Scenario 1: Your resin is flash curing.

If your resin is hot and smoking, you need to do something about that NOW. Immediately go to this article about what to do when your resin overheats.

Once you’ve got things under control, finish reading this article about how to cool down resin.

Scenario 2: Your resin splintered.

Everything was okay when you mixed the resin, but you look later to find out your resin cracked. This can be a problem when your resin gets too hot.

In either case, you need to know how to cool down resin.

Now I know what you’re thinking — and you’re right.

I spend a ton of time telling you to ensure your resin and surroundings are warm, and now I’m telling you to cool it down.

Cooling down resin is the exception to the rule. But there are times you need to know how to do this.

But, before we get into that, let’s talk about resin and why resin gets hot to begin with.

In the case of two-part epoxy resin kits, there is a Part A (resin) and the Part B (hardener). The two chemicals don’t do anything by themselves, but when mixed together, the combination builds heat. This heat is what causes the resin to cure or harden. So, feeling your resin get warm is perfectly normal and necessary.

Why would you want to cool down resin if heating up is so important?

The resin can cure too fast.

Resin reactions are mass-dependent. The more resin you mix, the more heat it produces. That heat builds upon itself and can speed up the reaction. Your resin may harden before you can pour it into your resin mold or coat your artwork surface.

The resin can crack.

After the mixture warms up and solidifies, it will cool. If the resin heats up too much, it will cool off too quickly. The resin can’t move and shift with the rapidly cooling temperature. It will crack to release the tension.

The resin mixture can start a fire.

While rare, if resin gets too hot and is mixed in something that isn’t heat-safe, it can melt the container and start a fire. It’s why you should have a metal can and a fire extinguisher nearby whenever you’re resin crafting.

What steps should you know about how to cool down resin?

Step 1: Avoid resin overheating

Resin that overheats rarely produces a positive outcome. That means:

*Mixing no more than the manufacturer’s recommended maximum mixing amount

*Keeping your room at the appropriate temperature

*Confirming your resin kit components are warm but not hot before mixing them

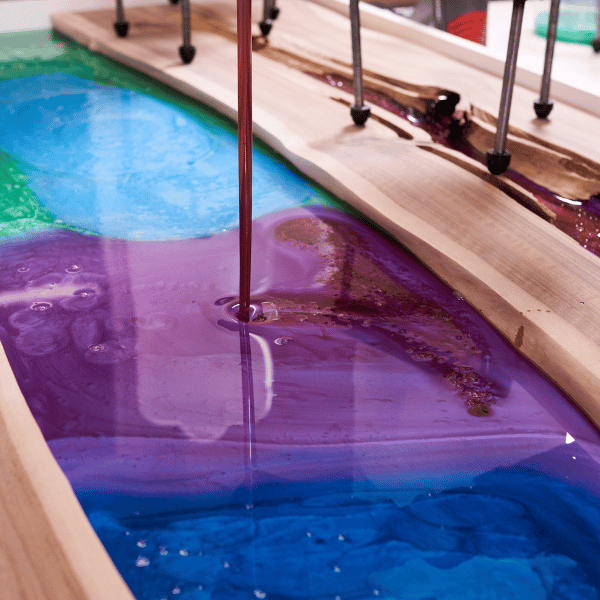

Experienced resin artists know there are times that a resin mixture might overheat. Resin projects that need large volumes of resin poured in thick layers are the most prone to this. Projects like this include:

*resin river tables

*giant paperweights

*dense sculptures

*and other deep pour projects

For these times, you want to use a slow-curing, deep pouring epoxy casting resin. These epoxy resin formulas take days instead of hours to cure, allowing the heat to build up slowly.

Step 2: Move the heat away from the resin

How do you do this?

Elevate the resin surface

Lift your resin mold or surface so that air can circulate on all sides. The heat will escape easier, making cracking less likely.

Use a fan

Once you elevate the surface, use a fan to push air away from your resin. This is the same concept as when you blow your breath over food that is too hot. The air moves the heat away and allows the resin to stay cooler.

Set your resin on a cooling surface

If the resin feels like it is warming quickly, put the resin and container combination in a water bath. Be careful here, though, as water and resin do not mix. Literally! The resin will not cure if it’s contaminated with water.

Should you find your resin has heated quickly and is starting to smoke, don’t inhale those fumes.

Put the hot resin cups in a metal container. Carry them outside. Otherwise, open windows to allow fresh air into the room. Do not touch again until the resin has cooled off and the smoke disappears.

Want to learn more about the basics of creating with resin?

Then you will want to get a copy of my ebook, Resin Fundamentals. I’ve condensed my 16 years of resin experience into something especially for newbies. You can read the PDF book this afternoon and feel confident trying your first or next resin project. Buy now, and you can download it to read in only a few minutes.

Unpublished Blog Posts of Resin Obsession, LLC © 2023 Resin Obsession, LLC