*Are resin molds expensive?

*Can you use anything as a resin mold?

*Will you need to do anything special once your resin comes out of the mold?

Here’s the good news — you’re on the right track to be thinking about all this stuff. I had those same questions when I started as a resin artist 17 years ago. I wasted so much resin figuring out what worked and what didn’t with molds for resin.

Plus, I dropped swear words like cotton-headed turkey fink and liver-spotted baboon hound. Yeah. Those were some troubling days.

I don’t want that to happen to you. So let’s dive into what you need to know when you use molds for resin.

Why use molds for resin?

Let’s start by talking about what resin is. It’s a liquid that, when activated, will produce heat to form a solid mass. You’ll activate resin by adding a catalyst (two-part resins) or UV light (UV resin).

How does this relate to molds for resin?

When you activate the liquid, and then pour it into a mold, it takes on the shape of the mold. And it keeps that shape after it cools. That’s why resin helps you make coasters, jewelry, paperweights, and more.

What makes a good mold for resin?

You might be thinking that any vessel will make a good resin mold.

Wouldn’t that be nice?

Unfortunately, it isn’t that simple. There are three things you need to know about choosing molds for resin.

#1: The mold material must be able to take heat.

Because the resin gets hot, there is a risk of melting your mold or the resin starting a fire. That’s why styrofoam containers and paper cups don’t make suitable molds. Instead, it needs to be material, like silicone, that can take heat as high as 200F.

#2: The mold material must be flexible.

You can pour resin into a glass baking dish. But once the resin cures, you’ll find the resin has done a great job sticking to the dish. Because the glass is rigid, you can’t flex it to remove your cured work.

But you will have a beautiful dish of resin.

#3: The mold material must be thick enough to release the cured resin.

You might be tempted to use plastic candy molds to make resin crafts, but I’ll save you the disappointment. While your resin will cure, it will stay forever stuck in your candy mold. The same applies to candle molds. And you can see what happened when I tried to form resin in a soap mold.

So now that you know what doesn’t make suitable molds for resin, what does make good molds for resin?

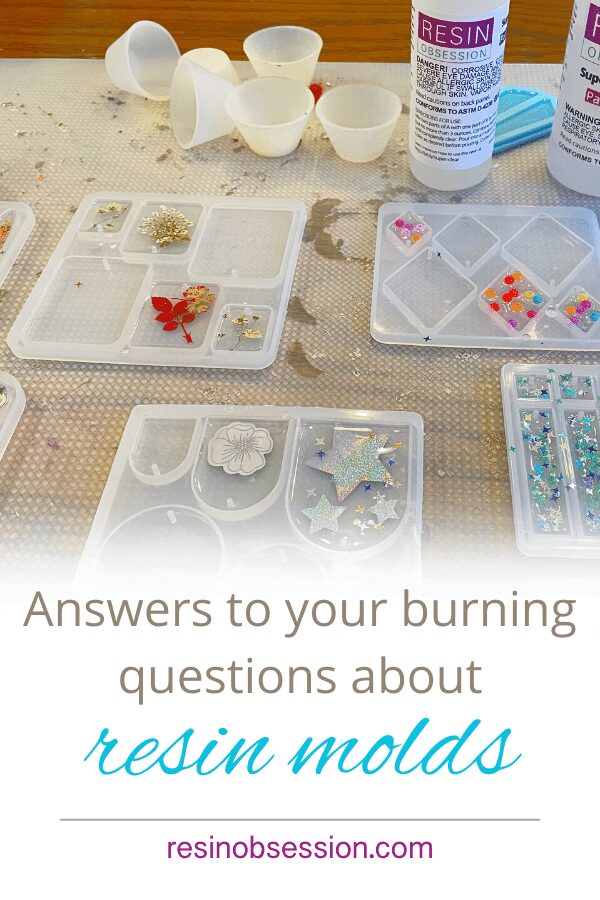

The easiest place to start is with molds designed for resin. We’ve got a bunch of them in the Resin Obsession store. I use every mold style before we ever sell them in the store. If it doesn’t work for me, I’m not going to offer it for sale.

Here are some of our customers’ favorite molds for resin:

The molds we sell are made with silicone or polypropylene plastic. Both types of molds are flexible and release resin quickly. Not only do we have them in a bunch of different shapes and designs, but they’re reusable.

How do you know if your resin molds will make a glossy finish?

Here’s the BIG rule you need to know about resin molds.

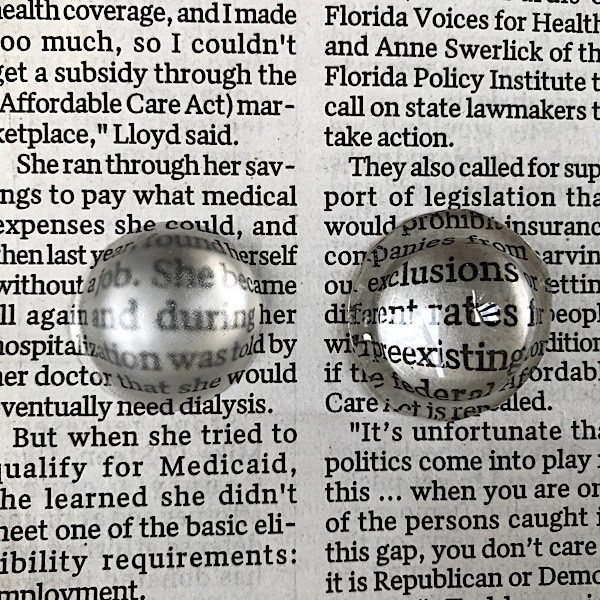

Whatever the finish on the mold, that same finish will impart onto your resin castings.

That means if your mold has a shiny molding surface, your resin will cure with that same shine. The opposite of that is true too. A frosted surface mold will make frosted surface resin castings.

What if your molds for resin don’t have a shiny finish?

Don’t worry. You can still use the mold. If you want your resin to have a shiny finish, you’ll need to take extra steps after demolding to make the resin shiny.

Option 1: Glaze with resin

You can use resin like a glaze and apply a coat to your flat surface to make it shiny.

Option 2: Use polish

If your surface is curved or detailed, you can get a shiny surface by using a resin polishing kit.

Can you use silicone baking molds with resin?

So, while the easy answer is yes, you may not be happy with the finish. Baking molds usually produce a frosted or cloudy surface. That means you need to take extra steps to give your resin a glossy finish.

⚠️ IMPORTANT: If you do use baking molds with resin, don’t use them with food again.

Can you make molds for resin?

Yes! The easiest way to do this is to use two-part silicone mold putty. Simply ”eyeball” an equal amount of the two parts and blend them together with your hands. Then, form the putty around the item you want to mold and you’ll have a DIY mold.

💡 Pro tip: If you want the resin to cast shiny in that silicone mold you’re making, make sure the thing you’re molding also has a glossy finish.

How do you keep molds for resin in top shape?

Using a resin mold release protects your mold against microtears and makes demolding easier. You won’t have to twist your mold as hard to demold it.

⭐️ BONUS: Here are other tips for caring for resin molds.

What resin should you use for resin molds?

You’ll get the best results by using a casting resin. Casting resin and molds for resin go together like kitty naps and fleece blankets.

How?

Casting resins mix in a thin consistency, which allows bubbles to escape quickly. That means you can pour it in deep layers or intricate patterns with less of a chance that you will trap bubbles.

Best casting resin for small pours

Resin Obsession super clear resin

Mix between ½ ounce and 3 ounces at once

25-minute working time

Cured to demold in 8 to 12 hours

Best casting resin for large pours

Resin Obsession deep pour resin

Mix between 3 ounces and 3 gallons at once

30-to-90-minute working time

Pour up to two inches thick in one pour

Can you put molds for resin in the oven?

Say what? You’re in a hurry to cure your resin?

You can do that too.

Step 1: Set the temperature to 150F and mix and pour your resin as usual.

Step 2: Place your resin-filled mold in the oven for five minutes.

Step 3: Check to ensure you aren’t melting your mold (mainly plastic mold), and your resin isn’t hot and smoking.

If things look good, then turn the oven off and let it cool. You can repeat this process if you’re pouring another resin layer.

⚠️ IMPORTANT: Only do this with an oven that you won’t use for food again. An inexpensive toaster oven works great for this.

And if you don’t have toaster oven to dedicate for this project, here are some other ways to make resin dry faster.

Want to make something with resin molds but unsure where to start?

Then you’ll want to get a copy of my ebook, Resin Fundamentals. I’ve taken my 17 years of experience and condensed it into the essential details of resin crafting. Buy the PDF book now, and get a download link in minutes.

Unpublished Blog Posts of Resin Obsession, LLC © 2023 Resin Obsession, LLC

You say you need a flexible mold. However, I just bought a resin ornament made from an antique butter mold. Comments? How would you remove it? What protection would you need to do to the antique butter mold to ensure it was usable multiple times (not for butter)? I’d like to use my old butter molds and springerle molds to make ornaments with resin.

Hi Lisa, I haven’t used butter molds with resin, but this article might give you some ideas: https://www.resinobsession.com/resin-tutorials/how-to-use-cookie-cutters-as-resin-molds/

How often do you apply the demold spray? Every time?

Yes Linda, every time.

Late to answer, but I think the ornament from the butter mold was not cast directly from the mold itself. I would use an intermediate casting or molding material to make a cast, then make a flexible mold from the cast, using it to finally cast the resin. Just speculation on my part, but how I would think of using an inflexible mold.

If you buy a mold can you sell products you make with that mold?

Hi Martin, the answer is yes, unless the mold has a copyrighted design not authorized by the copyright holder.

Do you have thoughts on a finishing resin for polymer clay jewelry, etc. How to apply, how to clean a brush/other applicator, how to assure the resin will not stick to a support, applying earring backs. Thanks

Hi MJ, the Resin Obsession crystal doming resin works great for applying a glossy finish to polymer clay jewelry projects. You can buy it in our store here: https://shop.resinobsession.com/collections/resin/resin-obsession-crystal-doming-resin

I have several molds that tend to be not shiny at the base of what I’m making. The mold seems to be very thin on bottom and thicker higher up. Also have dull spots. I do clean them with soap and water, but the dullness remains. Any thoughts?

Hi Wilbert, it sounds like your molds are worn out.

Can I use plastic candy molds for a one time use with UV resin?

Hi Katherine, I’m a beginner, and I’m not sure which resin I should be using for molds, please help me. Thank you.

Hi Diane, since you’re working in molds, you need to use one designed for those. We’ve got two. The one you use comes down to how much resin you’re mixing and pouring at once.

For pours of 3 ounces or less, the Resin Obsession super clear resin is what you want: https://shop.resinobsession.com/collections/resin/resin-obsession-super-clear-resin

For pours of 3 ounces or more, the Resin obsession deep pour casting resin works great: https://shop.resinobsession.com/collections/resin/resin-obsession-deep-pour-resin

If you need help figuring out how much resin you need, our free resin calculator can do it for you: https://www.resinobsession.com/resin-calculator/

I used resin for the first time. I used a 6×6 resin canvas with trinkets on top. I had the canvas on 2×4 block so that I could get it on the sides. Now it’s stuck to the 2×4. Any suggestions?

Hi Karen, you can attempt to cut the wood away with a utility knife.

I have been doing this for a year now I have not tried to make my own molds would like to try will buy your mold kit hope it works ok.

I’ve seen a few videos of people painting the molds before pouring. Does that really work? Does it last?

Yes, you can do that! Painting your molds with a mica powder will make you project pop!

Just finished my first set of pendant molds. I used toothpick to swirl the colors, left a mark in bottom of mold that now transfers to each new project. How do I correct that? Not a tear, cut, or rip it is just a mark like a smear??? Any help would be appreciated!!!

I have a few options to try:

1. Polish the Mold Surface:

How to do it: You can try gently buffing or polishing the mark out of the mold using a very fine-grit sandpaper (like 2000 grit) or a soft polishing cloth. Be sure to work carefully and gently, as silicone molds are sensitive, and over-sanding could create new imperfections.

Pro tip: Use a small amount of mold polish or a bit of water while sanding to help smooth out the mark without creating new scratches.

2. Apply a Mold Release Spray:

Why it helps: A good mold release agent can sometimes help fill in minor imperfections like smears or marks. It creates a barrier between the mold surface and the resin, helping to smooth out any small blemishes during the casting process.

How to do it: Spray or brush a thin layer of mold release on the inside of the mold before your next pour. This can help the resin to settle more evenly and prevent the mark from transferring to the next piece.

3. Coat the Mold with a Thin Layer of Resin:

How to do it: If the mark isn’t too deep, you can try applying a very thin layer of resin to the mold itself. Use a soft brush to apply a small amount of clear resin over the affected area and let it cure fully. This can sometimes fill in the mark and smooth out the surface.

Pro tip: Make sure the resin layer is as thin as possible to avoid changing the shape of the pendant or introducing new issues.

4. Mold Replacement (Last Resort):

If the mark is stubborn and can’t be removed, you might consider retiring that mold for pendants where the bottom is visible and keeping it for other projects where the bottom imperfections won’t show (like when backings or embellishments are added).

These techniques should help reduce or eliminate the mark in your mold so it doesn’t affect future pours. Let me know which method works for you!