin obsession deep pour casting resin will work: https://shop.resinobsession.com/collections/resin/resin-obsession-deep-pour-resin

The Envirotex is really meant to be more of a coating. It was probably too thick for the mold. Unfortunately, there is no way to clear up the bubbles in a casted product once it’s cured.

Hi Katherine,

Sorry I am posting this here, but I can’t get my computer to work on the forums….(something I’m doing wrong, I am sure).

I am trying to figure out something to coat some flat copper or brass blank sheets with. I’m going to use these as bases to pendents which I’m gluing random items onto. Since the flat metal sheet bases I’m using are unfinished I figured it would be nice to coat all of, or at least the back of it with an epoxy resin so that the person wearing it wouldn’t get an allergic reaction or have the piece tarnish due to sweat if the back was touching their skin.

Do you think epoxy resin would work for this?

Thank you so so much for your help!

-Kristina

Kristina,

I think epoxy resin would work very well for this. A few other things come to mind as well for possible use: wax (I like Renaissance wax), acrylic spray, maybe even mod podge??

Thank you so much for the response Katherine.

For Renaissance wax, if I were to use it on raw brass or copper – do you know how long it “stays” for? I’m assuming it wears off over time, is that an accurate assumption on my part?

Thanks again. You are the most helpful person I’ve found on the internet. And it’s a big world out here!

I’ll for sure be using this store in my near future.

Kristina,

I have used the Renaissance wax in the past to seal my sterling silver and resin pendants and have been quite pleased with the results. I always suggested to my customers that they clean with a soft cloth and a mild soapy water if necessary. I would suspect putting a good grease cutting soap on the pendant would take the wax off. I suppose with regular wear it would eventually need recoating, but I can’t tell you exactly when that might be. Glad I could be of help. 🙂

Hello Katherine,

Based on the comment above by Kelly, I am thinking that the Easy Cast is the best for my project because I am trying to cover a table top with bottle caps, but I just wanted to double-check it will hold up as well as a polyester one, that sounds like it is harder?? Many thanks!!

Chelsea,

It depends. If you’re looking at a layer of 1/8″ or less, I would go with the Envirotex. It’s meant for table top coatings, so it might be fine for your project. It will show some wear sooner than an table top poured with polyester, but it’s certainly easier to work with.

You could pound the caps flat with a mallet to make them thinner.

What resin to use??? I want to do a beach scene on canvas, using acrylic paint, glass, sand, small shells, etc. I’ve NEVER used resin, because not sure how to do this. Thanks for any answers you can give me.

Hi Judy, for a project like this, you want to use the Resin Obsession artwork resin. You can buy it in our store here: https://shop.resinobsession.com/collections/resin/resin-obsession-artwork-resin

Hello, I’m trying to make Apple Watch bands. I have the molds but not sure which resin to use that will cure and still be flexible. Is this even possible? I’m new to all this as you can probably tell 🙂

Hi Aimee, you need to use silicone resin for your project.

Hi Katheryn

I am a beginner too, can you advise what resin for a wooden bar top? I am painting the wooden top black and coating it in gold leaf sheets And I wanted to place resin over it. It’s quite a large room that can be ventilated. Thanks

Hi Ben, our artwork resin works great for a project like this. You can find it in our store here: https://shop.resinobsession.com/collections/resin/resin-obsession-artwork-resin

I want to cover a 3 foot diameter table with a clear resin. It will be going over small pebbles to make a table for outdoors. What would be my best option? A beginner, but I like to try new things.

Hi there, I’m wanting to start making resin charms with easy cast resin. Ill be working in a room that has an outside door, two large opening windows and two smaller windows. Ill make sure to open them when i use the resin. However I’m worried, will I need a mask? I live in the UK, and I have no idea what to look for in UK masks? Do you have any suggestions? Please help.

@Kerri, that should be enough ventilation for you if it’s the Easy Cast Epoxy resin. I don’t think it’s any more bothersome than using fingernail polish.

I’ve made a bunch of posts all over the place… I live in Maui and have had a hard time finding the materials I need. The only epoxy resin I can find is Parks Super Glaze. Do you have any feedback about this brand? It says it’s “ultra-thick.” Will this give me any problems with casting in molds?

And thanks for answering all my other questions I posted elsewhere! Really appreciate it… 🙂

You seem to be the Answer Lady! You have much wisdom and willing to share. Bless You & may Your kindness return to You & Yours 100 fold! I have a curious need. I am trying to ‘fill in’ the letters in a stepping stone my friend made me with ‘Beckys Place 2013’ drawn in concrete. I want to color pink resin and place 4mm darker pink swarovski chatons into the pour. Should I use the Envirotex Lite?

Hi Katherine,

I’m interested in making my own hair sticks using photographs I’ve printed on photo paper and cust out. What is the best type of resin to use to great a clear glossy surface that is also hard enough to use for a hair stick? Also, what method would you recomend for applying the resin? Domming or layering? Thanks!

Birgitta

@Birgitta,

I would suggest the Castin’ Craft epoxy resin. It is a doming resin and should layer nicely on your sticks. https://resinobsession.com/ItemPage/5857/Easycast–Clear-Casting-Epoxy-8-oz-kit-Restricted-Shipping.html

I would like to fill a ceramic or earthenware bezel with resin. Which resin would work with this (or would it work)? Would the interior of the bezel need to be glazed or unglazed? Many thanks! Kristina

Hi Katherine

I am using CR20 Polyester Casting Resin and adding a pigment paste to the mixture. I have used the 1% catylyst to the resin and also doubled it as it is only 150 ml tester mould. The mould was then put in a vacuum pot, air bubbles forced out. The results were interesting in both cases..the resin never really became solid…peeling off the brass pen tubes..!!

I then bought some pigment paste from the same supplier as the resin they manufactured. This time it still had not fully hardened under final turning on the lathe.. but was better than first two experiments..

Could the problem be the pigment paste causing problems with the setting agent.. as I use Pearlex Powders to enhance my casts adding pine cones for example ..no problems at all..

I read on your blog somewhere that this can happen with using pigment paste.. If it does can you use powders to alter colour of resin..and does it work as well forming a solid colour..ie Ultramarine??

Thank you

@Ziggy,

I don’t have any experience with that kind of polyester casting resin. My first thought is that there is too much moisture to allow the polyester resin to fully cure. Have you talked to the manufacturer? Since you’re using their resin and pigment paste, I would think they would have some good recommendations for you.

Yes, you can use powder colorants, but unfortunately, you can’t mix two powder colors to make a new color. If ultramarine is what you want, then you need to add a ultramarine powder.

@Kristina,

I would say most any epoxy resin would work for this project. How big is the vessel? I might make a specific choice based upon the volume of resin you need.

As for glazed or unglazed, glazed would be preferable if the unglazed pottery changes its look when it gets wet.

Excuse my but I ask my dad to buy me a v for vendatta mask that is made from resin but he refuses saying that resin is bad for your skin and those selling on ebay are for display only. What is he talking about and since all of v for vendatta are made from resin? Thanks.

Excuse my but I ask my dad to buy me a v for vendatta mask that is made from resin but he refuses saying that resin is bad for your skin and those selling on ebay are for display only. What is he talking about and since all of v for vendatta are made from resin? Thanks.

@Alan,

Once resin is mixed, it is inert and shouldn’t cause any problem to your skin unless you are extra sensitive to it.

Hello Katherine,

I’m looking for polyurethane doming resin but struggling to find a place to purchase. It will be poured over vinyl decal then mounted on a car. Due to the sun exposure, I believe polyurethane is the way to go. No yellowing, flexible & no cracking. Can you name some brands & online retailer. I tried Arts & Crafts places but only found Epoxy. Thank you

@Ignant,

Try the folks at smoothon.com. They have a large selection of polyurethane resins that should be able to meet your needs.

Hi Katherine, I’m wanting to make some cameo necklaces and was wondering if epoxy resin would be alright? I’m a newbie to anything like this I’ve never used it before. Thanks

@Chloe,

Yes, epoxy resin would work. You will need to do two pours: one for the ivory pegasus and one for the black background.

Hello, I am a thinking of using polyurethane for my first time, because i do not want yellowing or bubbles that may happen with epoxy. (from reading your thread) Plus I live in Idaho, very dry, but cold right now…if i open windows and fan would it be ok?

Also you say epoxy is best for beginners (me), will it turn out clear, glass like without bubbles if im just making simple objects like coasters and coffee bean jar lids, etc. Its so expensive and i dont want to buy the wrong one, lol. These will be items I will sell in my craft booth.

Thank you!!

@stacie,

You will need to follow the safety directions for the polyurethane you use. Some require respirators whereas others do not. (By the way, just because you can’t smell dangerous fumes doesn’t mean they are not there.) Since you’re a beginner, I will strongly suggest starting with an epoxy resin. The Resin Obsession super clear would be great for what you’re trying to accomplish. It casts super clear and bubbles are almost never a problem.

I’m thinking of making cabochons/decoden for a phone case and I am putting the resin in a mold. Should I use epoxy resin for this? And what brand would be good? And if I want it glossy should I purchase a glaze? Sorry for all the questions x

I am a newbie venturing into the world of resin(jewellery) & after a long search have stumbled on this site. Your answers seem so informative & knowledgeable, I was wondering if you could help me? I have decided to use epoxy resin as I am new to this aspect of craft & its properties seem to tick most of the boxes, however, I am worried that it may discolour, cause irritation to piercings (as it may come into direct contact with them) and ideally I would like to be able to waterproof the finished piece. Are there any varnishes/coatings that would allow the finished product to be hypoallergenic, waterproof & have long lasting colour/clarity? Thank you so much in advance, Kind regards, Hannah

@Katalina,

You will need a strong resin that will be somewhat impact resistant. I would suggest either the Resin Obsession super clear epoxy resin or the Alumilite Amazing casting polyurethane resin. As long as the mold for your case was produced with a shiny template, your casting should come out shiny as well.

I am planning on building a bar top for my Daiquiri Shop. I have purchased 8 foot bamboo poles that I want to lace together and then cast in Resin. I plan on building a large box mold out of melemine and adding my bamboo and then filling it. It will be over 1 inch thick, but the bamboo will fill most of the area. My question is, what type of resin do you recommend for a clear pour and that can be removed from the mold and is halfway durable. Also, do you have any experience cutting a fully cured cast? Can it be cut on a table saw? Thanks so much. Just found this website and have enjoyed your suggestions.

Thanks

@Hannah,

I don’t know of any coatings that would specifically make resin hypoallergenic, but if it has cured properly, it shouldn’t cause an allergy problem for the great majority of people. You may want to go with a jewelry quality resin, like the Resin Obsession super clear resin, which is designed for people to use for wearable jewelry.

Hi Katherine, I have learned so much just reading your answers to all the other questions–thank you!

I want to make pebble soap dishes, using just enough water proof resin to hold the pebbles together (i.e. I don’t plan to fully embed the pebbles in the resin, so water can drain through the pebbles.) What resin would be the best choice?

Thanks!

Hi Katherine,

I have a bunch of questions regarding EasyCast resin.Can you kindly help me? I am considering selling resin jewelry on Etsy. Can I sell EasyCast resin based jewelry on Etsy? Is EasyCast resin toxic after drying? I had followed a couple of your videos about epoxy resin and was highly motivated to make some.But in Germany, I did not get epoxy resin so I made some polyester resin jewelry, but it was too cumbersome so I dropped the idea, although they looked wonderful. I wanted to try an alternative, may be EasyCast. Please suggest.

Thank you,

Sumona.

@Sumona,

Yes, Easy Cast is safe once it’s cured and is good for jewelry.

Hey there! I have just started painting some abstract acrylic art & would like to put a high glass/shiny coat over the top-However, most of the colors that I am using are neutrals-So I can’t afford to risk the yellowing…What would you suggest that I use?

Hi Katherine 🙂

I haven’t started yet, but primarily interested in resin Pyramids. I ordered Easy Cast epoxy, but as I’m reading, I feel like it’s not going to set up in a larger mold? My molds are 3-4 inches at base.

Also, wanted to know how to layer them, to make chakras. I read that basic food coloring will work. How to do the layering? Would I need to wait 24 hours between each layer?? UGH. I don’t have a place where I could use poly resins. 🙁 I have some really great ideas, though. What is your advice on this?

Thank you so much for this site!

@Shannon, The Easy Cast should work fine, but don’t use food coloring. Resin doesn’t like water! To do the layers, you don’t have to wait until they are completely cured, just cured enough that the two layers won’t blend. Two to three hours between layers should be fine.

Hello! I make antler and bone jewelry. I am looking for a thick durable coating for my pendants. It needs to be crystal clear and shiny. I affix gemstones to the bone and antler cross sections and then cover them. So far I have used poly, but I don’t like how toxic it is and it takes a lot of layers to get even a thin coating. What would you suggest? Thanks in advance for your time and help!

Hi Katherine!

I work for a company that sells and makes their own body jewelry (ever see those kids with the big holes in their ears?) I follow your blog as a guideline, yet I can’t get my resin to come out clear. We make image plugs, which consist of either an acrylic or steel base. I then cut out an image and lay it into the blank and coat it in resin to give it a dome. I’m having trouble with bubbles and my resin not looking clear. I’m using Max 1618 Impregnating Resin. Is my resin the problem? Are there differences between the kind I’m using and regular resin? Any suggestions would be much appreciated. Thank you!

@Taylor, I’m not familiar with that resin. I would suggest contacting that manufacturer for tech support.

@Julie, does your project have ‘sides’ or not?

I am making art projects with pieces of broken glass and glass beads on canvas. What is the best type of epoxy resin to use to coat all the glass pieces and seal them into place? I want everything to be clear (no yellowing or bubbles).

thanks!

Hi Katherine

I’m wanting to experiment with pendants which would effectively be a thick silver bezel with a silver back. I want to pour the resin into the pendant cup half way, then set some shell into the half set resin and top it up with a resin top coat. The amounts I will need at a time will be very very small. On the same principle, can you mix sand with resin to give a rough appearance rather than a shiny one, and what would be the best type both these applications. Thank you for your help.

Sizzler

@Sizzler, you can add sand to resin, but it’s still going to finish with a glossy surface. You can see what I mean in this tutorial: https://resinobsession.com/Resin-Tutorials/248/Seashell-resin-jewelry-and-magnets.html If you want a matte surface, I would suggest going over the surface with a 600 or higher grit sandpaper.

Hi Katherine. I want to make a wood tea tray and embed sea glass, pebbles & pottery shards. Have never used resin and the posts I find related to this type of project are contradictory. The Easy Cast is limited to amount that can be poured, and the polyester types seem to need a respirator and special shop. Can you help me figure out what kind of resin to use? This will be a usable tray, not just a decorative one. Thank you for your help!

I am making a bottle cap epoxy table top. I used Parks Supr Glaze to start, but am finding that I need more than I originally thought. I have to cover the initial coatings with more epoxy to make it completly level and blemish free. Will it be OK if I switch to a different brand of clear coat epoxy for the next coat, or will the 2 different brands react badly together?

@Tom, It has been my experience that if you put ‘like’ on ‘like’, i.e. epoxy on epoxy, you will most likely be okay.

Hi I would like to pour resin inside a wooden vessel to make it watertight so that it can be used as a vase. I can build up layers or maybe pour some and turn the lathe on to spin the resin onto the inside walls if that will work.

Please kindly suggest the best product for this use,thank you.

@Robert, I’m sorry to say that resin isn’t suitable for what you would like to accomplish.

Oh hello!! I really hope you can help me! I’ve spent hours researching epoxies and still am not sure what will work best. I’m leaning toward Hardman Double-Bubble Green, but it doesn’t list “wood” which might be a problem. I am not a crafter, so I need a lot of help…

My 4-year-old daughter (now in heaven) fought cancer for 2.5 years and “earned” a glass bead for each and every procedure she went through. I want to display them on my wall, so I bought a window (the one that would flank a front door). I hot-glued each bead down on the wooden back, and eventually the glass top will sit over it. However, the glass beads come off with a little hand pressure, and I know a few will fall off when the project is upright on the wall (which is unacceptable). Someone told me to cover it with “liquid glass” or epoxy. This project means a great deal to me emotionally, so I can’t mess it up because I can’t go back and get 1265 beads.

So I need a CLEAR epoxy/resin/?/ that will hold little glass beads to a backing that is partially hot glue/partially wood. There ARE wood sides to the project. I don’t intend for the beads to be fully submerged, as there will be a glass window on top eventually. What would you recommend? Thank you very much! (feel free to email me if you’d like.)

I should also add, I’d like it to be a glossy finish, but because some of the beads will probably be sticking up through the epoxy/resin, sanding won’t be an option. (The beads are all different sizes). Again, thank you so much.

@Annabeth, I’m very sorry to hear that you have lost a child. That must be very hard for you. Instead of using resin, have you thought about just using a different adhesive for the beads? I would suggest our E6000 adhesive. https://shop.resinobsession.com/products/e-6000-jewelry-adhesive-glue-for-jewelry-findings It will hold better than the hot glue.

Hi Katherine, yes, I have thought about using a different glue. It would just require many hours to pull up each individual bead, pick off the glue beneath it, and reglue it. I should have just used a better glue to begin with. I was hoping to save time by just pouring something over them, but perhaps i just need to spend another 10 hours re-glueing.

Will that E6000 adhesive glue glass to wood? Just verifying!! Thank you for your help.

@Annabeth, yes E6000 will work for wood.

Hi Katherine,

I’m wanting to make resin castings for plugs for my ears as in body jewelry. I need to know if resin is too toxic to do this? Any suggestions would welcomed! 🙂

Thanks,

Venita

@Venita, Once the resin is cured, it is fine for it to come in contact with the skin.

Hi Katherine,I saw in a earlier post that you suggested Resin Obsession super clear epoxy resin or Alumilite Amazing Casting Polyurethane resin to make cabochons. Are any one of these resins harmful.

Do they have a strong odor.

@Keshia, Most epoxies don’t have a strong odor, but polyesters do. Some polyurethanes do as well.

@Keshia, I would suggest becoming familiar with the MSDS information on the resins you would like to use. Part of that information includes health and safety guidelines.

I have what may be a goofball question: I’m experimenting with casting for the first time to make Halloween decorations- specifically a lifesize skull that I want to add LEDs to to create a glowing effect. I’m new to casting and on a budget and the prices for resin were a bit of a shock. My question is can I use off the shelf Polyurethane (i.e. clear Minwax) to do this? I have a silicone mold that’s currently curing. Also due to volume of material to fill a large cast, I’m attenpting a mold within a mold- I sculpted a ‘brain’ that I’ll make a silicone mold of and insert inside the skull mold. My thought is that I’ll be using less fill volume (will be semi-hollow) and create a cool 3-D see thru effect. But back to the central question: Minwax is Polyurethane right, so can it be used to cast? I was also curious if the Castin’ Craft catalyst would improve curing the Minwax?

@Rob, Minwax is meant to be a coating (e.g. for a bartop). It’s not meant to be used in a mold. You should also only use catalyst designed for the specific resin. The Castin’ Craft catalyst would not work with the minwax resin.

I use an epoxy resin from Little Windows.com The reasin is easy to use and dries hard and clear like glass. Its by far the best I’ve seen for ease of use for beginners and those who are experienced. 🙂

@Patricia, We have a discussion on this in our forum: https://resinobsession.com/Resin-Jewelry-Making-Forum/5/How-can-I-……/Help-embedding-a-spider/125.html

Hi, I am interested in “preserving” a black widow spider in resin for a paperweight. I am a complete novice on this. It will probably be about 2 to 2 1/2 inches thick squared (or so). Which resin type would work for that? How do I go about “drying” the spider without the large part of it’s body shriveling up? Any info on this?I would really appreciate it! thanks, Pat

Hi Katherine, I’m a novice in resin and just as much a novice on the computer – i couldn’t figure out how to get to the forum?..I have watched some you tube videos??but specifically?.have not seen anything about spiders in resin??.I have read that the spider has to be dryed, but when that happens, the body shrivels up??any information you can pass along would be appreciated. Thanks,

@Pat, cut and paste the link from my post above into a new browser tab to get to the forum post.

Hi. I live on the Big Island of Hawaii and have found a product by fiberglasshawaii.com 2:1 clear epoxy resin. It is less than 50bucks at ACE hardware for the catalyst and a quart of the resin, so I thought I would give it a try. I plan on using it for making orgone. Any experience with this product?

@Rebecca, unfortunately, I don’t have any experience with that product.

I want to use resin pebble tile. I dont know how to use. I stay in goa and here the climate is too humid. Kindly suggest. I have pebbles where in i want to make a tile out of it.

@Anupama, You may want to use a space dehumidifier while you’re working to allow for better curing.

Hi Katherine! Thank you for your expertise and for sharing it with all of us! What a blessing and a gift! I am new to resin so I understand to use an epoxy. I have an old window. I want to create a 3d effect design by using random broken or cut pieces of glass onto the existing window frame. I’m not sure if I should first glue my pieces onto the window and then pour an epoxy resin over to coat, or if I should first pour my resin onto the window frame and then place my pieces of glass into the resin? Can you tell me your opinion and which resin would be best for this project? Many thanks to you!

@Starr, I would glue the pieces down first. Be sure to coat the back of the piece well with glue so that you have a good adhesion across the entire surface. Doing it the other way would probably still work, but there’s a greater risk of trapped bubbles rising up later in your resin.

Hi Katherine!!! You are fantastic and so informative :-)…thank you for you info and the answers to other peoples questions which where also helpful however I won’t to build a table top (no surface to start with) out of resin and mosaic tiles then later attaching it to a cast iron base…what resin do you recommend? How can I build the surface for it without the resin sticking to it (a box frame covered with wax paper)? How thick should I make it? Will I be able to smooth the edges after it cures? Many thanks for your time 😉

@Kathryn, since you’re pouring the resin into a mold, I would suggest our Resin Obsession super clear resin. The resin won’t stick to wax paper, but your box is going to get heavy. Make sure it has good support while curing. The thickness is your choice, but you will be able to sand it to smooth out any rough edges after it has cured.

I have attempted to use resin in small molds for jewelry. I used alumilite and it cured way too quickly as I barely was able to get it out of the cup after the instructed mixing time. Is there a resin with a longer working time? A few bubbles are not a big deal to me, but the little bit I was able to get out was filled with bubbles.

Hi Ms.K! I’m love your dye products! I purchase them from you all the time! I have a concern about epoxy resin. I have a online store and I make funky jewelry using different shaped resin molds. I like epoxy resin for all of the reason you’ve listed and I’ve been crafting with it for a year now. But I want to find a type of clear casting epoxy resin that will harden like glass. Is there such s thing as that? I mean my pieces come out nicely cured but I want something that will be rock hard and easy to work with that wont eat up my glitter and dye I put into it.

@AMH, have you tried the Resin Obsession super clear resin? It works great in molds, cures clear and very hard.

@RebeccaG, the Resin Obsession super clear resin is designed for molds and has a 30 minute working time. Bubbles are almost never a problem. It won’t cure as fast as the Alumilite resin you used, but it will be cured within 24 hours.

Hi, I am making a base( almost 2 1/2″ with resin to insert a cylindrical lamp and I have used FAMOWOOD. This is the second time I use it and perhaps it is clear like glass, it always become yellow as it is curing. I also used resin releaser this time, instead of oil like I was told and I bought it at Michaels. Any idea of why it becomes so yellow? and is it going to work to release this kind of material?

Thank you

@Heather, unfortunately, I’m not familiar with that brand of resin. Some resins will yellow with time, especially if it’s not one designed for resin jewelry and crafts. I would suggest contacting the manufacturer.

Katherine I have just painfully striped and painted 3 stacking tables. I used Americana Metalic paint. These tables will be used for guests to set plates and sweating drink glasses on. Would the Minwax be my best choice to coat table tops to prevent stains but not change the color? I have dozens of coasters but some friends and family just ignore them. Please help. Thank you, Kathy

Hi Kathy, I’m afraid I don’t have enough experience with wood stains and waxes to know whether or not this is a good choice.

Hi Katherine, thank you so much for that very clear and easy to understand explanation about the different types of resins. I was wondering if the epoxy resin would be the right product to use to make furniture appliqués in silicone molds? Also, I’ve seen that some of the appliqués that they sell on Ebay are made of resin and “wood fillers”. Do you know what type of wood filler can be safely mixed with resin? Can sawdust be mixed with epoxy resin for these appliqués?

Thank you!

@Linda, I would use a very hard curing epoxy or even a polyurethane resin. Unfortunately, I’m not familiar with wood fillers. Sawdust will take up ‘water stains’ when mixed with resin, unless it is sealed first.

Dear Katherine you seem to know a lot about resins. I want to make A5 paper sheet sized clear panels about 10mm thick with jewellery and other gubbins set in them. What would be best to use, I have never used resin before. Any help would be appreciated.

Thanks

Do you have a mold for your project or will you be using A5 paper sheet as your template?

Dear Katherine thanks for your reply. I intend to make a mould. Essentially a frame on a board lined with polythene and grease agent. Arrange items in frame and then pour over resin. What do you think?

Chris

Using a good mold release will help. Will you be able to take apart your mold box? Since you won’t be able to flex it, I wonder how you will get out your casting.

The polythene would lift off and that’s how I envisage removing plate. Gonna practice with it but what type of resin should I use.

Thanks

Chris

Hi Katherine – I am trying to embed objects in a large casting in a glass container, two layers with the object sitting on the 1st cured layer. I am using a Polyester Resin with a Catalyst but am having issues with the casting getting very hot and then discolouring from clear to a yellowish colour. Can you advise if this discolouring can be controlled along with the heat by reducing the Catalyst – does a larger casting need a lower amount of Catalyst? Thanks in advance!

@Richard, I’m afraid the yellowing is a normal occurrence with polyester resin, although I don’t usually see this right away. You might try adding less catalyst. The amount you need depends on the thickness of the casting.

@Sandy, I would think so, but can’t be absolutely sure since I’m not a chemist. I would suggest checking directly with your resin manufacturer to be positive.

Hi Katherine~I make replica foods for museums and historic houses, and have long used museum-safe materials like air-dry clays, papier mache, acrylic paints, etc., due to concerns about off-gassing and potential damage to period pieces. Having recently used polyurethane resins for an outdoor food display, I was relieved to see your comment that, once cured, resin is inert. I cast small fish in resin. Once thoroughly cured, they were sealed with an acrylic sealer; painted and shaded with acrylic paints; then given another final coat of acrylic sealer. Do you think encapsulating cast/cured resin pieces in museum-safe acrylic sealers should nullify curatorial concerns about off-gassing? Many thanks.

I’ve been using epoxy over wood tables but it doesn’t seem to get hard enough. I have an extremely large tree that I am planning to cut up horizontally into round stump cuts….where you can see all the rings….. and need the best, hardest, cheapest, product available to cover them. Any suggestions?

I am on facebook Kelly Palmer, {the Tamaha giant} in case you want to see pictures of what I am doing.

@Kelly, what resin have you been using?

Do you mind if I quote a couple of your posts as long as I prodvie credit and sources back to your site?My blog site is in the exact same area of interest as yours and my visitorswould genuinely benefit from some of the information youprodvie here. Please let me know if this ok with you.Regards!

Hi Katherine,

I’m using Easy Cast Clear Casting Epoxy, however I noticed that it has a slight yellow tinge to it. Would you have any recommendations for epoxy resins that dry completely colourless? Thanks!

@Apple, if you are pouring the resin into molds, I would suggest the Resin Obsession super clear resin. It dries crystal clear. No yellow!

Hi Katherine,

I started using Ice resin for my first resin projects.

I have made two rings in a silicone mould however, I embedded some string into it and some of the string is slightly sticking out and on the other one, the string has left the corner without some resin in it.

I am wondering can I add more resin to it once it has cured to cover up these pieces and then sand it back?

@Amy, that is certainly what I would try to attempt first.

I’m a complete novice but making a project for my son’s school auction. I need to set bottle caps in a pattern in a wood frame. What do you suggest? Thanks!

@Leslie, if you just want the bottle caps to be a decoration, I would suggest gluing them on instead of trying to set them in resin.

Hi Katherine,

So excited to find your blog!! It’s great you willing share your knowledge & experience so freely. THANK YOU x

I’m brand spanking new to the use of resin.

My project is to use fabric to cover a timber table then cover in resin to seal, protect & preserve the fabric.

Best adhesive adhere fabric to table & best clear resin to use on top please?

@Esi, here’s a discussion in our forum that should help: https://resinobsession.com/Resin-Jewelry-Making-Forum/5/How-can-I-……/Making-a-resin-tabletop/550.html

Hi Katherine, thanx a lot for your very informative article, Im gonna fill a big gap between two 1 metere long logs with resin, to form a table!!! What do you suggest؟! And i also have to mold it too.

Thanx for your helps.

@Michelle, If you are looking for an epoxy, then I would suggest using the Resin Obsession super clear resin. Otherwise, if you are experienced with resin, a polyester would be a good choice here as well.

Hi Katherine,

I will gladly use the Resin Obsession but is it still considered a soft resin like easycast? Even though my coasters look great I can’t see myself giving them or selling them to someone if the first time they use it it’s going to get indentations. Above there was mention of a resin sealer spray, do you think if I spray that on the coaster before the first use it will solve my problem and make it a harder dent free surface?

Hi everyone,

Katherine is the only person I have noticed to explain that easycast is a soft resin that if you try you can easily dent a cured piece with your fingernail. That being said I’m confused as to why most people say it is great for coasters. My coasters look amazing but once I set a glass on it it leaves dents. It’s got me very discouraged because I really like making them. But I don’t like that the dent. PLESE HELP!!!

Thanks Karherine I will give it a try…

@Michelle, the Resin Obsession super clear resin cures much harder than the Easy Cast epoxy resin. I have used it for coasters and have been very happy with the results. The resin gloss sealer spray will give you a final glossy finish, but won’t harden the resin.

Hey Katherine, I will be making a laptop desk made out of plywood. I will have pictures, paint, maybe some wood letters on the surface. It will have the weight of a laptop on quite often and I would like it to be very clear. What would be the best resin to use?

@Baylee, this blog post should help you make a decision: https://resinobsession.com/Resin-FAQ/406/Advice-on-what-resin-to-use.html

Hi Katherine I’m a beginner and would like to use resin to cover small wooden laser cut earrings, I would like a dome shape for the resin with limited application. What would be the best resin to use in this instance? Thank you

Dear Katherine,

I am a beginner! I would like to take jagged pieces of glass and embed them onto a framed window pane. Would you recommend that I first apply a light coat of epoxy and then embed my pieces of glass (hoping this will hold the pieces in place), allow to cure. Then finish window pane with final coat of epoxy? If you feel this is correct, can you share with me the best epoxy to use that will be easiest to use and will dry the clearest with no color. It will be hung will sunlight will be shining through! Thank you for your expertise!

Hi there, I am completely new to resin, I’m wanting to make some keyrings trapping photographs inside, how do i make a hole at the top of a rectangular peice for the split ring to go through? is there a special mold or do i drill?

Many thanks!!

@Starr and @Abby, this blog post should help you make a decision: https://resinobsession.com/Resin-FAQ/406/Advice-on-what-resin-to-use.html

@Lu, I would suggest drilling a hold in your finished casting.

hi there could please give me some advice on sealing porcleain and ceramics? I’m cutting up old cups and plates for jewellery and the cut pieces being porous are staining easily when worn . I had tried a crystal clear epoxy but found it too soft and tended to get dirty . Obviously I’m not using a mold and need more of a brush on sealant . Thanks heaps in advance 🙂

@Aimee, which brand of resin were you using?

Hi! I hand paint lazer cut shapes for earring making & I would like to know is there a resin I can use for glazing. I tried Mod Podge, but it doesn’t give me the thick glossy look I’m looking for. Also, if I pour the resin onto the earrings, how can I keep it from running over to the back of the earring? Thanks in advance!

Hi Katherine, it seems like your the wonder woman of resin and I couldn’t find any reference of people covering CD mosaics with resin so I thought I’d ask the resin guru 🙂

I’m covering a flat table with cut up cds and want a hard protective coating that is clear enough for the cd’s to catch the light in the same way. I tried just a spray varnish but this compromised the shine. The resin also needs to not interfere with the shiny coating as I have learnt grout can (this is my second attempt at this project, I only got up to the grout last time). I think I have narrowed it down to Enviro-tex lite pour on or easy clear cast epoxy but haven’t ruled out Hiflex EasyFlow 60 Polyurethane Liquid Plastic Casting Resin. So…

1) Which, if any would you recommend for a beginner and an under 1cm deep covering and

2) how would you recommend I go about making a mould around the edges to keep the resin in while it dries? (I read the above where you mentioned a doming resin however I have been unable to find any at a reasonable price) and

3) should I use grout with this or would none be better? I don’t mind either look so it’s whatever will work best. 🙂 thank you in advance!

@Ronette, for glazing your earrings, I would suggest either using a doming resin or using Judkins Diamond glaze. Here are two tutorials on our blog showing the two techniques: https://resinobsession.com/resin-tutorials/domino-resin-pendant-tutorial/ https://resinobsession.com/Resin-Tutorials/401/Glitter-keychain-tutorial.html

@Jasmine, I have answered your question in our resin forum: https://resinobsession.com/Resin-Jewelry-Making-Forum/5/How-can-I-……/Making-a-resin-table-with-CDs/1842.html

That’s brilliant, thank you so much!

Firehouse kitchen table made of stained plywood with a rounded edge, vinyl department patch adhered to top then coated with resin is the goal…the table is used hard with hot pots regularly set directly on it. Unsure how to treat the wood surface prior to resin as it has already been stained several times. Also unsure of the best adhesive to use for the vinyl decal on the wood prior to epoxy. And then trying to determine the best epoxy/resin. Huge project that we never dreamed would be this hard when it first started out. Your site is the most informative I have found anywhere. Help?!

@Di, I have answered your question in our forum: https://resinobsession.com/Resin-Jewelry-Making-Forum/5/How-can-I-……/Making-a-resin-table/1853.html

Hi Katherine,

I’m so glad I found your page. I hope you can help me with a problem…I have been using a two part epoxy called bio clear 810. I do pours of about 1/4 inch or more where I layer them and paint acrylic in between to create abstract paintings with depth. I have a crab coat that I pour on top as an ultra v protectant to prevent yellowing. I am however still not happy with the clarity. It tends to muddle the under paintings and still yellows a little. I do between 3 to 5 layers. In your experience what is the clearest product I could use for this? thank you so much for any advice you could give -Tracey

Hi Katherine,

So much thanks to you for running this forum, and sharing your expertise!

I carve jewelry, mostly rings, out of wood. I usually carve tiny settings in them and set semi precious stones using a glue adhesive epoxy. Some of the stones are probably very porous material, and some also break easily. I’m wondering if painting a layer or two of epoxy resin with a brush over these stones will give them a little more strength.

Also, can I do the same on the wood rings themselves?

And if I attach the coated stones to the coated wood while still wet, will they stick well enough to each other as to not fall apart? Or should I coat both with resin..let cure, and then just use epoxy glue to adhere them together? I have no experience with epoxy resin, and am a little worried that resin might interrupt the way that light catches the stones and crystals. Thank you for any advice you can give. Much appreciated!

Hello!

It’s so great to see someone who takes the time to respond to questions!

So as a beginner, I have a few questions. I’m making a large project in which I would like to use resin in three different parts. I’m making my mailbox.

In the first, I have cast iron number pieces that I would like to add colored resin to the inside with purple ink (they are like ivy and don’t have a solid middle and so by adding a colored middle it would make them easier to see). I would need it to dry hard, be uv resistant and have a transparancy.

The second, I am making my mailbox out of stained glass. I’d like to coat it in a doming, crystal clear uv proof, non scratching hard resin so as to protect it more.

And the third I saw online (as you may have) that one table that was made with photoluminescent glow powder poured I to the natural holes? Well I would like to take a wood board, carve my last name into it and pour the resin mix into that.

The big wuestions is if their is a resin I could use for all of these projects or if I would have to get different resins for each? And which polyurethane resin would you recommend? I plan to do these in my garage with the door open and during a dry day (I live in Pennsylvania).

Thanks so much!

You can paint the stones with epoxy, but in my opinion, I do think it will affect the light refraction of the stones. You can use the wet epoxy as a glue (or glue the wet parts together). It will adhere parts well.

Very useful info thankyou.

Would Epoxy Resin therefore be more suitable for bubble top decals for cars? or would the epoxy be too soft still once cured? I have some decals here and I think they are epoxy as they are quite flexible.

Also where should I be looking to purchase the right resin for doming automotive decals? any advice would be greatly appreciated. 🙂

@Michaelle, I don’t know of a doming resin that can withstand the outdoor elements well.

@Michaelle, for a project like this, I would refer you to the group at http://www.smooth-on.com. They have a larger selection of polyurethane resins that would be suitable for your project.

Thank you, I tried and contacted smooth-on after looking through their site but they said their products don’t dome and wouldn’t work for what I want to do. Thank you though! I’ll just keep looking:)

Hello, where I am at, many of the resin’s are unavailable such as the actual casting resin, the only resins I have access to are resins found in home depot, such as parks super gloss resin, or one of the quick setting epoxy resins that are mainly used for bonding, am I able to use the parks super gloss or the quick setting epoxy resin to make little beads/casts from molds? Or is the super gloss only good for “glossing”, and the quick set wouldn’t set right/ or get stuck to the silicon mold?

@Amy, I wouldn’t expect those resins to work well. They are meant to be used as adhesives and tend to mix very thick.

Hi Katherine I was wondering could you help I am doing an Art project I want to finish my canvas works with epoxy resin which I am finding hard to get at short notice.Would it be on to use polyester resin ?

@Cass, no, I would not recommend a polyester resin. The surface exposed to air remains sticky and would require sanding.

Hey Katherine,

I am looking to make a larger mold of a traditional water jug (half gallon) and want to fill the inside with nuts to make it look like the nuts suspended in water. That being said I want it to be as clear as possible just like water. Would you recommend a polyester resin or epoxy resin for this? Also since it is such a large object I am worried about cracking and how stable the resin will be once it fills the handle. Would you suggest pouring all at once or in layers to help minimize this? Any other tips you have for pouring larger molds please let me know! Thanks for your help!

@Shawn, With a casting that large, I would suggest going ‘inexpensive’. You are going to have challenges regardless of the resin you use. You will have to pour in layers because the amount of heat a casting that large and thick poured at once will be a lot. You may need to consider pressure or vacuum casting to make sure your casting(s) come out bubble free.

Hi Katherine,

I am looking to cast some paper sculptures, ranging from 10 cm by 10 cm to chair size, and wondered what the best and most economical way would be to do this. I wouldn’t mind it cracking and causing bubbles as it would give a more interesting effect and I can always recast to solidify the cracks I think. Starting with the 10 by 10 what would be the best way to make a cheap cube mold and the best epoxy or polyester Resin to use that is transparent and hard? Thanks 🙂

@Lizzy, I would suggest either building a box mold that fits your specification or casting a mold from silicone of a 10 cm cube. As for the best resin, use the Resin Obsession super clear resin. It casts very clear and hard and is specifically designed for molds. https://shop.resinobsession.com/products/super-clear-resin-12-oz-epoxy

I am looking to make 1″x1″ trinkets. I plan on painting them with acrylic paint so I assume I would use white resin? Which resin would be best if I need a hard and sturdy product? And what should I use to protect the paint from chipping from wear? Thanks so much!

Hi Katherine,

I have a fish skeleton that I would like to cast and frame to put on a wall. The skeleton is about 8 inches long and 4 inches tall and it’s about an inch in thickness. What would be the best product should I use so it doesn’t damage the bones? Or is this even possible? I appreciate your help! Thanks!

Hi Tina, do you have a frame to put the fish in? A casting that large is going to be heavy, so I’m wondering what you have for your frame. I can then make some suggestions.

Hi Katherine,

I bought a plastic box frame from the craft store that is 8″x10″. The problem with that is that I’m not sure if it’s deep enough. The fish is about 3/4″ thick and the box frame is only about an inch thick so that wouldn’t leave much room. I have another plastic box that I can cut the sides down so that it will be deep enough if I need to and it’s about the same dimensions, if that makes sense. I’m going to make the actual frame out of some barn wood.

Greetings! I am writing from Brasil to kindly ask for help: I am trying to make a marble dust surface finishing to cover the surface of an open air art sculpture made of concrete plates. The idea is to apply a thick layer of marble dust pre-mixed with epoxi resin, spreading it over the concrete plates surface, and once the resin is cured and dry, to grind it and polish. The tricky thing is that when i mix the marble dust with resin, the marble dust turns grey. I have been using titanium dioxide powder (white pigment) to make it white again, but i feel it comes out less natural then if i was able to preserve the marble dust natural color. I am making several tests trying to make the powder impermeable before mixing it with resin. My impression is that the reason the marble dust turns out darker (more grey than white) it´s because it gets ‘wet’-like, soaked in resin, just like beach sand turns darker when wet. Please help me figure this out, how can i preserve the white tone of the original marble dust when mixing it with resin? I am currently using 40 grain of marble dust mixed with a less thick powder like grain. the idea is that it will shine in the sun the most possible, without using the white pigment (titanium dioxide), preserving the white from the marble grain and dust when mixed with resin. Sorry for the long explanation and thank you tons in advance for the attention. Best, Marcello

Hi Marcello, yes, you are correct in that the dust is turning grey because it is getting wet. The best suggestion I can give you is to try a powder additive specifically designed for resin. We have several powder colorants in our shop that may be of help. https://shop.resinobsession.com/collections/colorants/powder Unfortunately, I don’t have a good way to help you keep the marble dust ‘dry’ enough so that it looks good when mixed with resin.

Hi Katherine, appreciate your reply.

I noticed writen where it described the diferences between types of resin, that the “Epoxy resin won’t withstand the heat produced by a polishing wheel and will turn cloudy on the surface”.

What if i use a wet poIisher, would that permit me to reach the high gloss with epoxy resin and marble dust? I was figuring the water would keep the temperature lower and not afect the resin..

Thanks!

best,

M.

I don’t know. I’ve only ever used a wet polisher when I’m making my own cabochons from minerals, stones and such. It would be worth a try, but make sure the resin is very hard and fully cured first. If you give it a try, let me know how it goes.

Could anyone please let me know if epoxy resin will turn yellow with time or UV exposure? I’m a beginner to resin and I have no idea about this. Besides, how many layers does a project require? I mean, is a project made of resin enough or does it always need a coating resin? Please help me.

Thank you so much

All resins will eventually yellow with UV light exposure. Some have additives to slow down this process so that it takes years instead of months. As for your project, one layer should do it. You shouldn’t need an extra coating unless you want it to be very shiny.

Hey there, hopefully you are still answering questions here!

I’d love to know what resin you would recommend for me to make things like this for my ears, http://i.imgur.com/9wxxg49.png

I will be pouring the resin into steel tunnels. I am hoping to be able to put lots of different things in the resin, like dried flowers, crushed opal shards, solvent resistant glitter, metals etc.

Thank you so much for your time 🙂

Provided you have a mold to pour them into, I would recommend the Resin Obsession super clear resin. https://shop.resinobsession.com/products/resin-obsession-super-clear-resin-for-jewelry It cures very hard and crystal clear.

Thank you!

Yeah, I will be pouring it into and leaving it inside of the steel eyelets so that it doesn’t touch any skin.

Katherine, you seem so full of knowledge on this subject that I can’t help but ask you about something I’m trying to work on! I’m a beginner with all of this and was wondering what would be the best epoxy to use to make a cake plate? I plan on putting candy throughout it and just want it to come out as clear and sturdy as possible! – Hope to hear back. I’d love your input! Thank you so much!

*I also have two different molds for it. One being silicone and the other is a thinner plastic

Hi Katheirne,

I’m a beginner when it comes with using resin and like any beginner I’ve been encountering so bumps along the way. I’m currently using the easy cast resin with silicon bangle molds. When I take the bangle out after 24hours the top is clear as glass but the sides are a frosted look. I like the look for some jewelry but would love to make an item that is like glass all around. What is your advice for making the whole product crystal clear?

Thank you 🙂

What template did you use to make your silicone bangle mold? The silicone will pick up the surface of your template. If the template had a frosty look, so will subsequent castings from a mold made from that template.

It seems like it’s the mold since the sides are not fully clear. Do you have a recommendation of what brand of mold I should use to get that glass look?

We have a couple of bracelet molds in our shop that are made from shiny templates. You can find them here: https://shop.resinobsession.com/collections/molds/bracelet

Hi katerine

Im trying to cast some pictures and pennies within a small panel door that has a recess of about 1ft x 2ft and a thickness of about 4-5 mm what would be a good water clear resin to use?

I did try using poly craft slow set polyurethane water clear casting resin but after it all going really well i left it to cure over night to find large raised bubbles had formed, i live in the UK so humidity is high so im guessing that was the cause also i wasnt sure if i need to do a sealant coat first of some sort (its fatory paint finished MDF)

Any advice would be appreciated

Thank you

Hi katherine, thank you

Do you have any advice for suspending photos in 5mm cast

I was thinking of doing a 3mm base layer then 2mm over the photo but im struggling to find definitive answers on how to go about it and i see you are definitely a resin guru, would the base layer need to fully cure so as to sick the photos down before the second layer?

They would only need to partially cure to the point that the photos wouldn’t sink.

I am making up a Sea Glass and Sea Shell grouping in a OLD Printers Tray. The backing on the tray is fiberboard and I want to fill each section with some beach pebbles. I would like to know what you think would be the best way to adhere them to each section…..glue them in individually …use resin or what would you suggest?

I would probably glue them in. The resin is going to seep through the fiberboard and make it look waterstained in those areas.

I’m making fairy wings that are thin, I’ve made them with epoxy resin and they are flexible. I want hard wings that don’t bend that are clear but where i can add pigments if i want. what should i use?

I’m not sure I understand what you are wanting to accomplish. Can you post your request along with a sketch or picture of what you want to make in our forum? https://resinobsession.com/forums

Hi Katherine,

Great website! Do you think this would work on brass

porch lights? I don’t have a porch so they really take a

beating.

I heard that the latest thing to protect brass is acrylic

urethane… but I like the idea that resin is so thick. Is this a

crazy idea or do you think it would hold up okay under the weather and very hot Texas summers?

Really appreciate any advice!

Nicole

You would need to use a resin designed for outdoor use. An industrial marine resin would be my choice for a project like this.

Thanks for answering! I need to do something right away and will check into marine resins.

Hi

I hope someone can help me . I make inlay and I used deyed wood to my project.. now I want use black polyster resin or proxy on my project. I want to know does polyster resin or proxy effect on dyed wood . disapper the stain from woood If I use polyster resin on my project ?

thanks

I wouldn’t expect it to change the dyed effect of the wood, but I am concerned whether or not the wood treatment would affect the resin’s ability to stick to it.

Hello, I have an acrylic container in which I am displaying sand samples from all over the world. Each compartment of the container holds about 2 cups volume, and each compartment is about 2/3 full of sand. I would like to add clear resin to the top to ‘seal’ the sand in each compartment to prevent so I won’t have spillage or mixing of the sands. I think I’ll need about 2.5×2.5×1 inch volume of resin to top off each compartment. What would you suggest? I’m a newbie and not really prone to detail work….but if need be, I can employ my meticulous engineering husband to the task.

Hi Beth, any resin that is good for molds should work. The resin chart on this blog post should help: https://resinobsession.com/resin-frequently-asked-questions/resin-casting/

Thank you! I’m glad you can see that several options might work. Sounds like I have a project coming up 🙂

Good morning. Can i use easy cast epoxy resin at the bottom of a coffee cup? Will it be safe to drink from? I want to draw a picture and have it be seen at the bottom of the cup when you need a refill. ;).

Thanks!

The manufacturer has not tested the resin at that temperature. Unfortunately, they cannot recommend it for that purpose.

How is it best to put pinecones in resin?

HI Sara, I would suggest dipping it in resin and allowing it to cure first. That will seal any air in or out. Once it is cured, use it as you would any other inclusion in your resin.

I want to make resin covered leaf ornaments and bowls but I’m not sure what resin to use. Where I live is dry and cold in the winter but humid in the summer and I currently don’t have a work space (Except my balcony) as I’m in an apartment. Any recommendations?

Are these going to be for indoor and/or outdoor use?

Indoor. For like jewelry bowls or fruit bowls or something (not for eating from) but more decorative.

I’ve also never worked with resin before

That’s great! Thanks for your help 🙂

Help! I was trying to buff a gloss onto a 1 1/2″ circle of resin. I was just given a dremel mototool. When I put the cloth circle to the resin it immediately scraped a large scuff onto the top of the piece! Can it be buffed out with sandpaper? Or would coating it with more resin help? I’m a newbie and I’m lost!

Hi Renee, sorry to hear you are having problems. How big is the scuff? The reason I ask is that recoating with another layer of resin would be easiest, but if the scuff is coarse, the resin won’t completely mask the scratch. Instead of looking smooth and glossy, it will look a little frosted underneath. Without seeing your scratch, I would try to sand it down, finishing with (at least) a 1000 grit paper or higher. Then, you can recover with resin.

Hi! I am making jewelry and it seems like the polyester resin is reacting with the metal jewelry bezel and turning some of the edges green. Is there any way to prevent this? I am also finding that it doesn’t fully set and the smell is horrible. Any other suggestions for a resin that sets clear and quickly that won’t react with metal?

An epoxy resin would work much better. There is a link to a chart on this blog post that helps to explain the resins we sell and which one is best for your project: https://resinobsession.com/resin-frequently-asked-questions/resin-casting/

I want to fill a hollow 2 in. diameter glass sphere. The glass sphere does have an opening to allow for me to pour fluids into it. From what I’ve read on this page, it seems like the polyester would be the best. I’m worried that when it cures, the polyester will pull away from the glass sphere. I need something that will fill the space with a clear finish and not contract as it cures. Thoughts? Thank you!

Hi Alex, based upon your comment, I think an epoxy would probably be better. Why were you considering a polyester resin?

Miss katherine, how nice of you to respond to all these questions for so many years. Its obvious your very appreciated. My question has to do with large scale epoxy table casting molds, if not already asked prior. I noticed an italian company called Nucleo Studios that cast these solid beautiful epoxy tables with wood boards dipped into set up as legs. They call it wood fossil. Im going to attempt this art but id like to avoid costly mistakes. Now I noticed you mentioned epoxy cures soft in a large thick scale. Should i use polyester resin? An would it be wise to cast these 3in thick resin slabs in acrylic made molds with a release? What are good large scale mold making materials that epoxy nor poly will stick too after cure?

If I were going to attempt this project, yes, I would use a polyester resin. If you were going to try casting them in an acrylic sided mold, you would definitely need to use mold release. Resin will stick to acrylic. Once cured, the epoxy and polyester resin shouldn’t stick to silicone.

Thank you for the reassurance and not saying its impossible. Im going for it. I do know big companies have access to autoclavs an all types of advance equipment to cast large composites. I wanna find the limit of what one person can do from home without the fancy machines and without creating a chemical melt down disaster in ones garge. Ill check up.

Sounds like an adventure! Let me know how it works out.