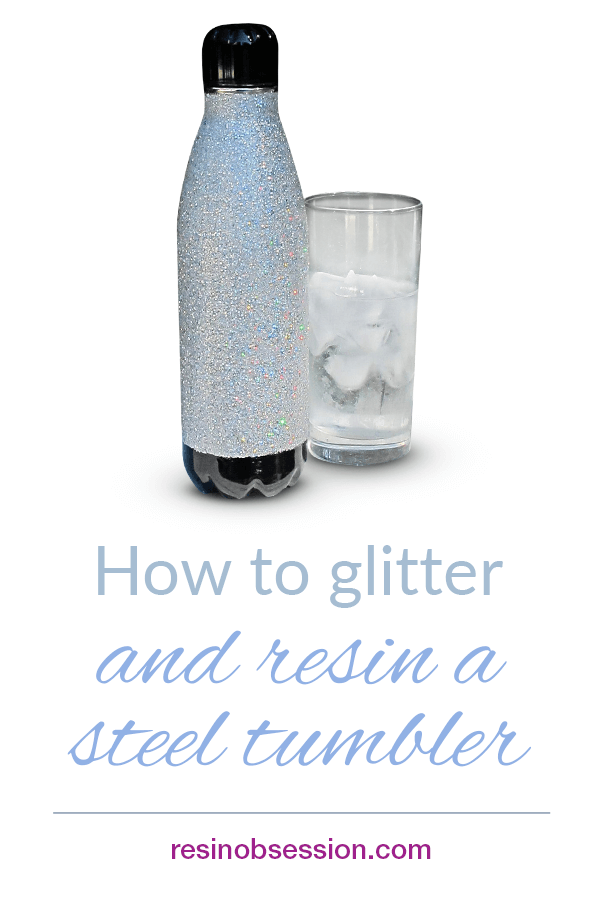

Looking for another surface to cover with glitter and clear epoxy? What better way than to glitter and resin a stainless steel tumbler. You’ll love having a beverage holder that’s sparkly while you’re sweaty. Plus, you can personalize these to gift for birthdays, holidays and any day of the week that ends in Y.

Resin supplies needed for the glitter part:

- Stainless steel tumbler

- Clear-drying white glue

- Foam brushes

- Glitter

- Painter’s tape

- Food safe epoxy

Step 1: Wash the bottle

Wash your bottle surface with soap and water to ensure it’s grease-free. You must have a clean surface for the glue.

Step 2: Add tape

Step 2: Add tape

Apply painter’s tape to both ends of the tumbler. Let the grooves on the tumbler serve as your guide.

Add tape anywhere you don’t want resin and glitter on your tumbler.

Step 3: Coat with glue

Use a foam brush to apply glue to a section of the bottle.

Step 4: Add glitter

Sprinkle glitter on the glued area. Repeat the areas until your entire tumbler is covered. Allow drying for several hours.

💡 Pro tip: Having a plate underneath will catch the glitter and allow you to pour it back into the container to reuse.

After adding the first glitter layer, check for spots that weren’t completely covered. Add more glue and glitter as necessary.

Allow drying overnight.

Step 5: Add epoxy

Mix 1 ounce total of food safe resin. You want to use food-contact safe resin in case someone needs to lick the sides of the bottle to clean up a spill.

Use a new foam brush to apply the mixed resin to the glitter surface of your tumbler.

💡 Pro tip: When you’re done, throw the brush away. You’ll drive yourself crazy trying to clean it.

Rotate the tumblers every five minutes for the next hour. The horizontal one rotated a quarter to a third of a turn each time. The vertical tumbler rotated 180 degrees.

Doing it this way means you’re babysitting your resin for the next couple of hours. If you want to resin stainless steel tumblers regularly, you’ll want to invest in a tumbler spinner.

Step 6: Remove tape

After the resin cures for two hours, remove the tape. Don’t wait until the resin completely cures for two reasons:

*If you let the resin completely cure, the tape edge will be resined to the bottle. You won’t be able to get it off.

*If resin seeps underneath the tape, you’ll be able to wipe it off with some acetone while the resin is sticky.

Let the bottles finish curing overnight.

Ta-da! You just learned how to glitter and resin a stainless steel tumbler.

This tumbler will be perfect for a refreshing beverage when you need it.

Ready to craft with resin but anxious about taking the first step?

I get it. No one likes wasting their time and money on something you wouldn’t show anyone. It’s why I wrote the ebook, Resin Fundamentals. I’ve condensed my 17 years of resin experience into the book that will get you to resin pro status in only an afternoon. Buy your copy now and download the PDF in minutes.

Unpublished Blog Posts of Resin Obsession, LLC © 2023 Resin Obsession, LLC

This is so cool I didn’t know you could do that. Are you happy with the result after trying it for a while?

So far, but ask me in a couple of months after I have had a chance to use it. I’m curious how good it is going to look after banging it around a bit. 😉

It will be interesting to see if the resin affects the insulating properties of the tumblers – less condensation on the outside, cooling effects, etc. Or are these double wall tumblers? Mine is single walled, and sweats when I have a cold drink in it.

Hadn’t thought about that! It’s a single walled tumbler. I will have to see if it sweats.

OK.. now that several months have passed, how did the bottle & epoxy hold up with use, and did the condensation affect the seal of the epoxy?

I’m pretty happy with it. I hand wash only and have been happy with how the glitter still looks.

I wanted to resin a globe after applying shards of glass but didn’t know how. I will try slowly rotating it as you did the tumbler. Hoping for the best. Thank you.

Hi. I’m about to resin my first cup and have been putting it off cause so scared I’m gonna mess it up lol plus I don’t have a cup turner, so Want to do as much research as possible. I came across your video and got very excited about the possibility of doing it vertically. My only question, you said you rotated it 180°. was that you turned it from the bottom to the top and the top to the bottom or you turned it around 180°? If that is a stupid question please remember this is my first one LOL

Yes, you got it! Plan on rotating it for the first hour or two (depending on the resin you are using) and it should be fine. Good luck!

I am about to resin a cone shape piece of styrofoam… you were very helpful cause I wasn’t exactly sure how to go about a non flat piece. Luckily I found this post! Thanks!!!

Can you add a decal before you resin it? For example something made from a circuit?where do you purchase your resin? Thanks Terri

Hi Terri, yes you can use a vinyl decal before applying resin. You can purchase resin in our shop here: https://shop.resinobsession.com/collections/resin

Beautiful work, Thank You for Sharing…

How has it held up now, after more than a year? On the vertical one, did you flip it upside down, when you turned it 180? If you don’t see this, or can’t remember, I understand.

They both have done well. I have tried to treat them well, but overall, am happy with their durability.

Don’t soak it in water, Mod Podge is Water based, and will peel off.

Did you use the water proof mod podge?

No, I did not.

Ok, thank you.

I am curious, will any normal craft glitter work in jewelry and tumblers?

Yes.

Oh WOW!!! So being charged like 9 bucks for an ounce or two of glitter isn’t really required??? OMGosh! I keep seeing posts about use this type, or that type, or this one…and btw, that glitter is $9 bucks. I get it, people need to make money, but what is the solvent safe scenario? That’s why I grew concerned. I have to admit, from what I’ve been reading, if you don’t use a certain type of glitter, it will MELT, or the colors will bleed. So, in theory, that’s not true? Sorry…to be a pest!

I don’t know what to tell you. I have never had a problem with glitter melting in resin. I’ve never been concerned about using a ‘solvent safe’ glitter.

I’ve seen recommendations to spray or brush on a sealant before applying resin.

How well do you think applying glitter and sealing it with the Alumilite Amazing Clear Cast Epoxy Resin to a personalized license plate will hold up? Weather wise, will it stay on?

I think it will stay on, but will yellow over time.

I have a question. I’ve been seeing where people are having reactions to epoxy. Is epoxy safe to use with out a respirator?

Hi Melissa, I’m so glad to hear you are taking resin safety seriously! We have a few articles on the topic here: https://www.resinobsession.com/tag/safety/ If you feel safer using a respirator, even if it’s not required, then do it. 🙂

I bought a personalized glitter mug at a craft fair. I didn’t realize until I got home that there are some imperfections with the cup. There is glitter and resin on the top part of the cup making it a little hard for the lid to go on at certain times. There are also some spots on the cup where the lady left some resin making the cup have rough patches. Any tips (if any) to get it off with out destroying the design on the cup? Any tips and tricks are much appreciated.

Hi Breanne, it’s hard to say without seeing the cup. Is asking the maker to make the adjustments not an option?

Hello! I have a few questions for you 🙂 So I painted a bottle for my friend using acrylic paints. I used a spray on coat and did many layers, letting it dry each time. It seemed to be doing the job well but after about a week the paint started chipping off. I’m planning on doing resin on it, thanks to your wonderful video. I’m wondering if the acrylic paint will for some reason be a problem with resin, and if it’s ok that the brand of bottle I have is different. (hydrapeak) Thank you so much for the video! I’m looking forward to your response 😀

Hi Amber, resin adheres well to acrylic paint.

I’m just now seeing this! Thank goodness. I can use Modge Podge and coat with resin at the end. One question; can I use more than one coat of a thin resin? I assume I can, but you know what a-s-s-u-m-e does!

Yes, Susan you can.