Hello, Resin Obsession fans! Karen Bearse here with a new experiment/playtime using stamp pads as resin molds. I have had this idea for a while, speculating in my brain. Today, I decided to act on it.

Resin Supplies:

- -Amazing Casting Resin

- -Casting Supplies- measure cup, gloves, stir stick, timer.

- -Various stamps- I used rubber, clear, and foam.

- -Mold Release

- -Parchment paper

I had a few questions that needed answers like:

- Which stamps will work with resin? Red rubber, white rubber, clear, cheap stamps, etc.

- Will the resin stick to the stamp and damage it?

- Do I have to use a mold release?

- Will the stamp pad still work after having resin on it?

I gathered my supplies and had some extra molds on the side in case I poured too much resin. The Alumilite Amazing casting resin cures quickly, which gives me quicker results from my experiments. Don’t use your favorite stamps unless you are willing to damage them.

Step 1: Prep the stamps

First, I took stamps made of different materials: Red and white rubber, foam, and clear. Then, I spritzed them with mold release and let them dry.

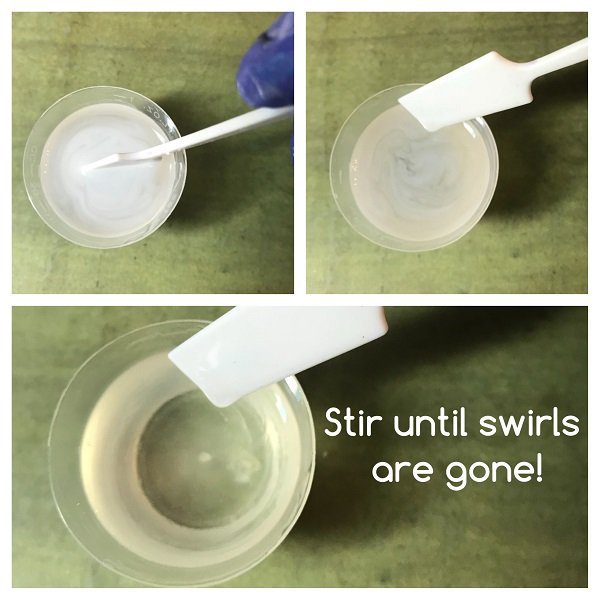

Step 2: Measure and mix resin

Next, add 1 part of Part A and Part B of the resin (it mixes 1:1), then mix with a stir stick. Stir time is 30 seconds, but I realized what you are looking for is to mix until the swirls disappear. The resin should also begin heating up in the cup. Pour over the stamp. It is hard not to have the resin pour over the edges, but this is okay since the resin will just peel away.

If you have never mixed resin before, you will definitely want to learn how to measure and mix resin. This resin starts curing two to three minutes after mixing.

Step 3: Apply the resin to the stamp pad

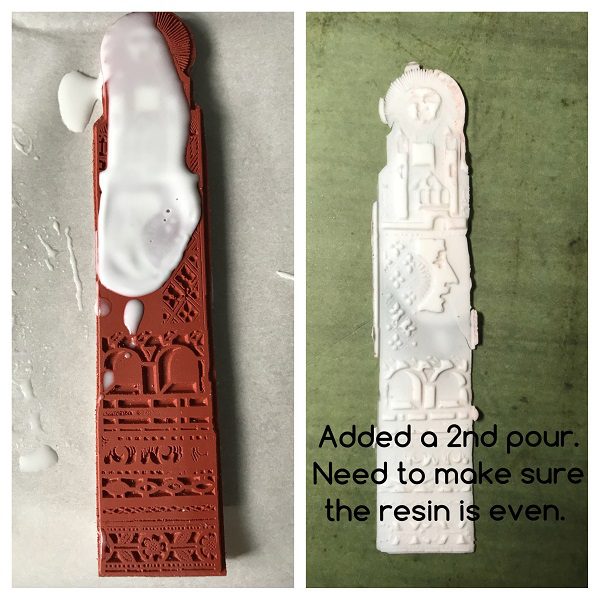

You can see here that the resin is starting to cure. Wait until the resin turns white, which should take 5 to 15 minutes, depending on the temperature in the room and humidity level. It’s easier to pull the resin when it is still slightly soft but no longer warm. That’s about 10 minutes after mixing.

If you don’t let the mold release dry, you’ll make lots of bubbles and your resin may not cure. Alumilite Amazing casting resin is a polyurethane resin and is very moisture sensitive.

Have all your materials ready, especially with this resin type, as it has a short one-minute work time. It is better to do smaller pours well than try to mass produce with this product, as it just cures too quickly. The bonus, of course, is not having to wait to see the result. It’s well worth it when using stamp pads as resin molds.

You do want a thick enough layer to get a good impression. Pop the air bubbles with a pin and a heat tool like the Zap embossing heat tool. The challenge is once the resin starts to set (in as short as 90 seconds), it’s almost impossible to pop the bubbles. Also, the heat makes the resin cure more quickly.

I realized I would instead just let the bubbles occur as they don’t bother me. Plus, I intend on coloring these pieces so the bubbles will not be noticeable.

Step 4: Remove from the stamp

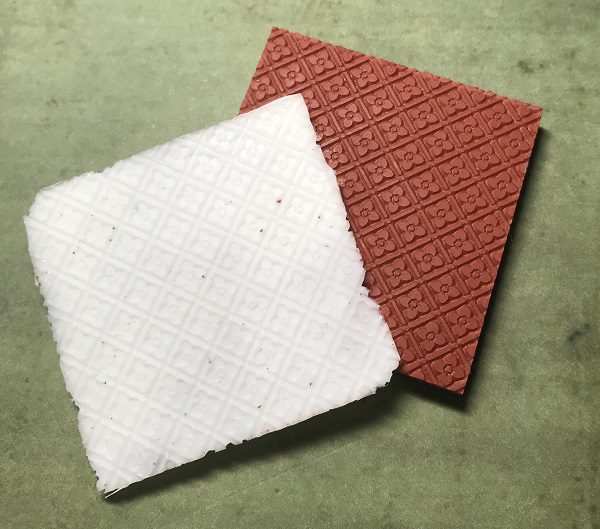

Once the resin is solid, carefully peel the resin away from the stamp. This takes 10 to 15 minutes. You may get a bit of separation of the foam from the rubber, but that doesn’t bother me as I can always re-glue it. In some cases, if resin was on the edge of the stamp, it pulled some of the foam. So again, if you are worried about ruining your stamp, use some that you can part with first to see the results.

The foam stamp did not work, and the resin ruined the stamp, so I do not recommend using foam stamp pads for resin molds.

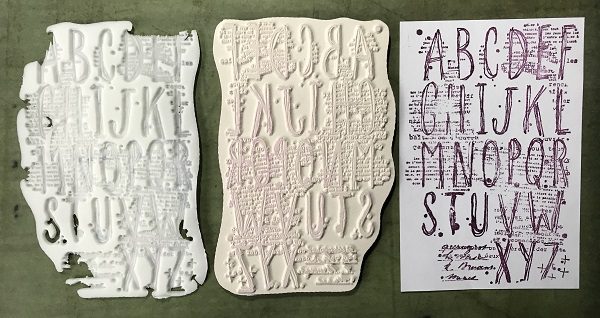

I say ‘cleanish’ because I wet the stamp and cleaned it with a rag with some very light paint on it, which transferred to the resin. Oops.

I was amazed by the results and the quality of impressions with the variety of stamps of different thicknesses and details. However, the stamp that shocked me on how well it worked was the super detailed yet shallow stamp by Anne Butler. It created a perfect impression.

If the stamp is a deeper cut, it will likely need two pours to cover. The Amazing Casting Resin does not produce a dome. The resin fills the cavity of the stamp but does not sit on top of the stamp. This leaves the higher peaks of the stamp bare. The solution is once the resin hardens a bit, a second pour will sit on top of the first, covering the higher areas.

Here are some of the resin pieces with the stamps and their stamped images. After using the stamps as molds, I stamped them with Distress Ink and was very happy to find that the resin did not appear to damage the stamps. The star is Seth Apter by PaperArtsy, the square is Anne Butler by Colorbox, and the butterfly is Darkroom Door.

If you are only pouring on part of a larger stamp, try to keep the edges of the pour clean and thick. Drips and thin layers are harder to get off of your stamp. The stamp above Lynne Perrella by PaperArtsy.

Here’s what I learned from my stamp pads as resin molds experiments:

*Removing resin from the stamp when it is still soft works better and means easier removal. Bonus — you can still trim the edges if you need to.

*If ink is on the stamp, even archival, it will come off with the resin. I’m going to investigate this cool effect more. If you want a clean image, the stamp must have no residual ink.

*On a larger stamp, pour resin down the middle and let it move naturally to the sides. You can add more resin if needed or even do a second pour if the stamp is not entirely covered.

*The resin came off the back of stamps with grey backing without a problem. However, it was hard to get off the stamps that were backed in black (Unity Stamps). Simply give the back a spritz of mold release.

Want to learn more about working with resin but don’t know where to start?

Get your copy of the ebook Resin Fundamentals. It has the essential details you need to know to create with resin, even if you have never worked with it. Buy the PDF book now and get a download link in minutes.

Originally written by Karen Bearse

Unpublished Blog Posts of Resin Obsession, LLC © 2023 Resin Obsession, LLC

Very nice and thanks so much for your teachings.

You are very welcome!!

Wow these turned out great!

Thank you for sharing and I can’t wait too see how you use them 🙂

I am a wood turner and I would like to use your product on my bowls. What product should I use to tint the product in red and green colors?

Hi Bill, we have colorants for resin here, including red and green colors: https://shop.resinobsession.com/collections/colorants

Thank you for all that information . It was very interesting in your findings. Thanks for sharing.

So cool! Did you try this on clear stamps?

Yes! You can see them here: https://www.resinobsession.com/resin-tutorials/alternative-resin-molds/

Hi I been thinking of doing rubber stamps as molds for resin but been scared to i don’t want to waste the rubber do you if I can use my pink rubber stamp with resin? Also I use uv resin will the uv led lamp damage or burn the pink rubber? I would appreciate your help a ton thank congrats I love your teachings

I haven’t tried UV lamps with rubber molds, so I’m not sure if it would damage your stamp pads.