And you’re finding your resin has an edge

- Whether you use plastic or silicone molds

- Regardless of the resin type

- You use resin colors or keep it clear.

Ready for the good news?

You didn’t do anything wrong.

Then what the heck is going on?

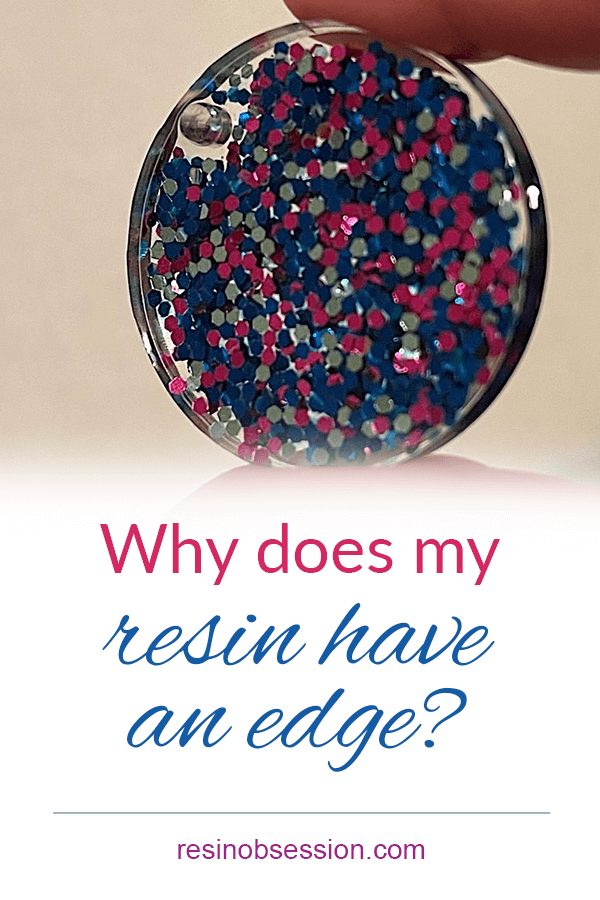

Let’s take a closer look. You should notice the resin that touched the mold surface cured as you expected. It’s the back part of the mold (the side exposed to air) that cured with a sharp edge.

Why?

[Hang with me for the next 30 seconds.]

It has to do with heat and surface tension.

Do you remember your resin warming up when you mixed it? Well, hot things like to expand. So when you poured your resin into the mold cavity, it took up more space than it did later — after it cooled off.

The thing is, though, the resin in the center shrank, but it didn’t shrink away from the mold sides. That’s due to surface tension. It’s why when you demold, there’s an edge on your resin, and you wonder what you did wrong.

👉 By the way, if you want to add to your silicone mold collection, here are our customers’ favorite Resin Obsession silicone molds:

What can you do to prevent a resin edge?

You overfill your mold a smidge, knowing the resin will shrink a little bit.

How much exactly is a smidge?

Well. I don’t have an exact answer for you, but here’s how I approach it.

Fill your mold cavity so that the resin is level with the side of the mold.

Then, add more resin until it rises slightly above the edge of the mold. This might only take a few drops of resin but could take more depending on the size of the recess.

💡 Pro tip: The more you use a resin, the more you will get a feel for how much you need to overpour so that it shrinks to level while curing.

Do you need to fix a resin edge?

Yes. These edges can be sharp enough to scuff a table or scratch someone.

How do you fix a resin edge?

You have two options:

Option 1: Sand

Use wet/dry sandpaper or a rotary tool to remove the sharp edge.

💡 Pro tip: While using a rotary tool takes off resin quickly, it’s easier to have a WHOOPS moment. I’ve never accidentally sanded off too much resin when using sandpaper.

Option 2: Add more resin

Apply a flood coat of resin to the side with an edge.

💡 Pro tip: You must use a resin that mixes thick and is meant for giving coatings if you’re going to fix it this way. The Resin Obsession crystal doming resin is perfect for this step.

Either method will smooth out your resin edge.

For extra punches on your Resin Obsession resin nerd card, you can watch this five-minute video, where I dive into more of the details on the two repair options.

If you liked learning about why your resin has an edge, I’ve got even more good stuff for you.

Plus, that’s the official sign that you have a #resinobsession.

I’ve condensed my sixteen years of resin know-how into a downloadable resin beginner ebook you can get right now. Buy the ebook (for less than the cost of a resin kit), and you can stop wasting time watching free videos on youtube. Like, let’s you back to creating!

Unpublished Blog Posts of Resin Obsession, LLC © 2023 Resin Obsession, LLC

I have had this happen and used a deburring tool to get rid of the sides. It works really well.