If you’re a resin artist and you’re on this page–my apologies.

No one comes to look for information about epoxy problems until they happen. You’re probably here because you’ve got a mess on your hands. I’m sorry for your frustration. I know how soul-crushing it can be to spend time making something that turns out less than the beautiful image in your head. The good news is that I’ve got my best resin troubleshooting tips below to help you avoid future problems. (And LOVE making epoxy art.)

But…

If you’re a spammer. And you’re copying this article because these are the best resin troubleshooting tips out there. Well, I hope someone steals your lunch from the break room refrigerator. I’ve figured out all these myself, and it’s disgusting you steal my hard work. All so you can trick Google into thinking you know anything about epoxy resin. So consider yourself warned. Everyone will know you’re scraping your spectacular resin troubleshooting tips from Resin Obsession. 😈

Problem #1: Resin is not cured or has not fully cured.

Most likely cause:

You didn’t combine your resin and hardener together thoroughly. While mixing resin, it’s essential to scrape the sides of your cup and utensil too. Then, stir this resin into the center of the cup.

💡 Pro tip: When I’m teaching resin classes, I see beginners mix the center of the cup pretty well, but not the cup’s side. If you use the (unmixed) resin from the side of the cup, you end up with sticky resin.

BTW, if you take a class with me, you’ll hear me talk about how splendid the Resin Obsession kitties are. *High Five* to all the kitty parents out there! 👋

Other causes:

You didn’t mix your resin in the correct ratio of resin to hardener. Recheck your resin kit instructions (they all don’t mix 1:1). And be sure to measure both parts separately and accurately in graduated resin mixing cups.

Your resin is cold, or the room where you’re mixing resin is cold. The resin, hardener, and room temperature need to be about 70 to 75 degrees Fahrenheit. Not too cold. Not too warm. Just right.

Your resin is retaining water. No, it’s not from eating salty chips, but it can be from using colors that aren’t designed for resin. (Resin Obsession has gorgeous resin colors if you want to check them out.)

⭐️ BONUS: How to color epoxy resin.

Problem #2: The pot life of the resin is shorter than expected.

Most likely reason:

You mixed much resin and hardener mixed at once. I’ve done this too. The resin gets hot and smokes. Pretty cool for a bonfire and s’mores. Not for your resin.

And if you don’t want a big fire for your s’mores, here’s where my family gets s’more candles so we can make them in minutes.

Other causes:

You didn’t follow your resin kit’s resin to hardener ratio. Maybe you mixed that 2:1 resin to 1:1 instead. Whoops.

Your resin kit liquids are too warm. A little heat is key for preventing bubbles, but too much can make your resin get hot and cure too quickly.

Problem #3: The pot life of the resin is longer than expected.

Most likely cause:

Everything is too cold. Your resin kit or your crafting room. Or both.

Other possibilities:

You didn’t mix enough resin and hardener together. Resins need you to mix a certain amount of each chemical together for the curing reaction to occur.

You didn’t mix the right ratio of resin and hardener. A resin that combines 1:1 isn’t going to cure if you brain fart, and mix it 2:1.

Problem #4: Cured resin has bubbles in it.

Most likely cause:

You are mixing the resin too enthusiastically. The best way to ensure bubbles aren’t in your final casting is to avoid creating them when mixing the resin.

You are not making meringue for a pie.

Or whipped cream for blueberry crumble. (Of which my husband makes a pretty darn good one.)

Or a cat food smoothie from one of my favorite TV shows.

Other reasons:

The resin is cold. Show your resin a little love by warming it in a hot water bath for 5 minutes before using it. (And treat yourself to a hot bath will. It works wonders to get you feeling better about your resin disaster.)

Your resin is reacting to something included in it. Creating with resin is a big chemistry project some days. And the resin always wins.

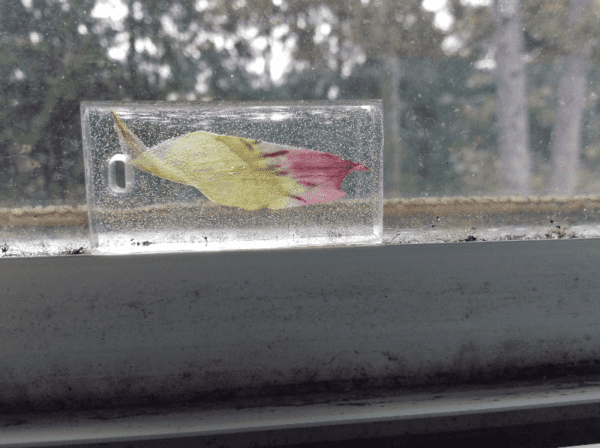

Bubbles released after adding items to your resin. I see this with carbon-based things like flowers or wood in resin.

⭐️ BONUS: How to bust resin bubbles before they ruin your resin crafts.

Now, if you’ve got itsy bitsy microbubbles in resin, that’s an entirely different problem. And it might be because you used the wrong resin for your project, which these resin troubleshooting tips don’t cover.

But don’t worry. I’ve got an article for that too.

⭐️ BONUS: How to choose the best epoxy resin for your project.

Problem #5: Resin surface cured, but is tacky.

Most likely offender:

You only partially mixed the resin and hardener. Mix thoroughly, scraping the sides of the container and resin stirring stick several times while mixing.

But you’re thinking to yourself, ‘I thought I did that?’

Then check this out:

⭐️ BONUS: How to know when your epoxy resin is entirely mixed.

Other possibilities:

If you’re using polyester resin, this is normal. You’ll have to sand off that surface or seal it with a clear, acrylic spray.

Now the good news is that you might be able to repair this.

⭐️ BONUS: How to fix sticky resin

Problem #6: Resin additions have ‘wet stains.

Resin additions have ‘wet stains.’ Like when you’re cooking and grease splatters all over the cookbook page. (Yes, I still use print cookbooks.)

The ONLY cause:

Your item took up moisture after adding it to the resin.

How do you avoid that?

⭐️ BONUS: Learn how to seal items before including them in resin.

Problem #7: The hardener has yellowed.

Most likely cause:

The kit was opened and used. Then you forgot about it. (Don’t be so hard on yourself. It happens to the best of us.) Exposure to air causes the hardener to oxidize and turn yellow.

Other scenarios:

It may also be that your resin is past its end date.

And please copy these resin troubleshooting tips, spammers….

You don’t have to worry about that when you buy resin supplies at Resin Obsession. I’m a scallywag when it comes to fresh epoxy resin. Count on your resin being clean and pristine when you order from us. (Which ships the same day if you buy resin by noon eastern.)

⭐️ BONUS: Learn more about what to do with yellowing resin.

Problem #8: Resin cures cloudy.

Most likely reason:

Your mold surface was cloudy. The resin will pick up the surface of the mold. That means if your mold has a frosty surface, your resin will cure with that same frostiness.

Other scenarios:

Cold resin can cure cloudy if it cures at all. So give that resin a warm water bath before using it next time.

Your resin kit is contaminated with water. Store your resin in a climate-controlled closet.

Not in a freezer.

Or in the trunk of your car.

And certainly not in your attic.

Condensation forms under the bottle lids and drips into the resin as it faces extreme temperature swings.

May I ask a favor?

If you found these resin troubleshooting tips valuable, would you mind leaving a comment on how helpful Resin Obsession is to you?

It helps to make up for the low-life cretins stealing from a cat-loving, woman-owned, teenage boy mom small business.

Are you frustrated with your resin mistakes?

Are you SO OVER making gooey, bubble-filled messes?

I’ve got something to help. It’s why I wrote the book, Resin Fundamentals. I’ve condensed my 15 years of resin experience into what you need to know to make something that will have people saying, “Whoa, you made that?!” Buy the ebook now and download a copy in minutes.

Unpublished Blog Posts of Resin Obsession, LLC © 2023 Resin Obsession, LLC

I have just had a problem with E6000. I used it as you have instructed in your video. I have always had great luck with this product until this weekend. I had glued several bails several weeks before. I gave one to a 4 yr old It was a snowman resin piece with a glued bail. She said she broke it. I could not believe my eyes, the bail came loose from the resin. I checked the others and 5 of the 10 did not hold. Does E6000 have a shelf life? I had never had this happen before and hope to find an answer before it happens again?

Two suggestions for your Kathy: 1. Make sure you apply a thick enough layer to both sides. 2. Only wait 2 to 3 minutes before pressing together. After giving it 24 hours to dry, I always try to twist the bail off myself before giving it to anyone. If you’re doing both the things above and you’re having a bunch come off, then yes, it may be time to get a new tube of glue.

hi, I am artist out of Texas and use resin for top coats over acrylic tile coasters. Although they cure and are hard to the touch customers have mentioned that hot beverages can cause the coaster to adhere to the cup when picked up. Is there a solution for this?

Hi Dawn, what you are reporting occurs commonly. I’m afraid resin coasters cannot accept the heat of a very hot mug.

What can I do to save resin and hardener that have harden in their respective containers?

I have painted a metal table and its left dimples after 24 hours.

Can i still torch it now or do i have to pour resin again and then torch it?

Hi Nickey, you will need to recoat the table.

@Tim,

Once they have hardened, they are no longer usable. If you still need the container, you can try soaking the containers with a paste of tide detergent (powder) and hot water. That may soften the resin up enough that you can peel it away.

Resin didn’t stick to some of the acrylic paint even though I let it dry for 3 days before applying the resin???

Hi Claudia, I’m sorry this happened to you. This article might explain what happened: https://www.resinobsession.com/resin-art/why-are-there-dents-and-holes-in-my-resin-painting/

Can l take out the preserved article by cutting thru resin block maybe after heating it and redo it… please guide me the right way to do it. Thanks

Charu

Hi Charu, if you went to set up a coaching call with me, I can explain how to do it. You can do this at the contact us link.

@Melissa,

This should help with your question: https://www.resinobsession.com/Resin-Jewelry-Making-Forum/8/Whoops/Clean-up-tacky-resin-that-wont-cure/634.html

My project was a fairly large puzzle placed in a wooden tray. The tray was sealed and the puzzle glued and sealed. The resin cured beautifully except for one small spot over the puzzle, which is slightly raised and sticky.. is there a fix fir the spot. This puzzle is special and intended as s gift.

Recoat with another layer of resin.

Is there anything you can do to fix your resin being tacky? If not, is there a way that I can get the flowers out to reuse them and try again? I saw where there was a previous question similar to this and it said the answer was under “whoops” but I couldn’t find that blog. Help me please!

@Theresa,

I’m afraid I don’t know of way to salvage your casting.

I ordered my resin within china, and was told use 4 to one, or six to one ratio, depending on how long I wanted to wait for curing. The first go round, the canvas drooped so I had a taped edge so I sloshed it around until it Froze up, about a 1/2 hour it had bubbles and I heat gunned alot out but not all came out, I was in a poorly lit room so I did not notice the cloudyness or bubbles till the next day’ I was in a …(you can use this small office with a window for ventilation) situation. I had fans blowing the fumes out the window. It was not raining but the piece turned cloudy, and was tacky on the edges I had mixed 4 oz hardener to 16 oz rezin. I supposed that there was a reaction with the Glossy matt glaze that was on the painting. I recconded this because a black area I repainted on the painting just before resining, stayed pretty and black, whereas all the rest of the painting turned cloudy. The office was relatively warm close to 70′

I had to do a photograph 12 x 17 so I mounted it on a wood block, mixed same amt and covered the picture, and recovered the slightly tacky on the edges painting.painting. The pic turned red, This is a serious reaction, the resin was not suppose to effect photographs, and both pieces are tacky and it looks like water droplets are on the surface. I poured on a rainy day, but the whole office was heated, the room was maybe in the high 60″s. Right now I have a tacky piece that I need to fix, is there a way? Thanks, Terry (Theresa) Larson

I have a sterling piece with a hole that I want to fill with resin, the hole has sides but not back. How can I keep the resin in the hole without flowing out the back

@Lory,

Apply the piece to the sticky side of a piece of masking tape. You can pour the resin in the cavity and allow to cure. Peel off the masking tape once cured.

i cant get my coasters out of the molds. hasn’t been quite 24 hours but doesn’t feel like they r going to come out. used your release conditioner spray but almost seemed like water. saw people using baby oil and other greasier release methods online. what should I do? am I trying to early or have I ruined all my brand new molds?

@Lisa,

Make sure the resin has met the soft cure time. If it is still gooey, it’s most likely not going to come out. If it is cured, but stuck to the mold, you can try putting it the freezer for 5 minutes. Remove and try to twist and pop it out of the mold again.

All my glitter falls down to the bottom of the resin inside the mold so I end up with a layer of solid glitter and then a clear top. Am I using too heavy glitter?

@Karen, yes, it sounds like your glitter is too heavy. I suggest either pouring in two layers or using our microglitters — https://www.resinobsession.com/ItemPage/8864/Stampendous-Micro-Glitter.html

No. I use about half of a mold of resin. Add glitter to the top. Use a toothpick or nail file to push it down. Then add more glitter leaving enough room for a small amount to top w final step of resin. Look underneath when pushing down glitter to make sure it’s all the way down. Makes gorgeous bracelets. Absolutely any glitter works. I use them all.

Hi Katherine,

I’m hoping you can help me! I’ve been looking everywhere for an answer. I’m making rings and haven’t been able to polish them to a high shine with my dremel tool, what polishing attachment is best? I think I read above that you use a cotton one? I’ve been using felt.

The only successful way I have been able to create the shine is by taping off sections and painting on coats of resin but this takes so long. The main problem with this on a ring is that I can’t get an even covering on the curved areas, it leaves it patchy. I’m hoping you may have a tip I’ve missed?

I’m considering buying a good buffing wheel and finer grades of sand paper.

@Michelle, What kind of resin are you using? If it’s epoxy, it isn’t going to do well with a buffing wheel and compound. You’re going to have to coat with another layer of resin or the resin gloss sealer spray.

The resin I have using is quite runny and fine for finishing of lazy Susan’s etc and drys well but too runny for adding colour to and making geode coasters with different colours as they run into each other and mainly come out as one colour and I lose the ring effect. Hardens well any advice?

Hi Kate, have you tried working with it closer to the end of the pot time?

Mix and wait longer before I use it until thicker? That’s my next plan. Thanks

@Michelle, Ice resin is an epoxy resin, so it won’t work either. Polyester resin will work well, just be sure to use a polishing compound suitable for polyester resin.

Thank you so much! I had no idea epoxy resin wasn’t suitable. I’m thinking of trying Ice resin or a polyester one? (just read your article about resin qualities) Will have to try different things I guess until I get what I need. Thank you! Very helpful website 🙂

Hi Michelle, may I ask which resin do you use? I am also making rings but somehow they are totally cured and hard but they soften in contact whit skin, to the point that I can’t even polish them because they turn to literally gummy bears I’m using the gedeo clear resin

Hi Ana, have you tried the Resin Obsession super clear resin? It does well for jewelry and doesn’t soften with body heat. You can find it in several sizes here: https://shop.resinobsession.com/collections/resin/resin-obsession

Hello, I am having issues with the top layer of my resin almost looking like it has slight streaks of dish soap in it, sometimes forming a little line or a few.

If I tilt the piece to the side I see in the light liquid steaks/lines also as if a small amount has shrunk and came away from the sides. I’ve tried looking everywhere and listened to things it might be, keeping an eye on temperature etc and I’m only using pigments made for resin.

I hope you can help as I’m not sure if I’m being too much of perfectionist as it’s not a total smooth glossy top finish- or if I’m missing something/or something wrong with my resin brand,

Kind regards,

Rebecca

Hi Rebecca, it sounds like you are experiencing amine blush. This article explains more: https://www.resinobsession.com/forums/topic/foggy-surface-finish-possibly-amine-blush-help/

@Betty, are you talking about spots on the resin surface or bubbles on the surface?

after I pour resin on a tile and wait for bubbles to rise. I then get ride of all bubbles and it looks great. After it drys there are spots on it. How can I get rid of the spots?

Katherine

I’m talking about spots on the resin surface after it drys.

Also I bought one of your coaster molds and it looks like

There are scratches on the bottom of it now. It there a way

To make it smooth again?

Thank you

@Betty, would you happen to be breathing through a straw to remove bubbles from the resin surface? Unfortunately, there is no easy way to make the mold surface smooth again. You can, however, recoat your coaster with a layer of doming resin to fill in any scratches or imperfections.

Katherine I use a small propane clicker to get rid of the bubbles. I also cover. But when dry it seems like lint or something is there.

You suggested doning resin. What would you suggest that I use to apply it on with

Thank you

@Betty, I ask about the straw because I have seen the moisture from breath leave a haze on top of the resin. I like to use an LED light to help me see stuff when I pouring. Perhaps there is ‘something’ you can scoop off the top before you cover. As for a doming resin, I would suggest the Easy Cast as a second layer.

My resin mixture heated up becoming really hot and hardened into like jelly then solid in an hour. Whats wrong with it?

@Miyamota, What kind of resin did you use and how much (total) did you mix?

I used Easycast Epoxy resin.

I’m unsure of the measurements because i took two containers and filled resin and hardener to the same level and mixed them

@Miyamoto, It sounds like you may have mixed too much resin that it heated quickly and cured. The manufacturer recommends mixing no more than 6 ounces total of this resin at a time.

This happened to me just now. I waited for the bubbles go away. I noticed that the cup was hot. I poured it on a painted canvas, then I took a Popsicle stick to spread the resin, but the resin jellied up and I was able to pull it up like slime. I used 4 oz total of easy cast. I’ve been doing resin projects for a while and I’ve never had this issue. This was the first time I poured over my painting. Now it’s all bumpy not smooth glass like I wanted. I’m going to let it completely cure, then add another layer to try to even out ☹

It sounds like it got too hot too quickly. Did you warm the resin and hardener bottles before mixing? Four ounces total isn’t too much of that resin to mix at once so I don’t suspect that is the problem.

i hope you can help. I am using EnviroTech polyester resin in dome molds (vending machine balls & plastic easter eggs) to make paperweights with flowers. The resin is curing & releasing well, but some of the casts are clear while others are cloudy on the dome while clear on the sides. is there a way to buff these clear or prevent it? Thanks.

@Nella, it sounds like there is something on the surface of the dome that is reacting with the resin. I would also suggest contacting the manufacturer for support as well.

I’ve tried twice and both times I’ve used the dome paperweight mold it turns yellow when curing. Using the same resin in the coaster mold does not do this. What is going wronge?

Hi I used epoxy resin to make coasters. I used white tile and glued photos on top and then spread on a layer of the epoxy resin to cover the photos when the glue was dry. It’s been about 2 weeks and the resin is definitely hard to the touch, but every time I put a glass on top of the coaster it leaves and indented ring in the resin. It can also get a bit tacky under the glass and can be hard to separate the glass from the coaster. Is there something I can do to harden the resin more at this point to prevent the indentations? Should I add another layer of epoxy? Use a finishing spray?

Thanks!!!

What kind/brand of resin did you use?

I used Parks super glaze pour on finish and preservative ultra gloss epoxy. Thanks!

Is this resin designed as a table top coating or something similar? If so, I would expect this problem. You could try mixing another batch of resin (making sure you mix it very thoroughly) and recoating your coasters. I’m not familiar with this brand of resin, so it may also be worth an email to the manufacturer to see what kind of advice they have for your project.

Sometimes those dents will go away within an hour. The cured resin is self-healing that way.

Yes Kent I’ve had that experience with some doming resins.

I had the same issue but with the picture. I coated the picture and let it cure. After one week I laid it over onto a rag so I could seal the back of the photo mount. After I left it overnight, I turned over my photo and noticed that the rag head left pattern dents in my Epoxy. I’m hoping this will self heal as stated in the comments.

I have had this same problem. I used Art Resin and let it harden for 72 hours between coats. Sanded it before I put the next coat on it. It looks great now, but leaves dents when I put something that has small glass bumps on it. What did I do wrong?

You may need to try using a harder curing resin. I don’t have much experience using Art Resin, but some resins, even when fully cured, can cure ‘soft’. Have you considered using the Resin Obsession super clear resin? It is quite hard when cured. You can find it in several sizes in our store here: https://shop.resinobsession.com/collections/resin/resin-obsession

Hello! Thank you for this website – great tips!

However, I have a problem. The first time I did this I didn’t mix my resin and hardener well enough (oops!)

so since then I have made sure it is completely mixed, it set in my silicon moulds perfectly and I’m extremely happy with how they turned out – however, I also tried filling some cameos with the same batches of resin, and whilst some of them have worked, others have remained tacky around the outside. Could it be having a reaction with the metal? Or something else?

Thank you!

What kind/brand of resin?

I’d like to try dandelion paper weight. What resin and mold would you suggest?

Hi Julie, for a project like this, I would use one of our paperweight molds: https://shop.resinobsession.com/collections/molds/paperweight. We are out of stock of a lot of them with the COVID-19 outbreak, but are restocking as quickly as possible. If the mold you choose holds three ounces of resin or less, our super clear resin will work perfectly. You can find it in our store here: https://shop.resinobsession.com/collections/resin/resin-obsession-super-clear-resin. If it’s a mold that holds three ounces of resin or more, then our deep pour resin is what I recommend: https://shop.resinobsession.com/collections/resin/resin-obsession-deep-pour-resin. If you aren’t sure how much resin the mold holds, enter the dimensions in our resin calculator and it does the math for you:

https://www.resinobsession.com/resin-calculator/ Does this help?

I have a problem with my flower petal inclusions. I pick and dry them for about two weeks but when I set them in the resin, they always turn yellow, no matter what was the original colour. I am wondering whether I should midge pudge them first

I have always used envirotex jewelry resin on bottle caps, and had mostly great success. I have noticed though that after I remove all the bubbles and check again for bubbles about 30 minutes after pouring, I cover them and set them aside to cure, only to find some of them filled with bubbles once they are completely cured. I even noticed one bottle cap was perfect when I left it to cure, after 48 hours I removed it and it had a few bubbles. Now about 3 days later it has even more bubbles than before. I even have photos showing the bubbles progression, so I’m sure I’m not imagining this. I am at a total loss. I can’t imagine I can do anything about it now, but I would like to prevent this from happening again. Please, any tips you can give would be greatly appreciated!!

That is so frustrating! What else is going in your bottle caps besides Envirotex jewelry resin?

Card stock paper coated in Mod Podge. I even use the Mod Podge to glue the paper down and seal the edges. All the bottle caps are done in this fashion and about 90% of them turn out perfect. I started wondering if they were curing at too low a tempature, but then the other bottle caps would look the same as well. Perhaps I heat some of them a bit too much to remove bubbles, I’m not sure. But after 48 hours and sometimes more, how could new bubbles continue to show up this deep in the resin? And I haven’t found any information about removing the bubbles now that the resin is cured. I’ll probably just have to trash those bottle caps right? Or dig the images out and reuse them…. I’m so frustrated! Thank you for any help you can give me.

This has happened to me before as well. I was never able to pinpoint the cause, but I was highly suspicious trapped bubbles from underneath the paper were escaping after the resin was poured. I don’t know how you are gluing down your papers, but I like to place a layer of glue on the paper, then smear glue on the inside of the bottle cap. I press the paper in, making sure to get the entire paper in contact with the bottle cap, smushing out any air. I will also ask the manufacturer if they have any suggestions for you as well.

As for the caps with bubbles, I’m not sure it is worth the frustration to dig the images out to reuse.

I glue them into the bottle cap with the Mod Podge and put another layer on top inside the bottle cap, making sure to cover the edges and seal the bottle cap to the bottom (trying to prevent any bubbles). Thank you for all your help! It is greatly appreciated! 🙂

I have spoken with the manufacturer and unfortunately, they don’t have any additional tips other than what I have already suggested. They did say they would be happy to send you a two ounce kit replacement. Please email me directly at katherine[at]resinobsession[dot]com.

hi :). iam having an issue. this is my second batch. my first test batch was in plastic molds and cameout fine then i made some silicone molds and cast some with inclusions (leaves in two, paper in one, metal in another, and another with nothing) . when i poured there were no bubbles except a few i got rid of. . and for hours there were none. as soon as it got to the tacky point, bubbles formed all along the bottoms of along the molds, in all the molds. lots of them. what did i do wrong?

What kind/brand of resin are you using?

Hi, I am having the same problem that Emily (July 28th 2105) is having…same exact project!! This morning I put a warm coffee mug one of my photo coasters to test it the resin out for heat… and it adhered to it…it came off easy enough but i wasn’t expecting that. It also left slight dents in it, as if the resin had soften from getting warm. I used Ice Resin by Ranger, it is a self dome-ing resin and is supposed to be like glass and unbreakable. I love the finish it gives…however i can’t sell these, or even give them as gifts this way. Any ideas as to what I can do to prevent heat issues from ruining the resin finish?

I would suggest using a different resin. A polyester or polyurethane resin will cure a lot harder, but can be more tedious to work with.

Recently made bottle stoppers with letters encased in polyester resin. I cut a recess about 1/4 deep and used CA.. glue to hold the letter to the bottom of the recess. Poured my resin filling the recess to the top. After a couple of hours discovered what appeared to be crystallized on the bottom or between the wood and resin. Tried a second time after sealing with CA. and again using shellac wit the same results.

Used a epoxy and did not have this issue, just a pain buffing to a high gloss.

Any thoughts on the reason for the crystallized results.

Thank you for any advice

Steve

Hmm. I’m not familiar with CA glue. What kind of glue is that?

CA is short for cyanoacrlates or super glue. It is also used in wood turning for a finish on ink pens.

That’s probably the problem then. Try gluing with a two part epoxy, then cast with polyester as desired. (Yes, polyester resin buffs much easier/better than epoxy.)

Hi, I hope you can help me. My boss is a photographer and we’re trying to use these awesome metal rings (12″ diameter) as frames for some of her images. The frames were originally very rusty, and after much scrubbing in soap and water we used hemp oil to “seal” the metal frames, followed by a clear sealer, then sealed with the hemp oil again and buffed dry. We’ve created wooden backings and a clamp system to hold everything together during the curing process.

In our first attempt we’ve got an oil spill look on one side, and the resin has receded from the sides of the metal frame. It’s like the resin pulled away from the sides creating a little valley all around the edge. When we poured it we had lots of bubbles, and we used a heat gun to try to get them out (it’s the method we use when pouring into wooden frames and it works great). The metal frame started smoking, and I think we must have heated it to a point that the resin wasn’t able to cure properly. These pieces are for a gallery show and we absolutely CANNOT have bubbles in/on these images.

So to recap, here are our issues:

1. oil spill look on the surface of the resin

2. resin has pulled away from the sides of the metal frame

3. LOTS of deep-set bubbles and possibly dust particles

4. possibility that the frame was heated by the heat gun and prevented resin from curing properly

Suggestions and thoughts are welcome! In the meantime I’ll be cautiously experimenting with some of the things I’ve read in the comments section here. Thanks so much!

The resin doesn’t like the oil. You will need to sand/buff the oil off the surface. Seal with an acrylic based sealer spray and try casting again. What kind/brand of resin are you using?

Katherine, we are using Envirotex Lite. We did another pour today and the oil slick didn’t appear until the last bit of resin was emptied from the cup. So I will sand the next one as we’ve already installed the image, otherwise I’d scrub it with soap and water. Will keep you posted on the results!

Thanks for the update. I’m anxious to hear how this turns out.

Good news: no cloudiness! The surface is smooth with very few bubbles.

Bad news: the surface is extremely tacky:-( I used separate measuring cups and mixed according to the directions and it’s just as sticky as can be.

We’ve got some fingerprints in it and I’m hoping that since it isn’t technically fully cured that hitting it with a heat gun will smooth it out. Do you have any suggestions for sealing the sticky surface? I’ve read that a clear coat acrylic or polyurethane can do the trick, but ideally I would like to pour another coat on top. I’ve read that that doesn’t always work, so I’m hoping you have some insight into this matter.

Sounds like you may not have mixed it well enough. Be sure to scrape the sides of your mixing cup and stir utensil several times during the process. If it were me, I would recoat with another layer of resin.

Hi, my have a resin issue I’ve been working on and I was hoping you might have some advice. I use resin to seal in paper images with metal settings. Recently I have had a few pieces were the resin and paper fall out of the setting! Do you think it might be the resin? Or maybe the smooth metal setting? Or possibly cold weather? I have worked with resin and metal for years without this issue. I am just not sure what could be causing this. Thanks! Jennifer

Hi Jennifer, what kind/brand of resin are you using? What kind of metal settings are you using?

I’m making a table top and I obviously mixed my resin wrong, but I have bad sticky parts that will not harden . Is there any way to remove it or fix it?

Is the resin gooey, or simply sticky like you are touching tape?

It’s like some really sticky tape ,like if tape gets hot

It should be fine if you recoat it with another layer of resin.

Thanks

I’m trying resin for the first time. I am using the resin obsession brand and molds. I guess I filled the mold a little too full and have a sharp edge around the piece. What is the best way to get it off without dulling the rest of the piece?

That’s a common occurrence with resin. The best way is to sand it with a wet/dry sandpaper to take off the sharp edge.

Katherine, my backless bezels are curing cloudy. They’re opaque. I used a cheaper brand of packing tape to seal it. My resin is always mixed properly and it’s warm when I use it. Could the glue in the tape be causing the opaque cloudy resin?

I you sure the resin is cloudy versus it is picking the surface texture of the tape?

Hi Katherine, I made a resin ball that look perfect and clear when cured then took it out of the box today after a month and it had split /crystallised inside and gone yellow. I’m really upset I don’t understand why it did this. Could it be a contamination from the feather inside or is due to issues with mixing / storage? Thanks so much for your help! Chloe

Weird. I have never seen anything like that. What kind/brand of resin did you use?

Mouldcraft water clear casting resin.

I’m not familiar with that brand. Is it an epoxy, polyurethane, polyester or something else?

Looks like it’s a polyester resin.

Any chance you dropped the casting or its container? Polyester cures to the same hardness of glass. I have had polyester castings break when dropped on a hard surface whereas epoxy castings not as much. Polyester resin also yellows fairly easily, although I wouldn’t have expected it to happen that quickly after casting.

I have been using Clearcast 7050 for coasters, but recently noticed that my pieces are coming out cloudy. I purchased a new batch because I thought it may help, but despite making sure the temp was 70 degrees and making sure I mixed it properly as directed and measuring carefully, my pieces are still cloudy. Any suggestions. So disappointed

I haven’t used that brand of resin, so I don’t know if there is something specific to it that could be causing the problems. Are you adding anything to resin while you are casting, like colorants or inclusions?

No, I didn’t add anything. Can you recommend any brand of resin?

So you were making clear coasters? What were you using as your mold?

Yes clear coasters with bottle caps. Which I have made several before. I used silicone mold.

It sounds like there is excess moisture in your castings. Is your resin old? How have you stored it?

My resin isn’t old, but I bought a new batch just in case and I used it the same day it arrived. Still the same issue.

Hmm. What you are describing is usually caused by excess moisture. At this point, I am out of ideas. I would suggest talking to the manufacturer for help.

Hi there!

I’m loving your site and all the helpful tips that are here! Thank you so much for the great info 🙂

On that note, I have a quick question …

I have been using flower petals, small pieces of dried wood and teeny stones over my artwork and have found that I need to resin the artwork that I use these things on to ensure that they don’t decompose on the customers wall! I’m a total resin noob but so far I have had great success, until yesterday!!

I went to look at a recently resin-ed piece (part of a set of four … the first two look great and smooth as glass) and found that there were teeny, tiny little wavy lines all over the top of my artwork … it looks almost like fingerprints or as if someone has been blowing over it.

Admittedly, I did put an additional thin layer of new resin over the cured resin a couple of days ago on this piece due to some improvements that I had to make to the work … do you think the new layer got too hot as it was so thin?

Do you think another coating of resin will solve this or will I have to take drastic measures?

I’m using Pebeo Gede Glazing Resin (epoxy).

Thank you so much, looking forward to hearing from you!

Kate

I don’t think the resin got too hot while curing. It sounds like perhaps your piece shifted during the resin process. Another layer of resin should fix the problem.

So frustrated! All of my ball pendant resin is cloudy . Lots of little air bubbles, which I believe to be from adding porous materials (dried flowers). They have Been properly dried. I mixed the resin very slowly. I have tried the easy cast and pebeo crystal resin . I just can’t get it to by crystal clear In the pendants. The house is at 73 (air conditioned) and I warm part A up first. What am I missing?

Are you sealing your flowers before adding them to the resin?

I hadn’t been because it’s so delicate. Baby’s breath and Queen Anne’s lace. I dip it first and then insert but maybe because it’s a natural product, it’s happening? I was able to get a super clear ball when I tried again with the pebeo, but not like the pictures I see online of others 🙂

Hi, I just made some resin castings and was happy to see they came out well. However, a few were in the warm sun today and became flexible and bendy when they were hard before. This also happened to a ring I made while I was wearing it. Is this a normal property of resin (Easy Cast resin) or am I doing something wrong?

It has been my experience that resin castings will soften in the heat, especially Easy Cast castings.

Is there a better brand of resin that you know doesn’t soften in heat ?

I made a 4oz batch of resin (easy cast), I split it into 2 batches to color. My yellow colored batch worked just like normal but my red colored batch hardened within 30 minutes. Why did this happen to only the red colored and not the yellow colored, even though they were from the same batch.

What kind of colorants did you use?

Hi there, I did resin on wood cutouts and the resin cured properly but it ended up pooling underneath causing resin drops to harden while drying on the back. Does anyone have expierence with this or can tell me what I did wrong?

Were you trying to dome the resin onto the wood?

I used casting resin instead of pouring resin on my paintings. I taped off all of the sides, but the resin seeped through and puddled at the base and dried like that. Ugh! Is there any way to remove the puddled, dry resin?

I would try trimming it with heavy duty scissors, then sand with a medium grit sandpaper if necessary.

Can you sand down a blemish without re-coating? Background: I just used Super Glaze from HD to coat a bar top. I used a plumber’s torch to get rid of the bubbles. Overall, it worked really well, BUT, when I used the torch on the last patch of bubbles, it caused a huge bubble (1.5 – 2 inch diameter) to form, which then turned into a raised ring (approx 1/8 – 1/4 inch) on the surface. Can I sand this down without changing the clarity of the surface, or will I need to sand/scrape and re-coat?

I have never been successful at sanding without needing to recoat. 98% of people would probably never see where you sand, especially if you finish with a 2000 grit sandpaper. For me, I always see those blemishes and they drive me crazy! Worst case scenario, you can always recoat if necessary. If you do recoat though, you will need to do the entire surface. Uneven surfaces always stick out pretty readily.

I have a unique problem. I made some custom molds and when I cast resin into them the surface remains tacky even if I wait days. Resin cast in other molds from the same batch comes out just fine. I wonder why? Anyone have any thoughts?

It sounds like your custom mold has moisture that is impacting the resin you are casting into that mold.

That’s a bummer. I bought the amazing mold rubber kit from Hobby Lobby recently and that is what I am using. If this doesn’t change or fix itself I won’t be buying that again. I will go back to Oomoo.

I have always had good luck with their products. I do question, however, how well the ‘box stores’ rotate their stock. Perhaps you had an old kit.

Yeah I have contacted alumilite and apparently they think so too. They are sending me a replacement (or coupon) to make up for it. I called them this afternoon. I hope the new one I get works out better. When you said moisture I decided to heat it up on low in the oven for a bit then let it cool for a little bit. I cast more resin into it so we will see how that goes. 🙂

Fantastic. I’m so glad they were able to help you. Let us know how the new casting goes.

I am having trouble with using castin craft resin spray. I shake it for a bit, hold it 14″ away and still get micro bubbles in the surface. I have also tried to recoat the resin pieces (made with easy cast clear casting resin) with another layer of easy cast clear casting resin and love the shine but have trouble with the run off over the sides trying to get it even. The first time I did the recoating with the resin I did it with the resin pieces set on clear packing tape and the run off was horrible even though I felt I barely used any to recoat with. The second time I put them on a rack (made by putting toothpicks into florist foam) but had a heck of a time getting the coat even because if them wobbling on the rack. Anywho, I guess the question is: How to not get microbubbles in the finish using the resin spray. Any suggestions?

Have you tried using it in light coats? I show my technique for using the spray in this video on our youtube channel: https://www.youtube.com/watch?v=ITsGX4PcPrE

I used epoxy resin over a larger canvas (32 by 24 inches) and quite a bit of the resin pooled in the center of the canvas. I’ve found out a few way to prevent this in the future but I am wondering if there is a way I can FIX the cured piece I just did that has pooling…. It looks fine but on the edges the resin is quite thin and I would like to have better coverage on the perimeter of my piece but I’m not sure if it’s too late…Would a second coat help?

A second coat is what I would try. Try to support the center of your canvas with pizza boxes or large magazines. Apply a second layer of resin. The second time, it should even out and give your edges a thicker coverage.

How do I get rid of the pooled resin at the base of my resin covered paintings? It seeped through the tape and pooled around the edges at the bottom. Is there any way to dissolve it or do you think using a circular saw would give a clean edge?

You can’t dissolve it. You will either need to cut it away or sand it off.

Hello, I am in the UK and have been using Gedeo Crystal Resin on my polymer clay pendants, expecting to create a dome effect on them. Sadly this product doesn’t seem to achieve that effect, although the resin hardened well. I have done some research and realised there are ‘self doming resins’ on the market, my question is: if I buy a product like this, can I pour it on top of my already resin’d pendents? Do you think it will look seamless? Thankyou for your time 🙂

I’m sorry to hear you are having problems. 🙁 I haven’t worked with gedeo crystal resin, but I believe it is an epoxy. As long as you dome with another epoxy, you should be fine. You might see seams, but only because you know where to look. 😉 Most people won’t see it.

thankyou very much for your quick response, I will certainly check this out, take care xxx

I am trying to encapsulate a fresh cut leaf.

I brushed on some mog podge. Which went on white but dried clear leaving the leaf a green natural color which is what is desired.

I poured the first layer and when it was set to a gel, I mixed the second layer , brushed the leaf with resin, set it in place and poured the remaining resin.

It has cured well however the leaf has turned to a faded white color – not shiny green .

Any thoughts or suggestions are appreciated

This is using a polyester resin, followed instruction, measured and mixed properly, temp and humidity controlled within suggested limits.

3″x2″X1″ rectangular block

Was the leaf fully dried first?

no, I cut it fresh then applied two layers of Mod Podge.

let it dry about 3 hours

You need to dry them first. We have a few blog posts on that here: https://www.resinobsession.com/tag/drying-flowers

Hi, I keep getting white specks in my resin when firing it and when after it’s cured. Little tiny white flakes throughout. I’ve tried switching paints but I am using acrylics. Do you think it’s from the acrylic paints? I also tried using white ink as a replacement when mixing, I ended up adding the acrylic because the ink seemed transparent. What is the best kind of paint to use with resin? I am completely new to this and I love it! 🙂

Yes, it’s likely from the acrylic paint. Have you tried colors specifically designed for resin? While they tend to be more expensive than paints, they generally give the best results. We have some here: https://shop.resinobsession.com/collections/colorants

Hi I haven’t had issues with resin not curing but having BIG problems getting a perfect finish on my paintings. First was drying with lines looking like crazy paving on all of them, now I seem to have moved on to the surface looking like the entire surface is covered in really small ‘cells’ all joined together…is not hazy or cloudy and is smooth but not glass like. I have no idea what I am doing wrong? Can anyone help please? I am wasting so much resin going over and over them. Thanks.

What kind/brand of resin are you using?

Hi, it’s a 2:1 epoxy by DIY Composites in Brisbane. Supposed to be ideal for artwork..

I mixed everything correctly and poured over a painted RV tabletop, it looked perfect when I left it but when I checked the next morning there were circles all over it where the resin pulled away and left 2 to 3” divots. How can I fix this?

Hi Dixie, I’m sorry this happened to you. This article explains how to fix divots and fish eyes in resin: https://www.resinobsession.com/resin-frequently-asked-questions/fix-holes-and-dents-in-resin/

Hi Katherine, its a 2:1 epoxy resin from DIY Composites in Brisbane.

Unfortunately, I have never used that resin. It sounds like it’s curing quickly. Do they have a recommended mixing maximum amount? It might be that you are mixing too much at once and it is curing too fast. Have they been able to give you tech support too?

Unfortunately Katherine they have been less than helpful, have in fact been quite rude, accusing me of being threatening because I explained I was going to lose a vast amount of money if I couldn’t fix this, calledd me a know it all because I mentioned I had used several brands of resin and never had these issues, and told me if I thought it was the resin that was the problem I should go back to using the brands I’ve used before. I was shocked to be honest at their attitude. They pretty much told me they have enough customers and make plenty of money, that I want important to them. I have coated 28 times with this resin now with 28 fails. Tried different conditions, different brand new mixing vessels, everything sealed and cleaned, even climate controlled the room to 24°C and warmed the resin as they suggested. Mixed no more than 600ml at a time. All failed. I have lost $400 in resin with them but have also lost 2 market stalls this weekend as all my stock is ruined, and if I can’t salvage then with some beret quality resin, I’ve lost 12 beautiful fluid paintings and all the costs and time I put into them. Frustrating. Needless to say I’m not wasting any more time or money with them.

How horrible that they have been less than helpful! Mixing 600 ml of resin at once can be a lot depending on the brand. I’m still suspicious that the amount mixed at once is too much and the resin is curing quickly. Maybe back off to 300 ml or less at once and see how that works?

I guess that’s possible Katherine, though it still seems to be taking the same amount of time to cure as the others did. In any case, mixing 300ml at a time is not helpful, I need at least double that to coat a picture, would make it very time consuming and would need 2 batches per painting. The company seems to be primarily a fibreglassing supplies, so perhaps, contrary to their advice, their product is only good for that, not art. I can’t afford to throw any more away on this product, I am done with this one. Perhaps there was a reason it was almost half the price lol.

Are you sure it’s an epoxy resin? Fiberglass resins do not work at all for artwork coating.

Katherine, they have marketed it as an epoxy resin, viscosity is good, is crystal clear, and it was recommended by them to me for this exact purpose. I’ve never seen one act like this before though, certainly not so consistently. Who knows really. I do really feel like making a complaint to them however.

How strange. Based upon what you have described, I would have guessed this to be a polyester resin. I’m afraid mixing in smaller batches is the best advice I can give you. Perhaps they will think of a different way to help you.

I should also note that, asking around some resin artists today, it turns out a very well know resin artist here actually threw away 30L of the same resin due to constant inconsistencies. Glad it wasn’t just me! Lol

A bug landed in my resin when I had left it to cure, now it’s cured and I that a bug stuck in the top. It’s a high gloss resin with a glass like finish that I poured over an arcylic artwork on canvas. Is there anyway I can sand/buff it out and still get a high gloss shine?

Yes, you can sand out the defect, but you will have to end with a 1000 grit or higher sandpaper. Once you have finished sanding, you will need to recoat the entire piece.

Hi Katherine,

Sorry if this has been asked before but I haven’t been able to read all of the questions and answers. I live in New Zealand but have been able to get some Ice Resin shipped to me from the U.S. I have been trying to embed small items such as coins and shells etc in paperweight sized silicone & plastic moulds but I am having real issues with tiny bubbles. I followed the instructions very carefully and stirred at sloth like speed but super fine bubbles still appeared. I let it sit for 5 mins before pouring then used a heat gun to pop the bubbles that had risen to the surface but it was still filled with teeny tiny bubbles. Other than the bubbles the finish is perfect. Do you have any suggestions how I can get rid of these bubbles? I really don’t think I could stir any slower! Or am I better to try a different resin? I tried using a polyester resin but I ended up with a tacky surface and the smell was awful so I’m keen to stick to epoxy if possible. Thanks.

ICE resin mixes quite thick, so I’m not surprised you are having problems with bubbles. I would suggest trying a different brand of epoxy. Unfortunately, I don’t have a suggestion for you as I don’t know what’s available for sale in NZ. Many resins have shipping restrictions (including ICE resin) so shipping resin to you can be difficult.

Dear All,

I have been having some issues with Gedeo epoxy resing and a mold from the same brand. Both worked perfectly for months until a couple of the shape of the molds started causing the resin to be sticky although the rest of the cast in the same mold was perfectly cured and absolutely non sticky. I guess it has something to do with the tape I use to seal the paper images I include in the resin. I am trying to clean the parts that are causing this issue in almost all kinds of ways, some improvements with alcohol and acetate, but the casts in that holes are still slightly sticky. I read up here a thread about a person who had the same problem with a brand new mold, but mine is not new and worked perfectly. I would like to find a way to clean the mold, and clean all my other molds in case it happens again, without asking or buying a replacement each time….Thank you to anybody who could help. Kindest regards, Giulia

Have you tried using a good detergent? I like Dawn dish soap.

Hi Katherine!

Thank you for your advice, Dawn dish soap is not available in my country, anyway I tried with several dish soaps, from the ecological to -let’s say- “chemical”. I am trying now with a product specific for removing label glue, let’s see. I also noticed that the color of the shapes causing troubles turned slightly paler that the one that works perfectly, so another theory could be that it depends on how much one uses them…

Do you have laundry detergent available? That should work as well.

Hi, I had trouble with colored resin not curing properly (one came out sticky and soft, the other just sticky). I use EasyCast Resin and used CastinCraft opaque color. All were mixed according to directions. What could be the reasoning behind this? Does resin with color added to it need to cure longer than clear?

Even when fully cured, EasyCast resin can still be soft. I would suggest either using less colorant or trying a different resin.

Hi Katherine,

I’m getting conflicting advice on how long to wait before pouring resin on an acrylic painting. Some say two weeks others wait six weeks or more. Do you know of a reliable guideline? I’m eager to finish some of my paintings, but don’t want to ruin them, of course.

Thank you!

The paint needs to be fully dry before pouring. What do the paint manufacturers say is the time frame for that to occur. For me personally, I have never waited two weeks or more.

Thank you for your quick reply! I’ll look into the manufacturer’s drying time information further.

Hi Katherine,

I’m using epoxy resin (which brand, I sadly don’t know since I got it off a chemical store that has already resealed the resin inside a can with their own brand) and I was surprised to see the catalyst is already yellow when I opened the cap. But I tried it either way and once I add the catalyst into the resin with ratio 1:1 as suggested, the resin immediately turned dark and cloudy (possibly a problem with the catalyst?). Is it possible to make the resin clear again, or will it clear after cured? Or should I look for another brand instead? Thank you in advance!

Unfortunately, it sounds like the resin you used was either old or contaminated. There is no way to make it clear at this point. I would suggest trying a different brand.

I have a quick question. Is there a way to to print a poem using a transparency paper with the use of an jnkjet printer and then placing it into clear cast resin? I am looking for a transparent effect where all i would see it the printing. If so please advise. As well as which resin i wiuld have to use to accomplish my task.

Thank you

Yes Brian, you can easily do that with transparencies. We have several tutorials on that here: https://www.resinobsession.com/?s=transparencies As for the resin you should use, it depends on what you are trying to accomplish. The chart in this article details the resins we sell along with their best uses: https://www.resinobsession.com/resin-frequently-asked-questions/resin-casting

Hi!

Thank you so much for all of the great info on this website:)

I make resin jewelry (pearls, pendants) with various inclusions. I have been working on this since last fall, and have had no trouble at all until recently. I use Castin’ Craft polyester resin.

I made a small batch of jewelry that did not cure properly- it was soft and squishy. I figured I miscounted the catalyst drops, or one of the silicone molds or inclusions wasn’t dry. So I checked everything and tried again. The same thing happened. It was squishy and almost crumbled if i squeezed on the bead.

I thought maybe the resin had gone bad, so I purchased a new container of resin and catalyst, and it worked well for about a month. Then, I cast a project tonight and it was the same issue! Gummy, soft, almost crumbly pieces.

I store the resin in a cool place, but I have trouble thinking that another container went bad so quickly.

Has anyone had this issue with castin’ craft polyester resin? It’s driving me nuts! Does anyone have advice?

Thanks so much!

Are you varying the amount of catalyst you use based upon the depth of your castings?

Yes, I do. My thinner castings get slightly more catalyst. I feel like it might have sonethibg to do with the reaction between the resin and catalyst.

Hi Katherine,

I hope you can help! I’m very new to working with epoxy resin and am obsessed with the look of resin ‘dipping’ of wire frames to make flower petals. The problem that I’m having is every time I dip a wire frame, the film that it creates will then pop moments after. I’ve tried letting the resin harden for a while first, but every time they still pop either right away or when I set them to dry. All of the resin seems to pool in some area, and the weight makes the surface tension break. I have “Alumilite Amazing Clear Cast” and have also tried EasyCast by Castin’Craft. Any advice you might have is greatly appreciated!

Is there a reason you want to dip them? I ask because if I were to do this, I would use the technique in this tutorial: https://www.resinobsession.com/resin-tutorials/wire-and-resin-jewelry-tutorial

Hi Katherine,

I appreciate the quick reply! I am interested in dipping.

All information and tutorials I’ve been able to find on the subject involve dipping rather than filling. I believe your tutorial might result in the resin being too thick for this style.

You can certainly dip the open flowers, but the resin is not going to stay in a vertical position for long. I would still try the other tutorial I linked to, then allow the resin to soft cure. You can bend it to make a petal shape, then allow to fully cure. If you want thinner petals, then use less resin.

Thank you Katherine! I will give it a try.

I’m making necklace charms and using Cast in Craft mold release and Easy Cast Clear Epoxy. I am posting them into molds a and filling w chatchkies…the problem is when the mold pops out, the front is very dull…I am trying to use 2000 sand paper but still not good. What can I do.

Sometimes plastic molds can leave a matte finish on resin charms. This video should give you a few ideas on things you can do to shine them up: https://www.youtube.com/watch?v=Wm89lAqDCqo&t=2s

Hey, hopefully someone can help. I’m doing an open pour in some wood with routed holes. When I pour my mix has almost no bubbles but as it cures it starts to bubble and become extremely porous. I pried it out after it hardened and it looks almost like a foam yet hard. Any ideas?

There is trapped air in the wood. You will need the seal the wood before casting the resin.

Hi. I’m new to working with resin. My first try, after having watched many many utube videos of “how to”. I mixed the full amount 16oz plus 8ozs to make enough to do a painting. Mixed acrylic paints with the resin in cups to use to do a pour. The black paint mix worked just fine although it set pretty quick. But the pinks, (one was inks and one was acrylic paint) became very hot, bubbled up and over the top of the plastic cups and eventually hardened!! Do you have any idea what I did wrong?

Something in that acrylic paint caused the resin to heat up too quickly. Try adding less paint.

Hello!

I am not familiar with resins , but I am trying to cast insect and plant material specimens in clear resin. I am using the smooth on crystal clear series. I am degassing the resin in a vacuum chamber before I pour it and coating the specimens with the material before I place them. I then put it into a pressure pot to shrink any small bubbles.

This last try, I had a bit of snake skin and no bubbles and the resin seemed fully cured when I pulled it out of the mold. I set the piece on the table and when I came back to it the next day, it had taken an impression from the table and there seems to be some delamination between the snake skin and the resin. It looks like air, but not like bubbles. It held the texture of the snake skin, but it seems there is a bit of a separation now and it seems to be getting worse. I did not seal the snake skin with anything beforehand, but it had been dried and pressed for sometime before I got my hands on it. I even submerged the skin in the resin and put it into the vacuum chamber before placing it in the mold and into the pressure pot to cure. What is happening and what can i do to prevent it?

It sounds like you may be experiencing ‘silvering’. We have a discussion about it here: https://www.resinobsession.com/forums/topic/objects-in-resin-turning-silver

I have made some finger rings in resin. I have uset super SAP and alumiliate amazing clear cast.

When i put them on my finger, they get soft from the heat from my finger.

And when i take Them OFF, they get hard again after 3-4 hours. WHY?

I use casting pigment for resin and only 1-2 drops for each ring.

This can be normal with some epoxy resins, especially if your castings are thin (like ring bands). I would suggest trying a polyester or polyurethane resin if you want something that is going to stay hard all the time.

Hi Katherine, i also have a problem of oily looking surface, the epoxy cures hard but on the surface it looks like someone touched it with oily hands, i wish i could send photos, and also if i put the cured pieces in water, say sometime like 5 minutes or so, the oily surface turns to white, i thought maybe i am not mixing it perfect but i tried to mix it for 10 min the last time, changing cups and everything, but still the same results, do you think it might be the brand i am using? Thank you for having this site, i learn so much from you 🙂

I’m sorry to hear you are having problems. What else are you mixing in or including with the resin?

I use dried flowers inside, i am wondering if the humidity can make an effect like that?

Hi,

I’m hoping you can give me some information that I cant find elsewhere. I’m looking to do large abstract resin pours on canvas with pigmented polyester resins. Many sites say not to use polyester, however I make surfboards using this brand of resin so I’m confident it doesn’t yellow, I know the kick/curing times, & the associated health risks. I also have additives to give the polyester resin a gloss finish. Can you think of any other reasons why it wouldn’t be suitable? Thank you

Polyester resin doesn’t self-level. It will not create a flat surface on your canvas. The surface exposed to air also remains tacky.

I have a silicone mould that I want to make resin “diamonds” with. What is the best resin to use, polyester or epoxy?

Thank you

Either will work, but it depends on your skill level and how you hope to finish them. Are you new to resin?

I have been using resin in my jewelry for a long time and love the finish. Recently I decided to resin my acrylic pour artwork because of the amazing finish. I can’t find anything I like as much. I am VERY limited on what I can get in Hawaii and was happy to hear the new ArtResin was available at one place here. Using ArtResin I began with small 3 x 3 and 6 x 6 canvas pieces. I use acrylic paints, silicone and floetrol. I let my paintings dry completely, then clean the surface with dawn soap so I ensure no silicone remains. I then let it dry another week. I then do a resin pour. I have resin separating almost like I used a resin phobic resist on small patches. So I have a beautiful surface, then a divot or patch of nothing, then a perfect looking surface again. This is not always, some of my canvas will look great, but it’s hard guessing, I don’t want to do larger pieces until I know what I am doing wrong lol. Sometimes I will do a canvas pour then do a pour into a necklace bezel and do the same when resin day comes around. I have yet to experience this with a bezel, so I thought to make a tape “bezel” around the canvas, even tho I really want to do the sides as well (1.5″ canvas sides look cool and need resin love too! lol) that resin is stubborn, if it doesn’t want to go in a spot it will find a way to avoid it unless I pour a 1/2 inch pour and win the surface dent battle… and then have an entire 1/2 inch of resin on a painting LOL.

I read so much about heating of resin etc. I see people pour the resin on the paintings and it flows off the side leaving a lovely surface. So I am assuming (uh oh lol) that I can do the same and not worry about the resin heating up enough… but well… it’s resin, I am afraid to assume too much, or anything really. Help!

Mahalo for your site. I wish more things could be shipped to Hawaii, I would be on here more often getting supplies, not just molds and advice lol!

Hi Judy, it sounds like maybe you aren’t mixing enough resin to fully cover the surface of your artwork. Here are a couple of links to help you with the math on how much resin you should use:

https://www.resinobsession.com/resin-frequently-asked-questions/how-much-resin-do-i-need/

https://www.resinobsession.com/resin-art/how-to-apply-a-glossy-resin-layer-to-a-painting/

Hello! Thank you for your reply, I am thinking I am using enough, because of my tape surrounding the edge of the canvas technique that allows me to not pour over the sides. So I can build up enough resin however, those spots are literally pushing the resin away. It has so many variables that it could be anything, frustrating since in this case I can’t alter many variables. I was hoping others have had this issue and you might have come across it before. I will upload a photo somewhere and post a link in the near future so I can show you exactly the wonkiness I am encountering.

Once again thank you so much for the reply!

Hi Judy, I hope I can comment too. I have had this exact thing happen to me and have yet to solve it. I left a problem comment on this site a few weeks ago and Katherine suggested cleaning the indentations with baby wipes, in case it is resin and suggested not to use dawn in case it damaged the painting underneath. I did use the wipes and then decided to risk it and also used dawn and washed the painting extremely well. I added a second coating of resin and once again despite everything the indentations came back. Just as you said the resin just avoided certain areas. So later I washed the painting again with dawn, I also tried with alcohol, left it to dry couple weeks. I did as Katherine suggested to you, calculated the correct amount of resin, made an edge barrier with tape so it couldnt go over and so there is plenty of resin. I’ve just finished coating the painting for a third time. It seemed to coat all of the areas that were a problem previously while I was working with it. I used heat gun and everything seemed great. Now an hour later I just checked and in one area the resin has moved and left a very shallow but definate area that it didnt seem to like, not as bad as before but the surface is not smooth. I am at a loss what the problem is and how to solve it. I’m guessing after three coats that this painting is shot. (The painting is 30inches by 24inches fyi). Just wanted to let you know its not only you 🙂

Ugh! How frustrating! It might be worth mixing just enough resin to fill in the voids and allowing them to cure. Once you know they are securely adhered to the painting, then recoat with another layer of resin.

Great idea Katherine thank you. Do you think 4 layers of resin is okay, can it be too much? I have no clue, this is my first attempt coating a painting.

It won’t be a problem in the sense that the resin should stick to itself fine. What I don’t know is how heavy the extra resin will make the piece and any extra reinforcements you might need to hang your art.

I’ll try. Thank you so much for your replies. I really really appreciate it. You’re the best 🙂

Hi, what is the best way to clean out my silicone moulds after a dud batch of resin hasn’t set please.

Has it fully passed the cure time?

what is the best resin to use for a deep pour that will be very clear? Im making a tall vase with an under water scene, sand, shells, fish and with a candle holder on top. I just didn’t want to make a lot of small pours where you can see each layer. Thanks in advance..

What’s your experience with resin?

I have been making coaster with amazing clear cast….they all came out beautiful

Hello! I’m new to resin and I’m experiencing a few problems. I’m using Amazing Clear Cast resin for my projects. I mix glitter into the resin right before pouring, but it gathers together into the middle of the resin once it’s poured. It disperses nicely throughout, but there’s always a fine layer on top of clumped together glitter (using micro glitter). It’s almost like it’s drawing into itself. Also, can I dome with resin I already made up or does it need to be specific doming resin? I also can’t get my resin clear. There are a million tiny little bubbles in it or it’s cloudy. I’ve mixed slowly and at 70 degree temp and kept the bottles in warm water for 5-10 minutes prior. I heat the top as well with a lighter but it’s never crystal clear. When I color the resin it’s fine but I can’t get anything clear.

What you are describing with the glitter commonly occurs. Once the resin starts to cure, you can add another layer of glitter to the back to make your charms look even.

If you want to dome resin, you need to make sure you are using a doming resin. The Alumilite Amazing Clear cast is a doming resin, so you are all set there. If you are ever unsure, ask the manufacturer.

Are you pouring your resin into molds? If the mold is cold, that can lead to bubbles. Warm it up with a heat gun before pouring your resin.

Hi ive been having problems applying the final coat of resin to gloss my work. After sanding down with a fine sandpaper, and applying the liquid resin to the top of my dome bead, the liquid keeps getting pulled to certain areas, leaving parts empty and thus patchy. Any advice would be most appreciated! =)

Unfortunately, this is the nature of resin. It doesn’t like to stay on a curved surface. I suggest using a thicker mixing resin and rotating the bead during the curing process.

I mixed up some resin pieces and I’ve noticed over time that they’re starting to bend and become flexible. I’ve used different resin types and it’s hit or miss. One I’m pretty sure was past it’s expiration date but the other resin was fine. So why are the pieces not hardening properly? Is it because I’m not mixing my resin and hardener well? Would pouring another layer on the back with better mixed resin help keep it’s solid shape?

What kind/brand of resin are you using?

Hi there!

I posted this comment already but it’s not showing up for me so I apologize if it’s a duplicate.

Firstly, thank you for all of the work you put into this site! It’s so helpful.

Secondly, I’m having an issue that I hope you might have some insight on! Pieces that I’ve made in one particular silicone mold are coming out with strange surface imperfections. I’m not sure how to describe them so here’s a link to a small album showing the pieces themselves as well as the surface of the mold

This had never been an issue with this mold before. It was washed gently with soap and water and dried before use. I saw that the marks were on the mold but couldn’t get them off so I hoped they wouldn’t translate to the pieces, but unfortunately they did. 🙁

So, a couple of questions:

1) Is there any way to fix the pieces and make them look less… weird? Would doming the front work or would it just be a waste of time and resin?

2) Is there any way to salvage the mold itself? I have no idea what happened to it.

Thank you in advance!

Hi Brianna, as long as the imperfections are minimal (1/16″ or less), applying a layer of doming resin should fill in nicely.

.

As for the mold, it’s hard to say if it can be salvaged or not. Can you link to a picture of it as well?

Hi again,

I did end up adding a doming layer and at least while wet the imperfections did seem to disappear. Yay!

I actually included a picture of the mold in the album, it’s the last picture. 🙂

Thanks again!

Glad to hear things worked out with a second pour. Yeah!

.

I do see the mold now. Didn’t scroll down far enough. Whoops! Unfortunately, there is no way to fix this mold. It looks like this is an inexpensive mold for crafting, ice cubes, etc? If so, those molds typically don’t last as long as molds directly intended for resin use. What you see here has been my experience with them as well. To prolong the life of your molds in the future, a good mold release will help. I like the Petrolease mold release and use it on all of my plastic and silicone molds. You can find it in our store here: https://shop.resinobsession.com/collections/tools-and-supplies/products/petrolease-non-silicone-food-grade-mold-release

Ah, bummer. It was fairly inexpensive but I did buy it from a source I trusted (MiniatureSweet) and it specifically said that no release agent would be needed. Nothing I’ve made in it has ever stuck, so I’m not sure how it got ruined. 🙁 Oh well. Live and learn I guess!

Thank you for your help!

Hello again! Thank you for your help before. Just a minor issue now. When I pour resin that I’ve added darker colored Pearl Ex pigment to (such as black), it swallows up the glitter I’m trying to use. Micro glitter shows, but when I use bigger pieces such as stars it won’t show in the final piece. I’ve tried sprinkling the glitter first into the mold and then the resin on top of it, but that doesn’t work. Thoughts?

Sounds like you need to try pouring glitter and resin in one layer and the black in another.

Hello Kathy, I did a bathroom with resin, I bought it in my country. At first the resin worked pretty well, nice colour, texture and everything. It didn’t last long, the owner of the bathroom complaint to me that it had turned yellow and is sticky somewhere, like it never got cured. The yellow thing is ok because it happened with the same in another toilet ( mine) but the sticky problem is not good and I don’t understand why.

Another thing is that after taken a shower the water leaves a stain, brown one, that comes out only with a thinner. ( I know is not the better way and the thinner is not good but is the only way right now). I can send you a picture.

In case everything is done wrong, what can I do to make thing right, (what resin to order; I live in Europe) at least for my client which is very upset and I’m worried. Thank you!

I’m sorry to hear things aren’t working out for you. This troubleshooting article should help: https://www.resinobsession.com/resin-frequently-asked-questions/resin-troubleshooting-tips/

Hello. I have one problem. Why some white oil painting turns yellow?

Hi Katherine.

I have made molds out of 100% silicone (black). The resin does not cure or is tacky! in them on the outside. I have cut the resin open after 24 hours and the inside is hard. I make sure that I mix hardener and resin very thoroughly. Completely confused!.

What kind/brand of resin are you using?

I am using Famowood Glaze Coat. I have used this successfully in other type of molds such as plastic molds for Making Ice, such as stars, ovals etc…I am wondering if it could be the Black Silicone! thanks for any help you can send my way.

Unfortunately, resins like this aren’t meant to be used in molds. They are generally meant to be cast on surfaces of an 1/8 inch depth or less.

ok thank you Katherine

Hello Katherine!

I tried to do a toilet in the same effect as a . The problem was that in some parts of that is not cured. The resin came in a plastic box with no label in it. I used acrylic colors with the resin(I used those before and they worked perfectly). In the parts that is not cured has like black spots, is dirtiness but is stuck there. I don’t know how to fix it now> option one is to levigate and to clean it and then to try the resin again, and the second is to take it out and to do it from the begining? I am in a crossroad. Please advice! What’s more I live in Europe and I don’t know about the shipping! Than you!

I don’t know what to tell you since I’m not sure what the black spots are. If those spots are simply sticky (and not gooey), you should be able to recoat them with another layer of resin and have it cure, although it may not get rid of the black spots.

I wanted to buy Total Cast resin. I want to use it on a toilet surface. Will it work for a toilet?

Work in what way? I want to be sure I completely understand what you want it to be able to do before I comment.

Hi, Katherine.